Automatic bagging packing machine

A packaging machine and automatic technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of easy warping and bending of packaging bags, difficult to ensure the display state of packaging materials, and movement of packaging bags, etc., to achieve good packaging quality. , novel design, compact process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

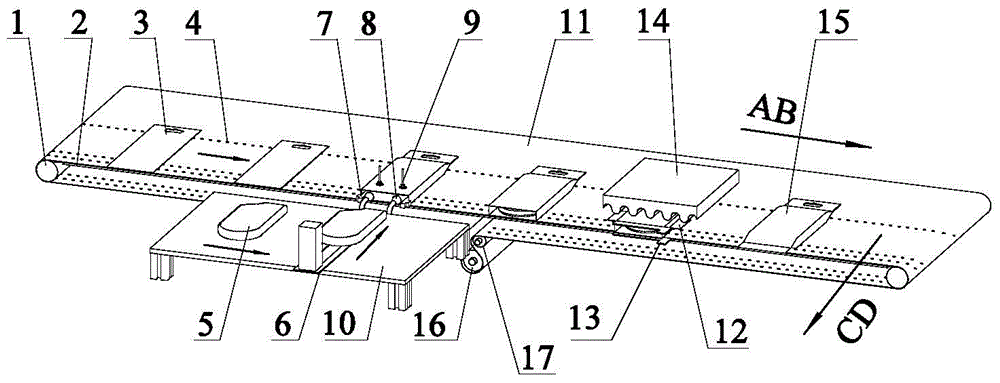

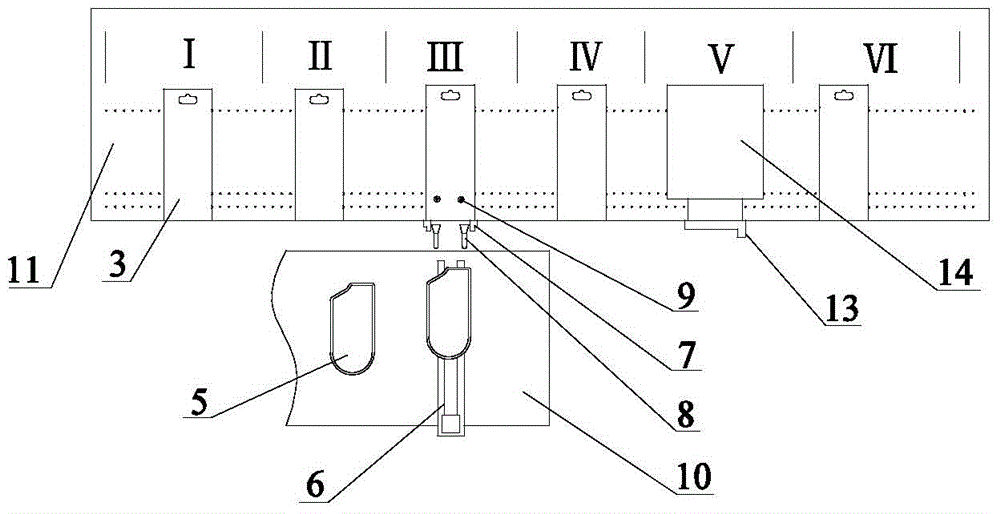

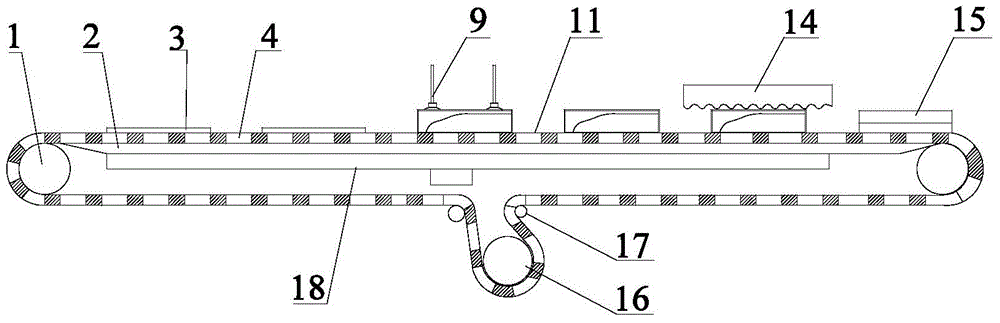

[0025] Such as figure 1 As shown, the direction of the arrow AB is expressed as horizontal, and the direction indicated by the arrow is the front; the direction of the arrow CD is vertical, and the direction indicated by the arrow is ahead; Vacuum suction bag opening device, lead-in filling device and hemming exhaust sealing device; the leading-in filling device is installed vertically above the package supply device, and the vacuum suction bag opening device and hem-folding device are installed horizontally and frontally above the suction conveying device. The air sealing device, the vacuum suction bag opening device and the lead-in filling device are in the vertical docking position;

[0026] Such as Figure 1 to Figure 3 As shown, the packaging supply device includes a conveying panel 10 arranged parallel to the lateral direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com