Method for determining maximum stress value of prestress circular thin film under uniformly-distributed loads

A technology of evenly distributed load and maximum stress, applied in the direction of measuring force, instruments, measuring devices, etc., can solve problems such as loss of instrument accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

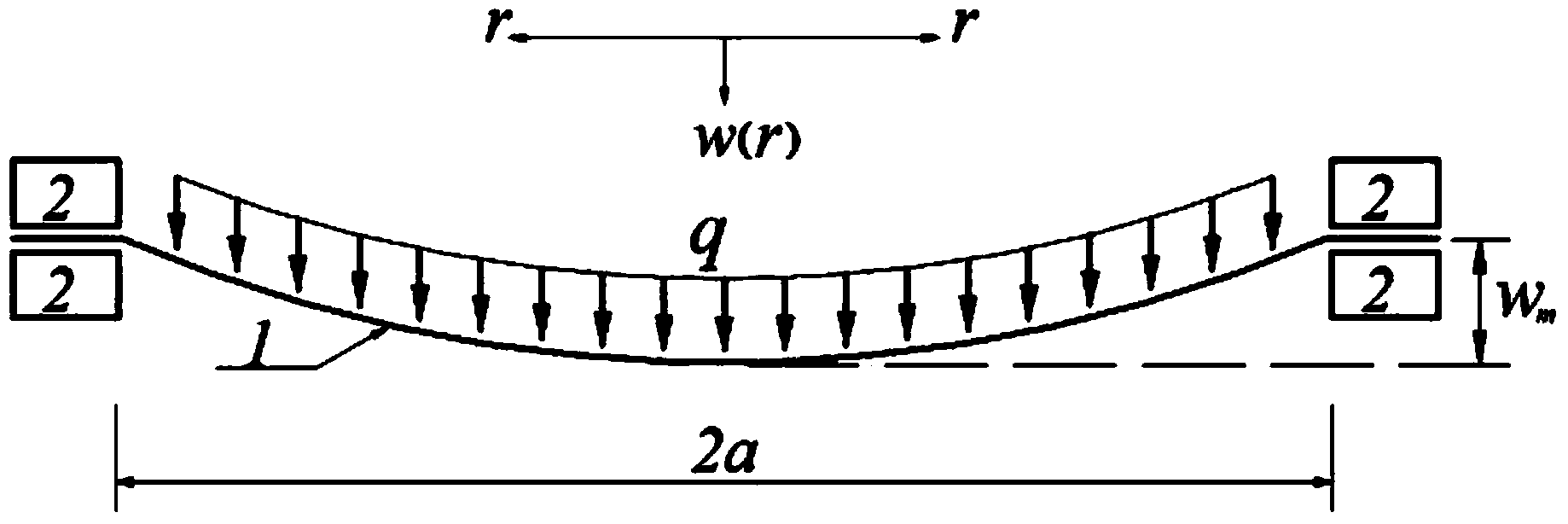

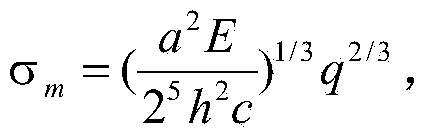

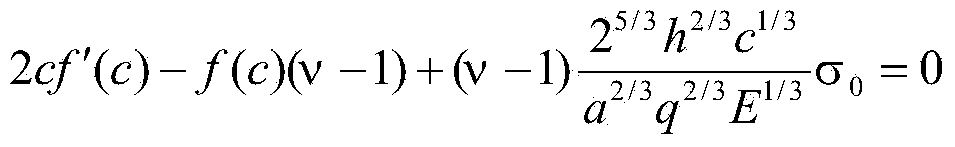

[0016] Such as figure 1 As shown, the radius is a, the thickness is h, Young’s modulus of elasticity is E, Poisson’s ratio is ν, and the prestress is σ 0 The circular membrane is fixed and clamped at its circumference, and a transverse uniform load q is applied to it, then based on the static force balance analysis of the axisymmetric deformation problem of the circular membrane, the maximum stress value σ of the membrane is calculated using the load measurement value q m can be determined by the following formula:

[0017] σ m = ( a 2 E 2 5 h 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com