Laser point scanning oxygen, nitrogen, hydrogen, argon and helium joint measuring instrument and joint measuring method

A technology of laser point and joint measuring instrument, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of low reliability and poor accuracy of ion probes, and achieve the effect of improving analysis efficiency and convenient and simple sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

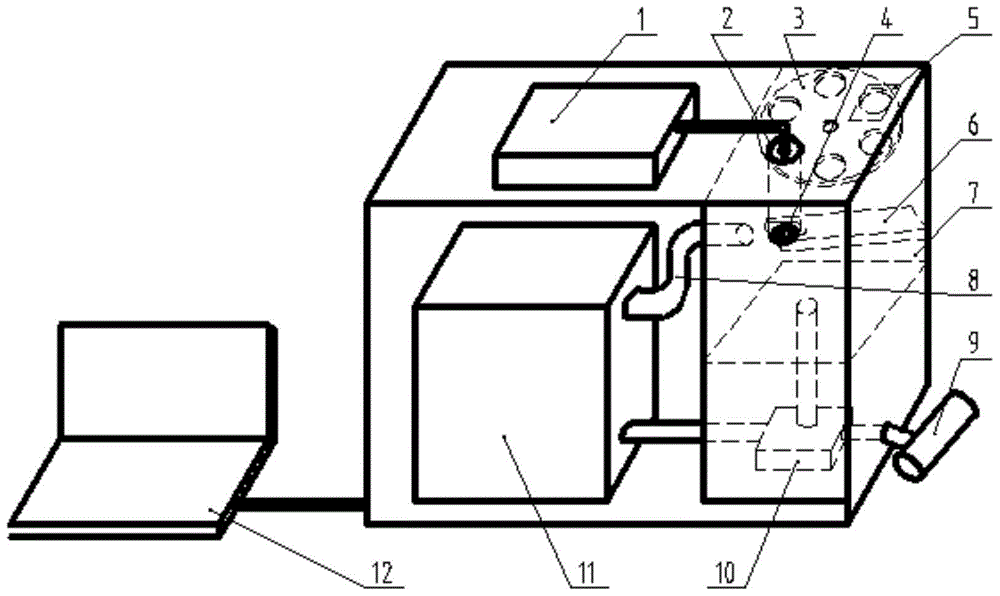

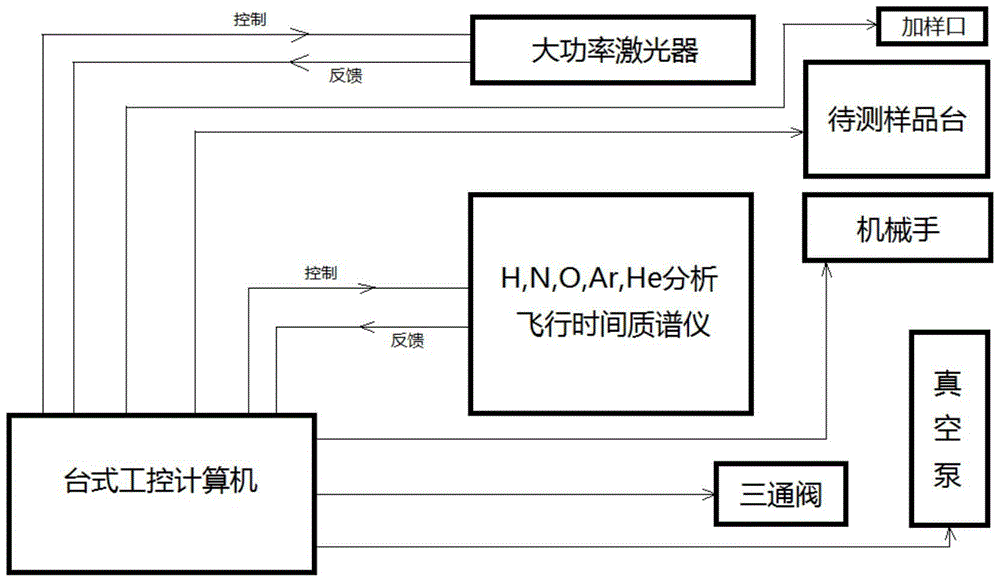

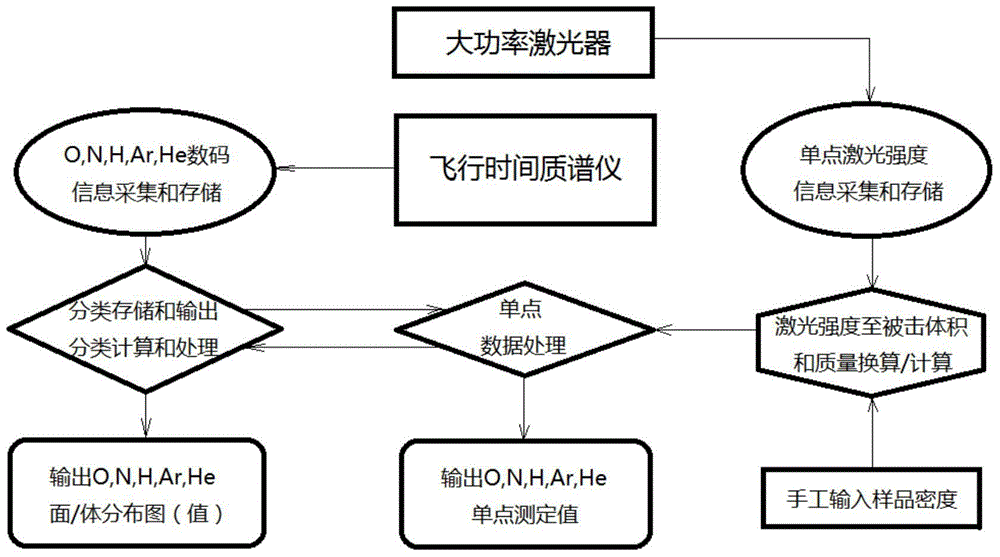

[0030] The invention puts the laser point scanning gas analysis technology and method into practice, and assembles a laser point scanning gas joint measuring instrument. Drawing on the experience of assembling laser (point melting)-gas chromatography hydrogen determination instrument, the hardware is planned to use high-power laser (power 0.1-20000W), mass spectrometer (pulse melting-) mass spectrometer gas analyzer, vacuum pump, metal antifouling filter Assembled with devices and manipulators. The software is divided into two parts: control software and data processing software. The control software of the joint tester can precisely control the actions of the laser, the sample platform to be tested, the sample injection port, the manipulator, the vacuum pump, and the three-way valve, and control the mass spectrometer to launch according to the settings. Current and other parameters to run. Data processing software processes all information and provides timely feedback; proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com