Reinforcement structure of rear tailgate of vehicle

A technology for strengthening components and vehicles, which is applied to vehicle components, doors, transportation and packaging, etc., and can solve problems such as increased weight, inability to reduce displacement, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be described in detail based on the embodiments shown in the drawings.

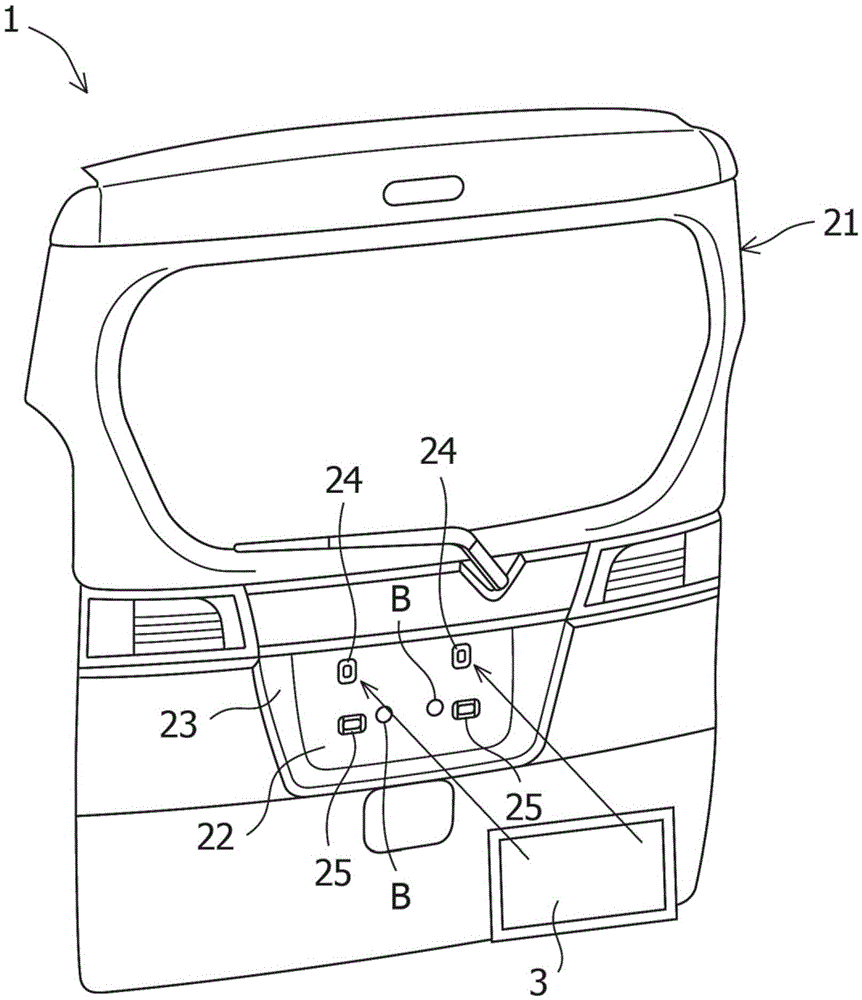

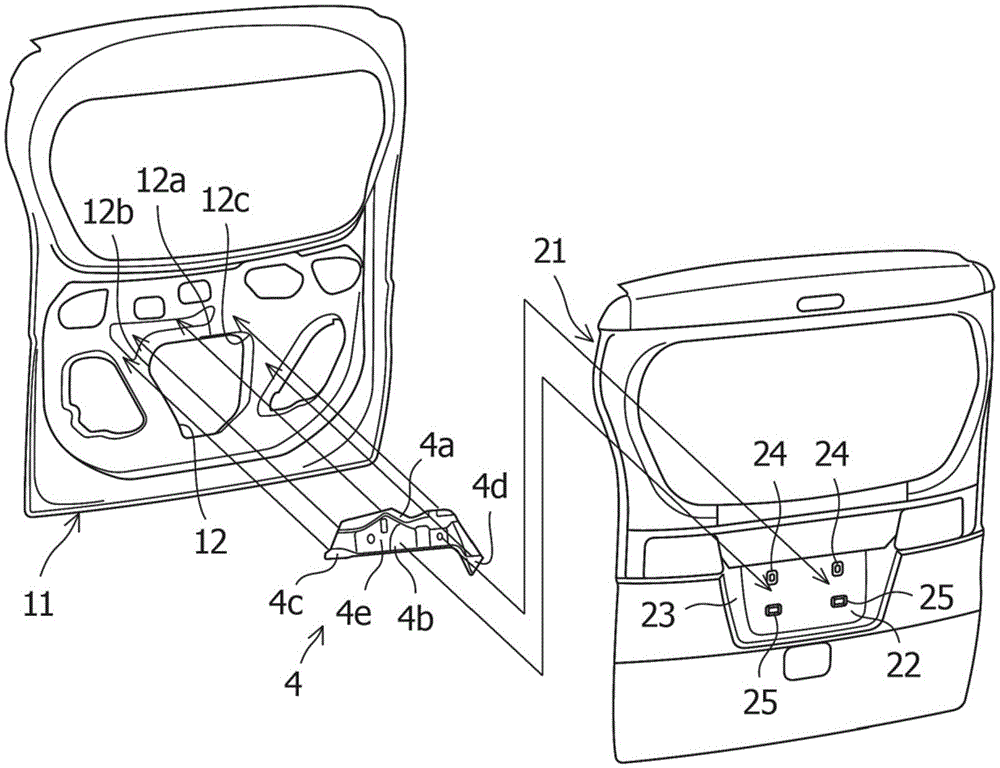

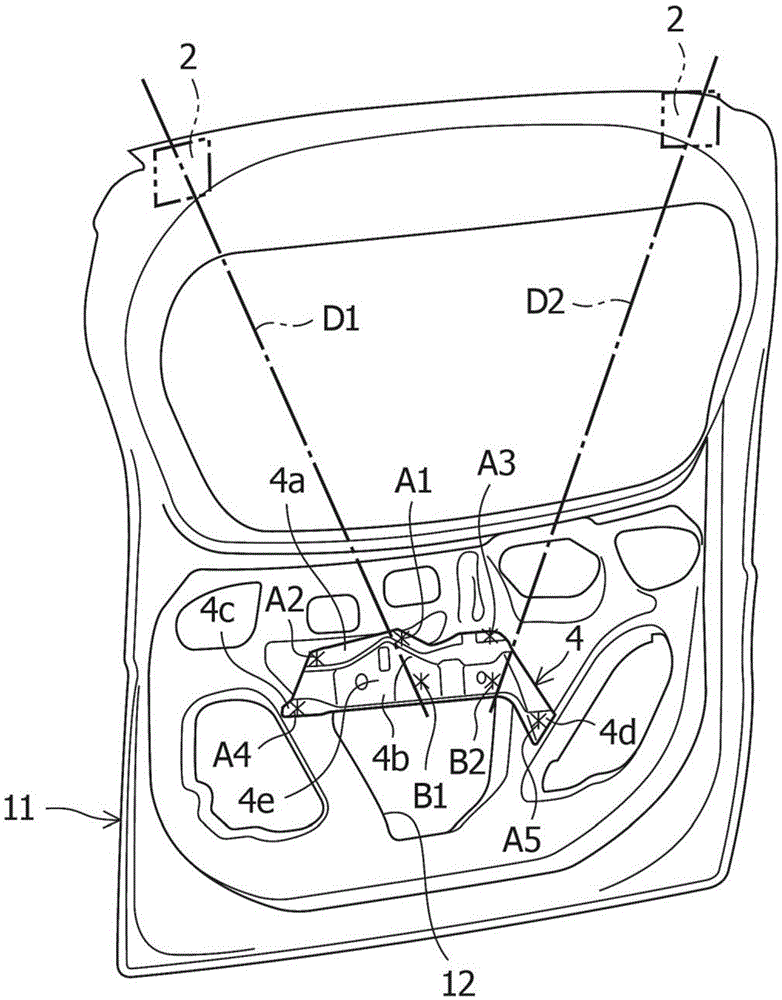

[0031] Figure 1 to Figure 5 The rear door reinforcement structure of the vehicle which shows embodiment of this invention.

[0032] like Figure 1 ~ Figure 3 As shown, the vehicle to which the rear door reinforcement structure according to the embodiment of the present invention is applied is a hatchback type vehicle in which the rear door 1 for opening and closing the door opening (not shown) at the rear of the vehicle body is opened upward. . Therefore, the tailgate 1 is rotatably attached to the rear of the vehicle body via a pair of left and right door hinges 2 provided on the upper part of the vehicle body, and is configured to rotate around the door hinges 2 when opening and closing the door opening. A pair of left and right door hinges 2 that support the rear tailgate 1 in a rotatable manner are arranged at intervals in the vehicle width direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com