A driving device for grinding brake discs

A driving device and brake disc technology, which is applied to grinding/polishing safety devices, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of unguaranteed processing quality of brake discs and difficult processing of brake discs. , to achieve the effect of saving manpower and material resources, high degree of automation, and simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of technical personnel.

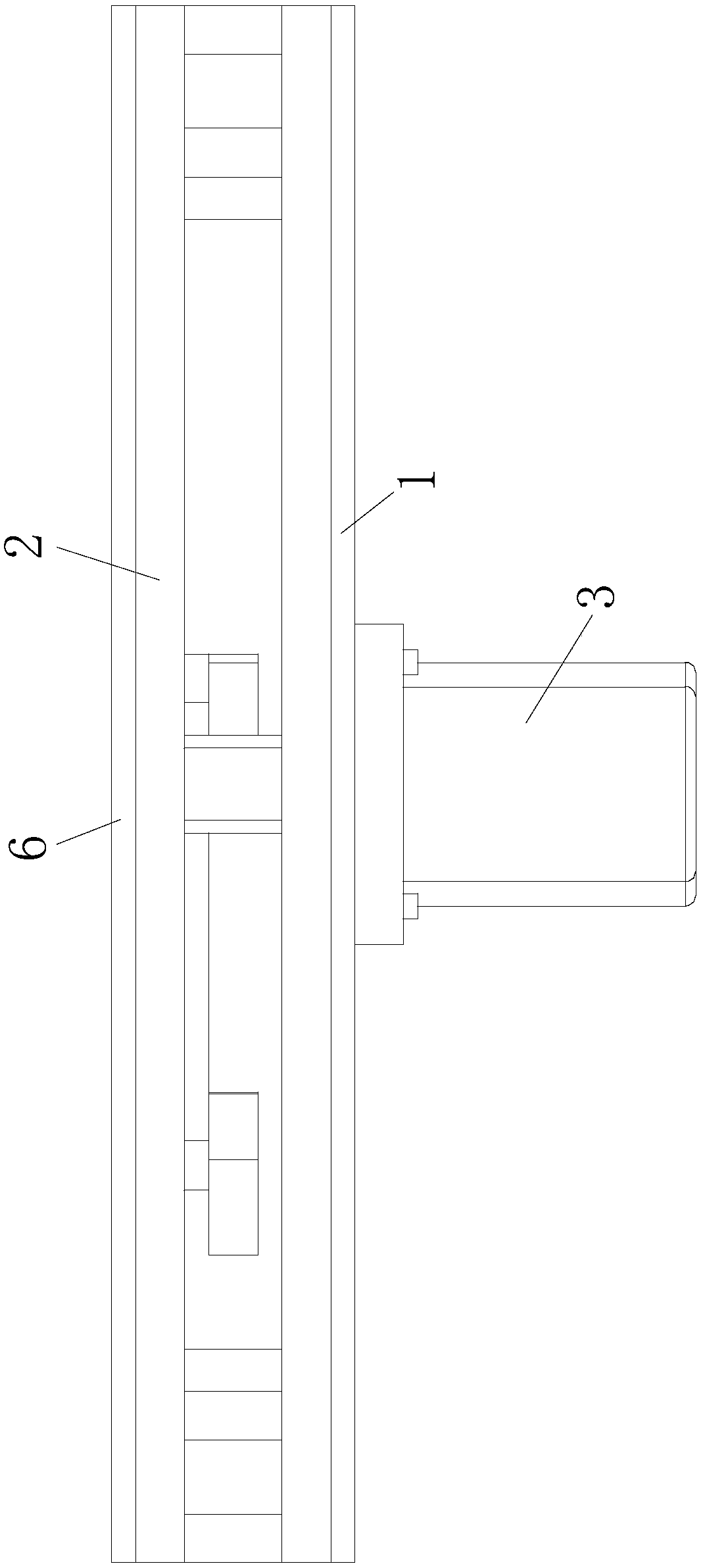

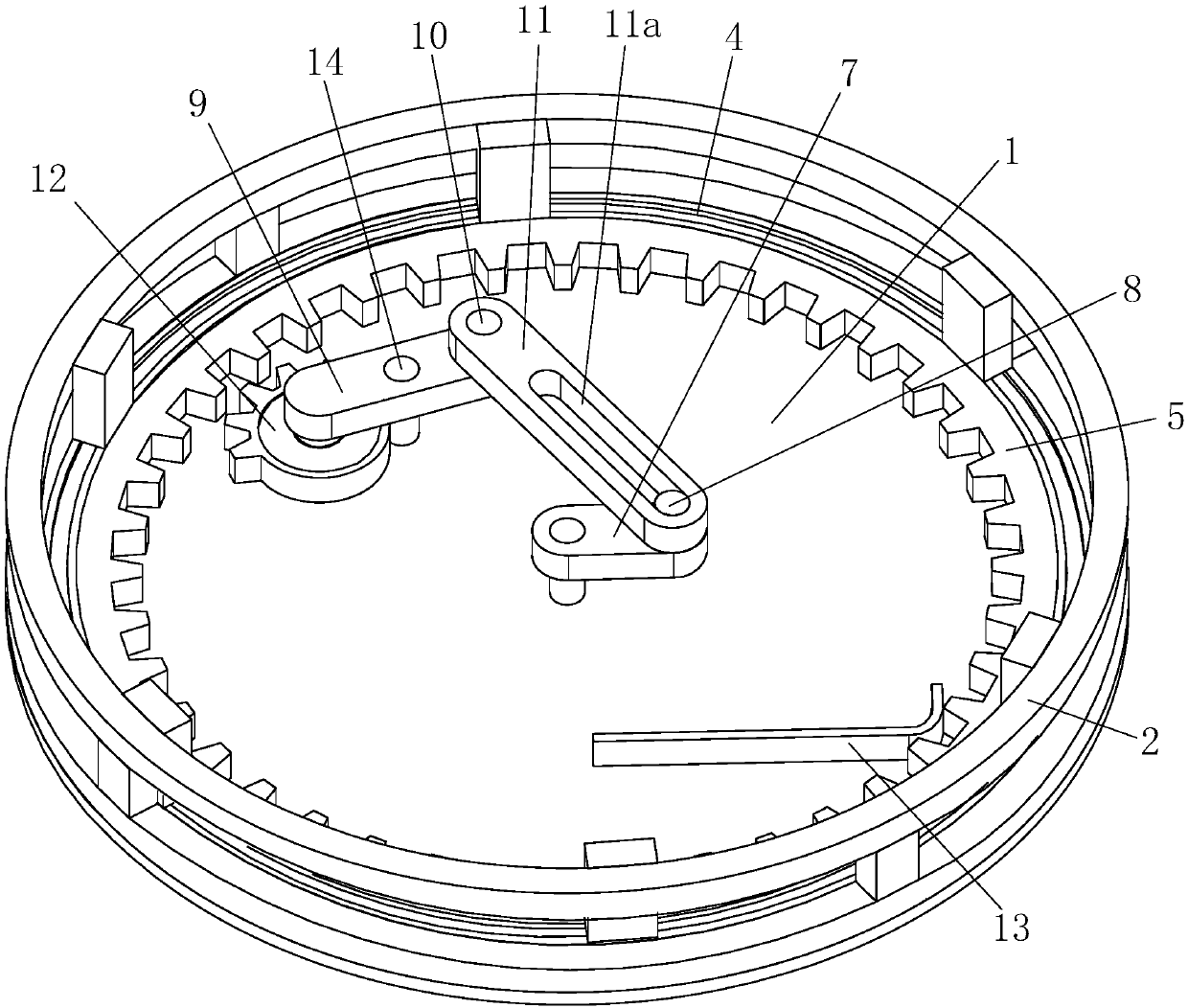

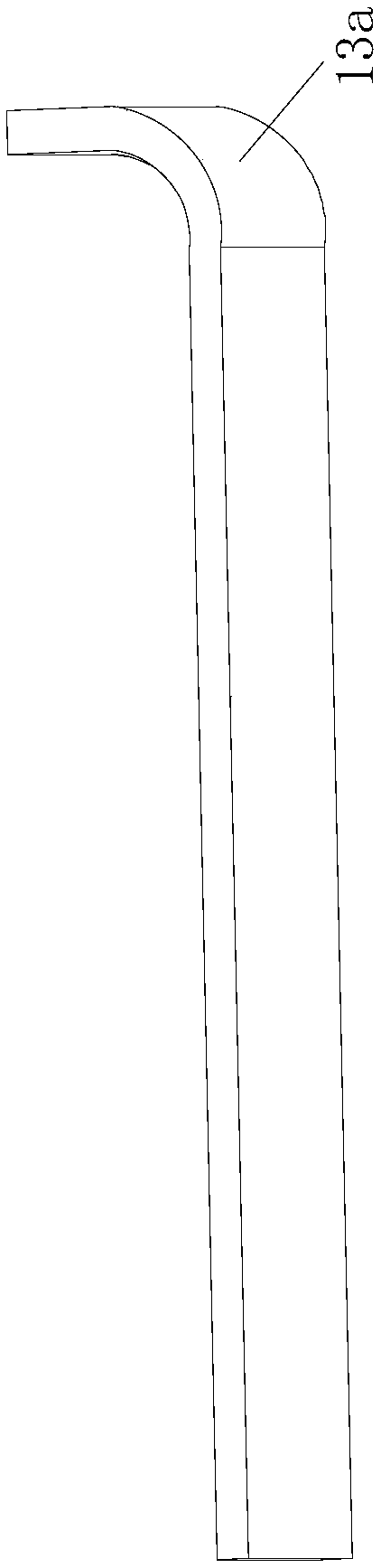

[0016] Such as Figure 1 to Figure 3 As shown, a driving device for brake disc grinding includes an upper end plate 6, a support frame 2, a motor 3, a lower end plate 1, a bearing 4, a ring gear 5, a drive plate 7, a No. 1 connecting shaft 8, a vertical shaft 14, Connecting plate 9, No. 2 connecting shaft 10, driven plate 11, driving wheel 12 and elastic flap 13, described lower end plate 1 is fixed on the lower end of support frame 2, and described motor 3 is fixed on the lower end of lower end plate 1, so The bearing 4 is fixed on the inner wall of the support frame 2, the ring gear 5 is fixed on the inner wall of the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com