Automatic snake-shaped spring production equipment

A technology of serpentine springs and production equipment, which is applied in the field of automatic serpentine spring production equipment, to achieve the effects of reduced production costs, simple operation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

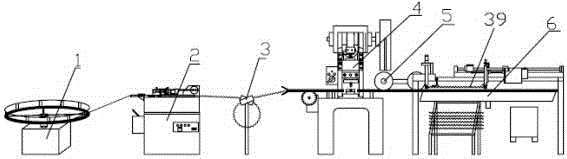

[0016] Such as figure 1 , 2 , 3, 4, 5 and 6: the automatic serpentine spring production equipment of the present invention is successively provided with a pay-off reel 1, a serpentine spring bending machine 2, a buffer 3, and a cutting machine 4 from the previous process to the subsequent process , Two spring delivery wheels 5 and an automatic detection adjustment device 6.

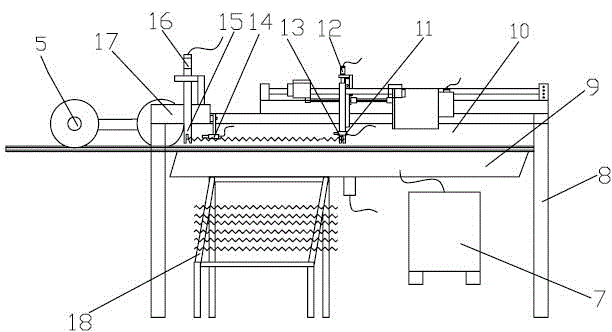

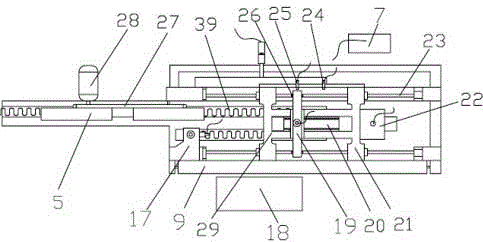

[0017] Automatic detection and adjustment device 6 is made up of detection and adjustment equipment 10, intelligent controller 7 and blanking frame 18, and described detection and adjustment equipment 10 comprises movable regulator 29, fixed regulator 17 and workbench 8, and described movable regulator 29 is set In the middle of the workbench 8, the fixed adjuster 17 is located at the lower left corner of the workbench 8.

[0018] Both sides of movable adjuster 29 are provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com