Residue and juice separating device

A technology for separation and meshing of slag juice, which is applied in beverage preparation devices, household utensils, household machinery for filtering food, etc. It can solve the problems of affecting the taste and quality of juice, complicated operation, and difficult cleaning work, and achieves the effect of being easy to clean Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

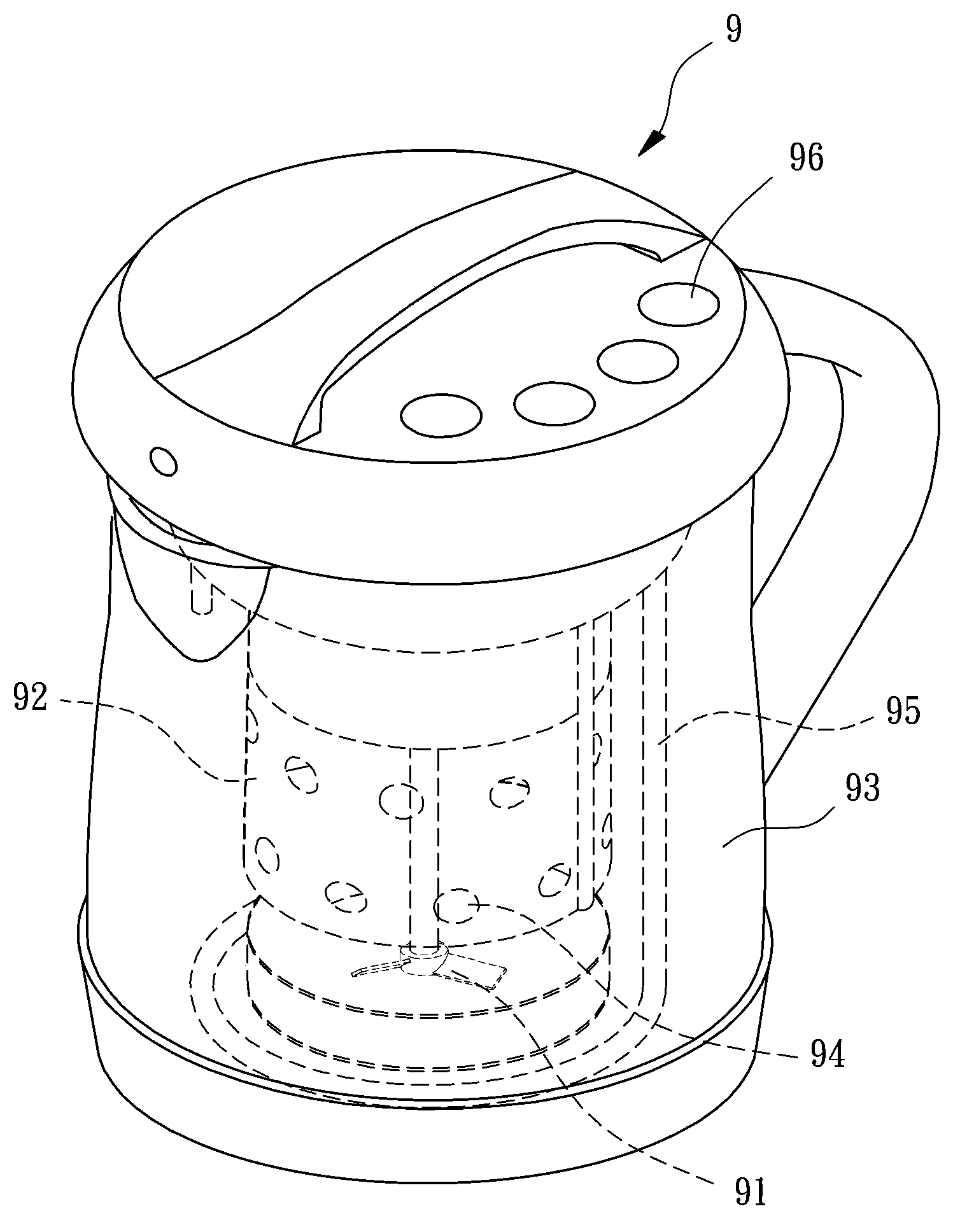

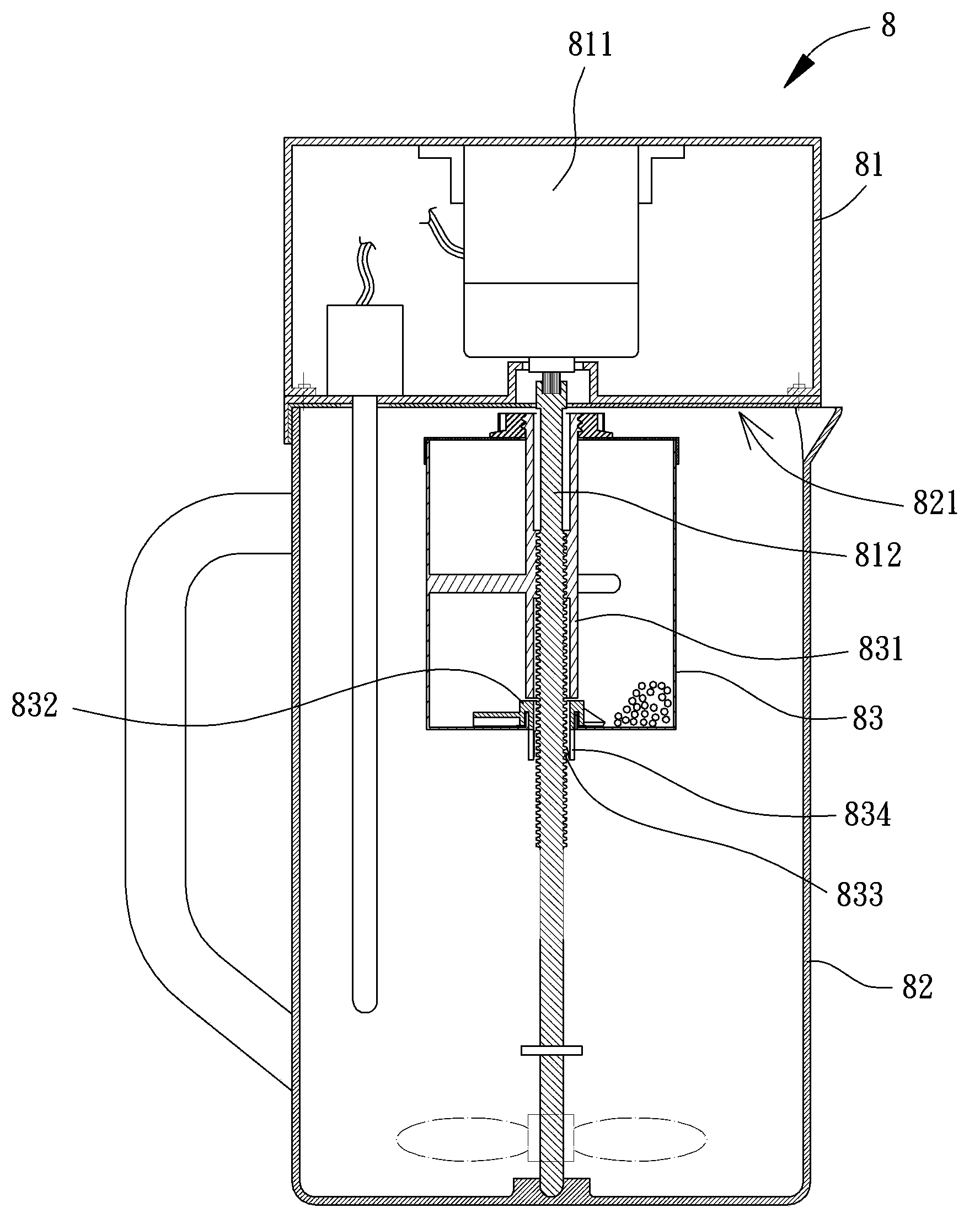

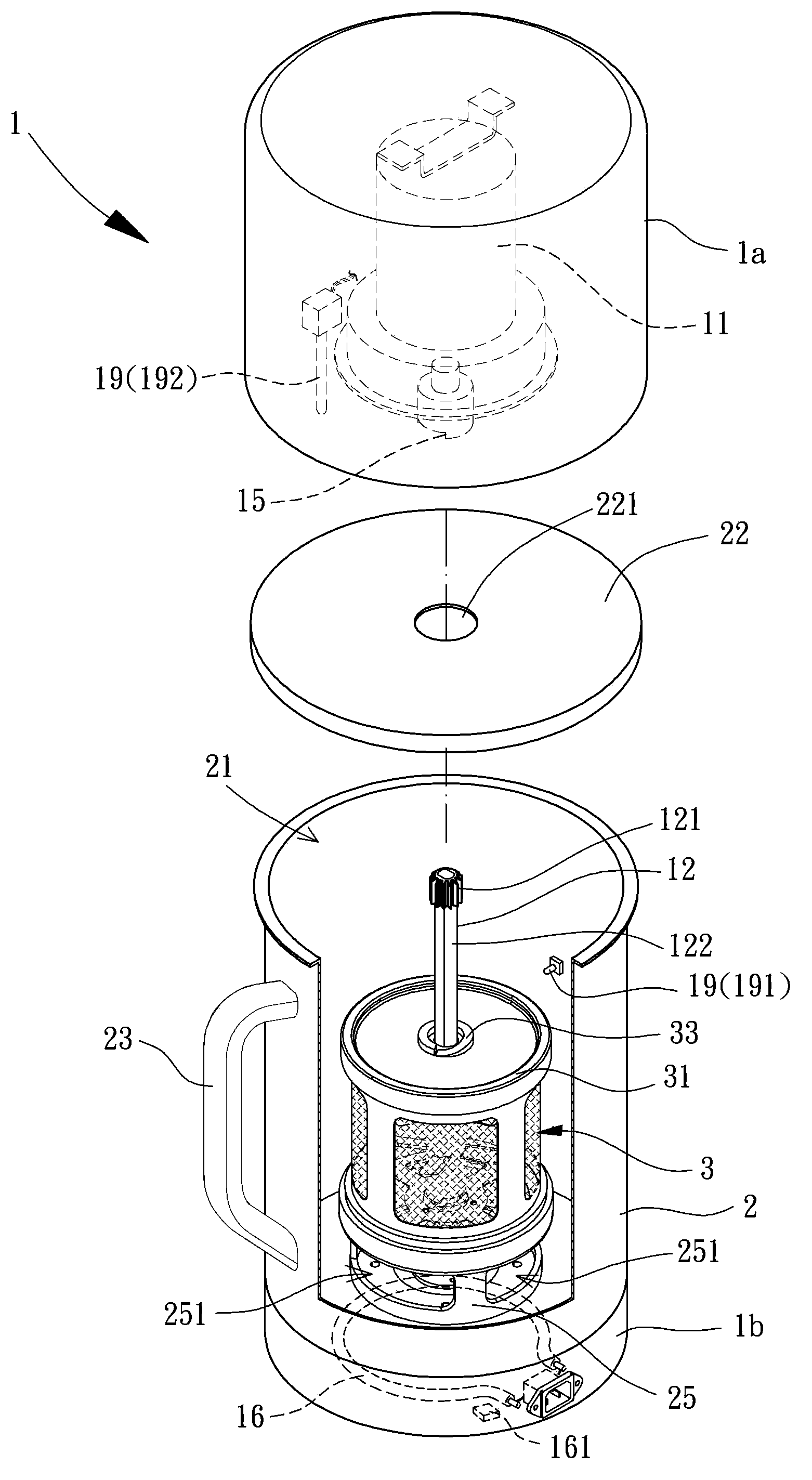

[0078] see image 3 , 4 As shown, it is the first preferred embodiment of the present invention, and the slag juice separation device of this embodiment includes a machine base 1 , a container 2 and a slag collecting member 3 . The container 2 can be combined with the machine base 1, the slag collecting member 3 can be accommodated in the container 2, and the slag collecting member 3 can be driven by a rotating shaft 12 of the machine base 1. The container 2 moves axially and rotates radially.

[0079] The base 1 is provided with a power element 11, and the power element 11 can directly or indirectly drive a rotating shaft 12 to rotate in a first direction or a second direction. The power element 11 can be an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com