A gas chromatograph for hydrocarbon component analysis of a catalytic cracking product of gasoline and diesel

A gas chromatograph and catalytic cracking technology, which is applied in the direction of analyzing materials, instruments, scientific instruments, etc., can solve the problems of complex design and configuration of twelve-way valves, and achieve the effect of simple structure, simple operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

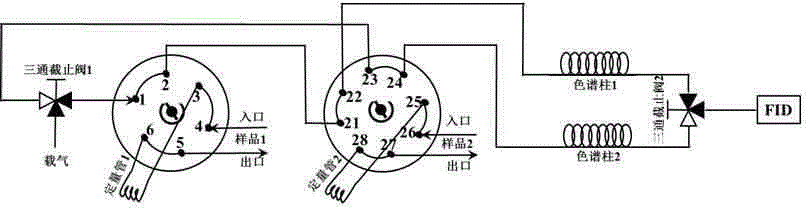

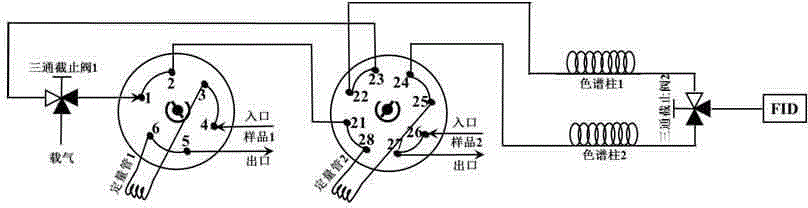

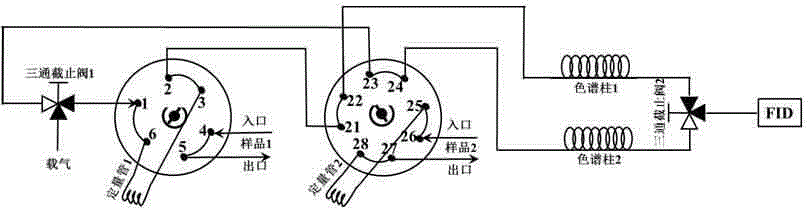

[0030] refer to figure 1 , the instrument is in standby mode, the carrier gas N 2The circuit is: carrier gas inlet → three-way stop valve 1 middle path → three-way stop valve 1 right path → six-way valve channel 1 → six-way valve channel 2 → eight-way valve channel 21 → eight-way valve channel 22 → chromatographic column 1 → Three-way stop valve 2 left → three-way stop valve 2 middle → FID detector; sample 1 circuit is: six-way valve channel 4 → six-way valve channel 3 → quantitative tube 1 → six-way valve channel 6 → six-way valve channel 5. Sample 2 circuit is: eight-way valve channel 26→eight-way valve channel 25→quantitative tube 2→eight-way valve channel 28→eight-way valve channel 27; in column selection, from three-way stop valve 1 to chromatographic column 2 The detailed route to the three-way stop valve 2 is: three-way stop valve 1 left path → eight-way valve channel 23 → eight-way valve channel 24 → chromatographic column 2 → three-way stop valve 2 right path.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com