An indexing variable speed conveying device for flexible materials

A technology of variable-speed conveying and flexible materials, which is applied in the directions of transportation and packaging, sending objects, and thin material processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

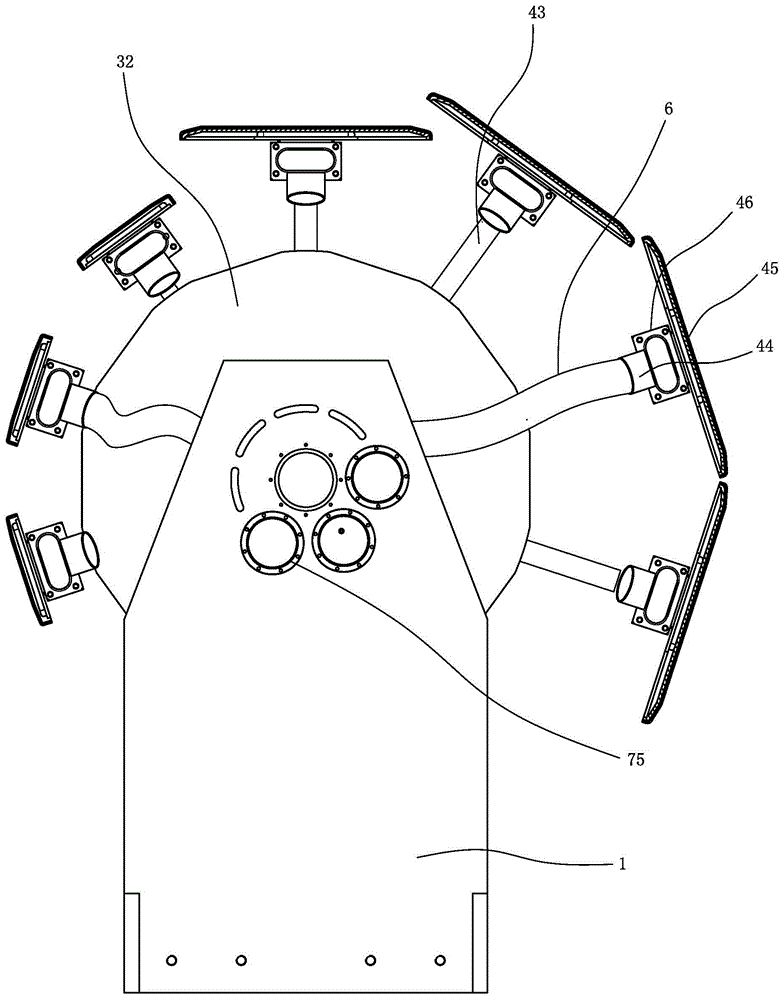

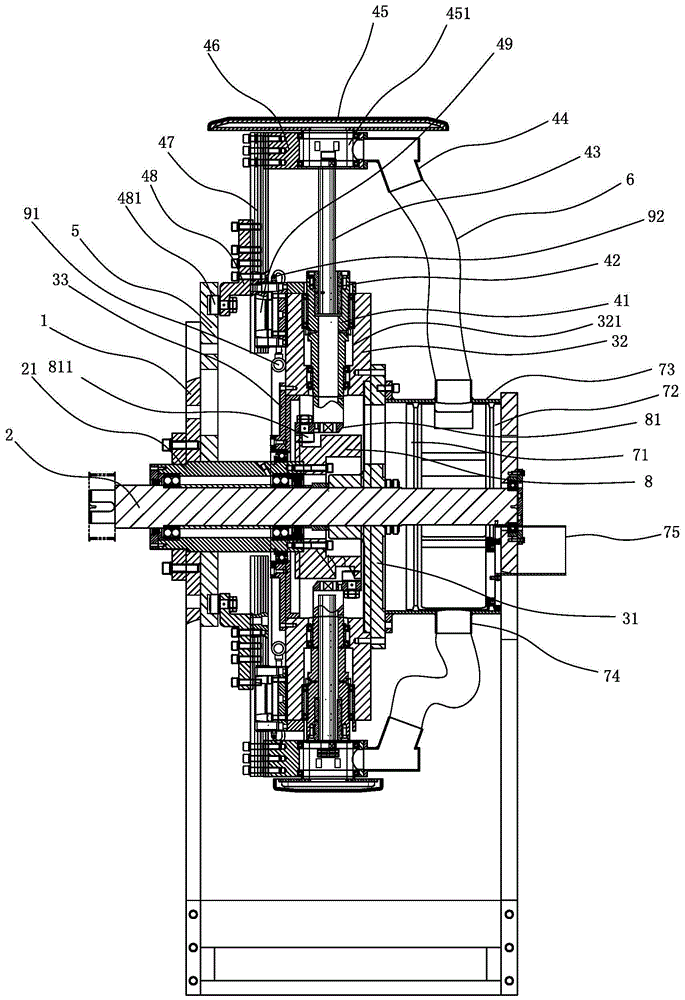

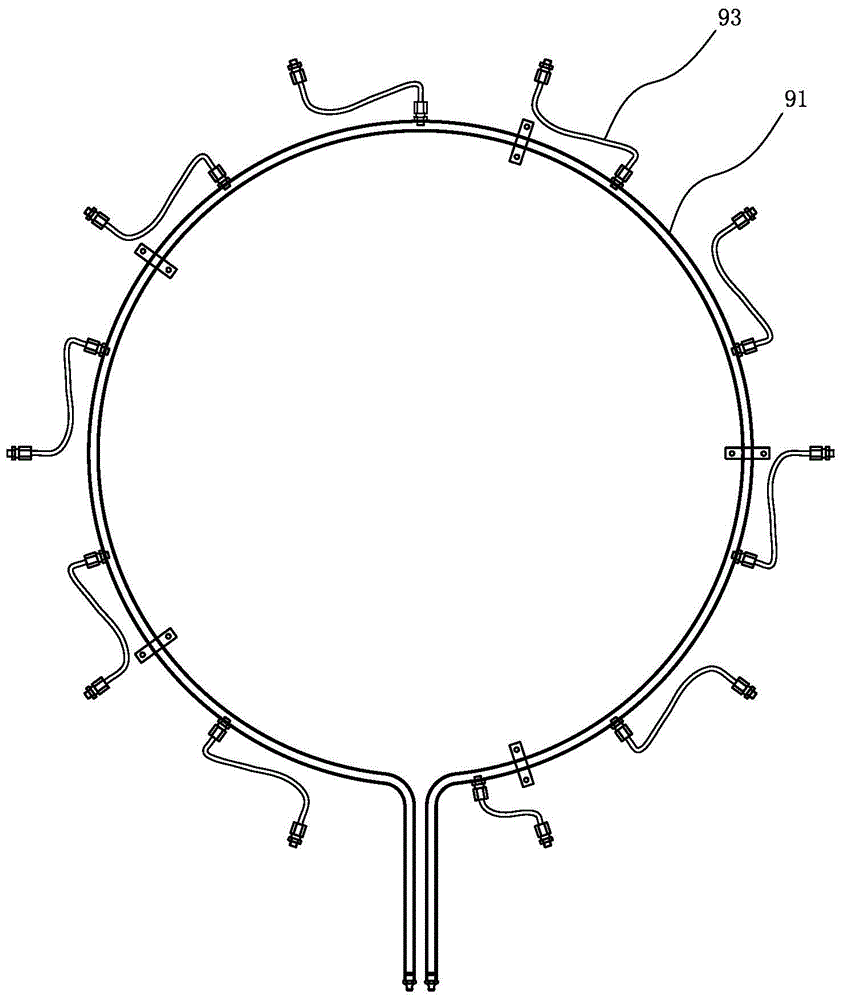

[0020] refer to figure 1 , figure 2 with image 3 As shown, an indexing variable speed conveying device for flexible materials includes a frame 1, a main shaft 2, a slewing frame, a plane cam 5, a cylindrical cam 8, several sets of adsorption indexing mechanisms and a rotary negative pressure mechanism.

[0021] Frame 1 is made up of two side plates arranged at intervals and a bottom plate connected between the two side plates. Between the two side plates, the main shaft 2 is driven to rotate by the drive motor (not shown in the figure) during work; The annular supporting disc 33 arranged on the shaft sleeve 21 is composed of the hub 32 arranged between the transmission disc 31 and the supporting disc 33. The circumference of the hub 32 is distributed with several mounting holes 321 extending radially. The plane cam 5 is fixedly arranged on the On the side plate of the frame 1 , the cylindrical cam 8 is coaxially arranged on the shaft sleeve 21 with the main shaft 2 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com