Ignition Method of Plasma Hall Thruster

A Hall thruster, plasma technology, applied in the direction of using plasma, thrust reverser, machine/engine, etc., can solve the problems of complex ignition power technology and large mass, so as to reduce the mass of the payload and save the ignition power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

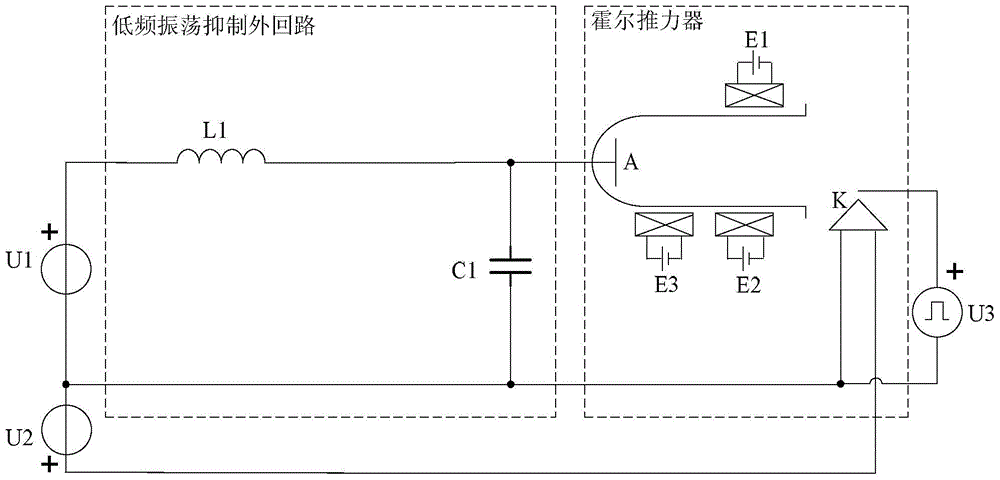

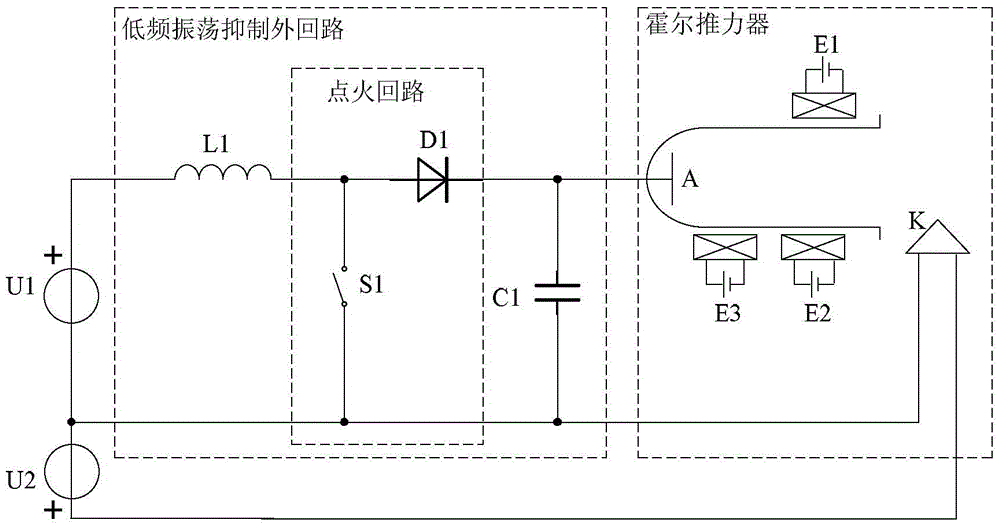

[0014] Specific implementation mode one: the following combination figure 2 Describe this embodiment, the plasma Hall thruster ignition method described in this embodiment, the method is: add an ignition circuit to the low-frequency oscillation suppression outer circuit to replace the ignition power supply U3;

[0015] The ignition circuit includes a controllable switch S1 and a diode unit D1, the diode unit D1 is connected in series between the filter inductor L1 and the anode A; one end of the controllable switch S1 is connected to the common node of the filter inductor L1 and the diode unit D1, and the controllable switch S1 The other end of is connected to the common node of the filter capacitor C1 and the discharge power supply U1;

[0016] The plasma Hall thruster ignition method comprises the following steps:

[0017] Step 1, the heating power supply U2 heats the cathode K to reach the ignition temperature;

[0018] Step 2, control and close the controllable switch S...

specific Embodiment approach 2

[0023] Specific embodiment two: this embodiment will further explain the first embodiment, the diode unit D1 is composed of multiple diodes in series, and the reverse cut-off voltage of the diode unit D1 is greater than the voltage U across the ignition power supply U1 1 .

specific Embodiment approach 3

[0024] Specific implementation mode three: this implementation mode further explains implementation mode one, the capacitance value C of the filter capacitor C1 1 =100nF, the inductance value L of the filter inductor L1 1 =10mH, DC resistance R of filter inductor L1 0 =0.01Ω, the voltage U across the discharge power supply U1 1 =350V, T1=1ms.

[0025] Using the parameters set in this embodiment, using Simulink simulation, the ignition voltage U(t)=10000V 35 μs after the controllable switch S1 is turned off. Can quickly meet the ignition voltage requirements. The established strong electric field makes the Hall thruster ignite successfully, thereby saving the design of the ignition power supply, making the ignition design of the Hall thruster simple, and saving the weight of the high-voltage pulse ignition power supply.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com