Two-dimensional angle adjusting frame

A two-dimensional angle, adjusting frame technology, applied in instruments, installation, optics and other directions, can solve the problems of high cost, insufficient rigidity of the adjusting frame, high processing requirements, etc., to reduce the matching accuracy, improve the rigidity and stability, and eliminate the gap. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific examples, but not as a limitation of the present invention.

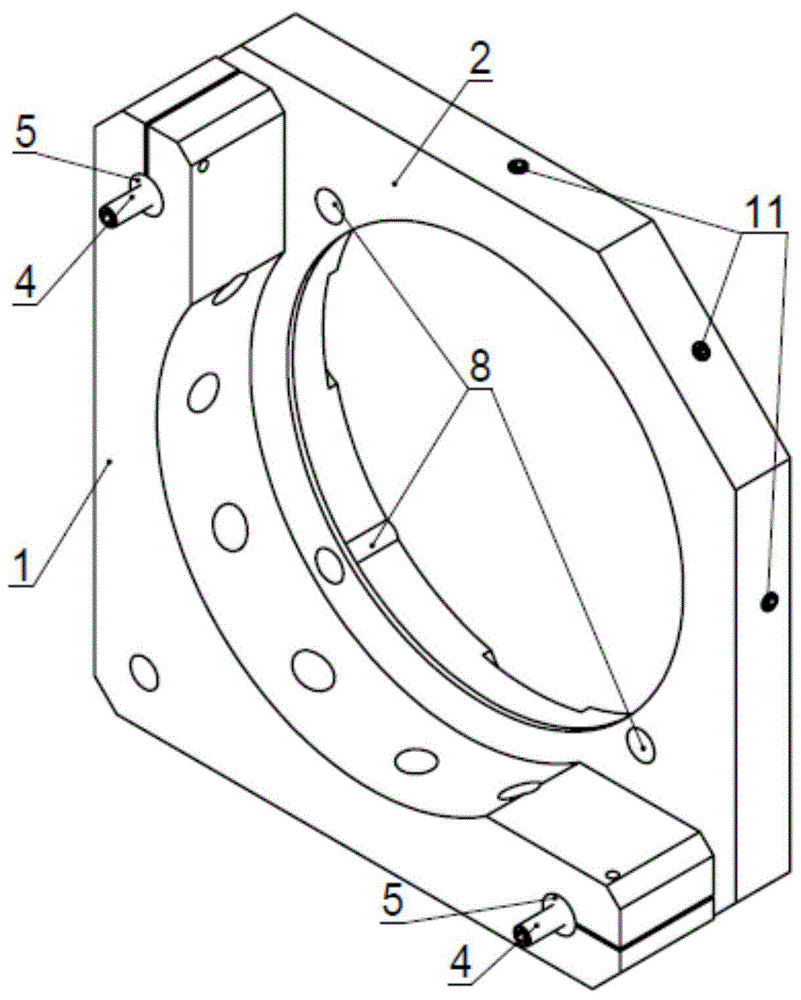

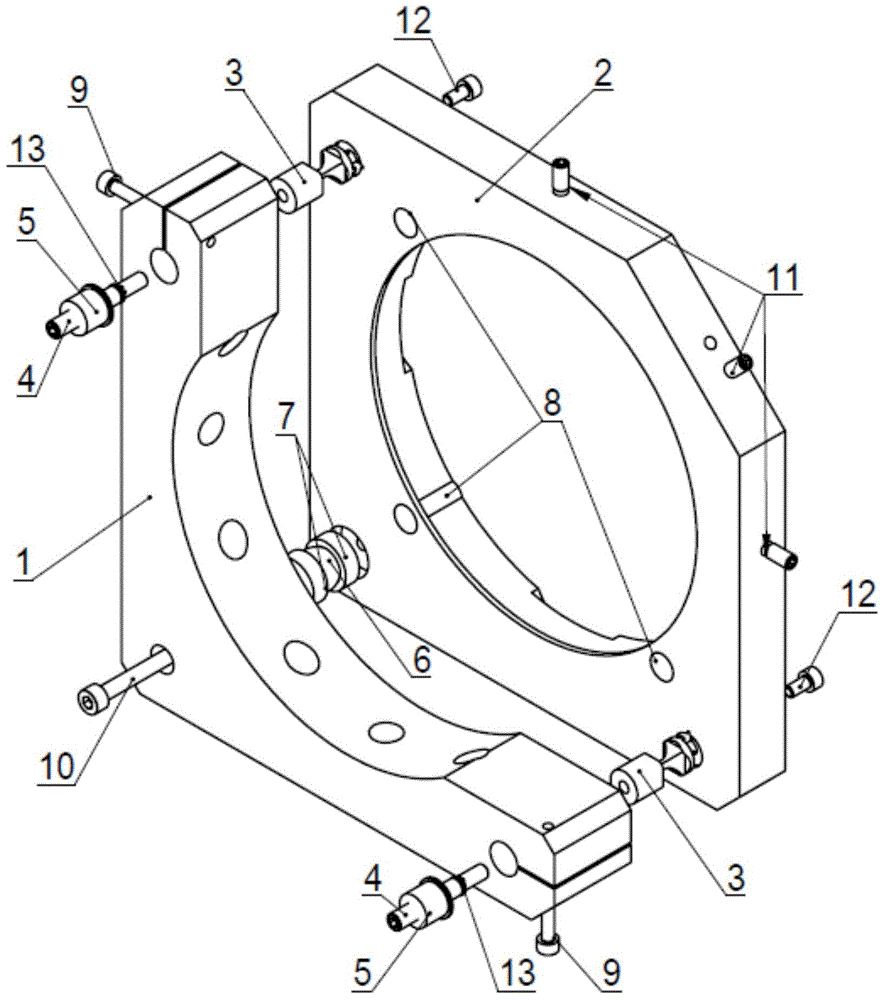

[0031] It can be seen from the figure that the embodiment of the two-dimensional angle adjustment frame of the present invention comprises an L-shaped base 1, an adjustment seat 2, two two-dimensional flexible hinges 3, two screw rods 4, two nuts 5, steel balls 6, two A ball pit 7, three positioning posts 8, two circlips 13, a first connecting screw 9, a second connecting screw 10, a fixing screw 11 and a third connecting screw 12;

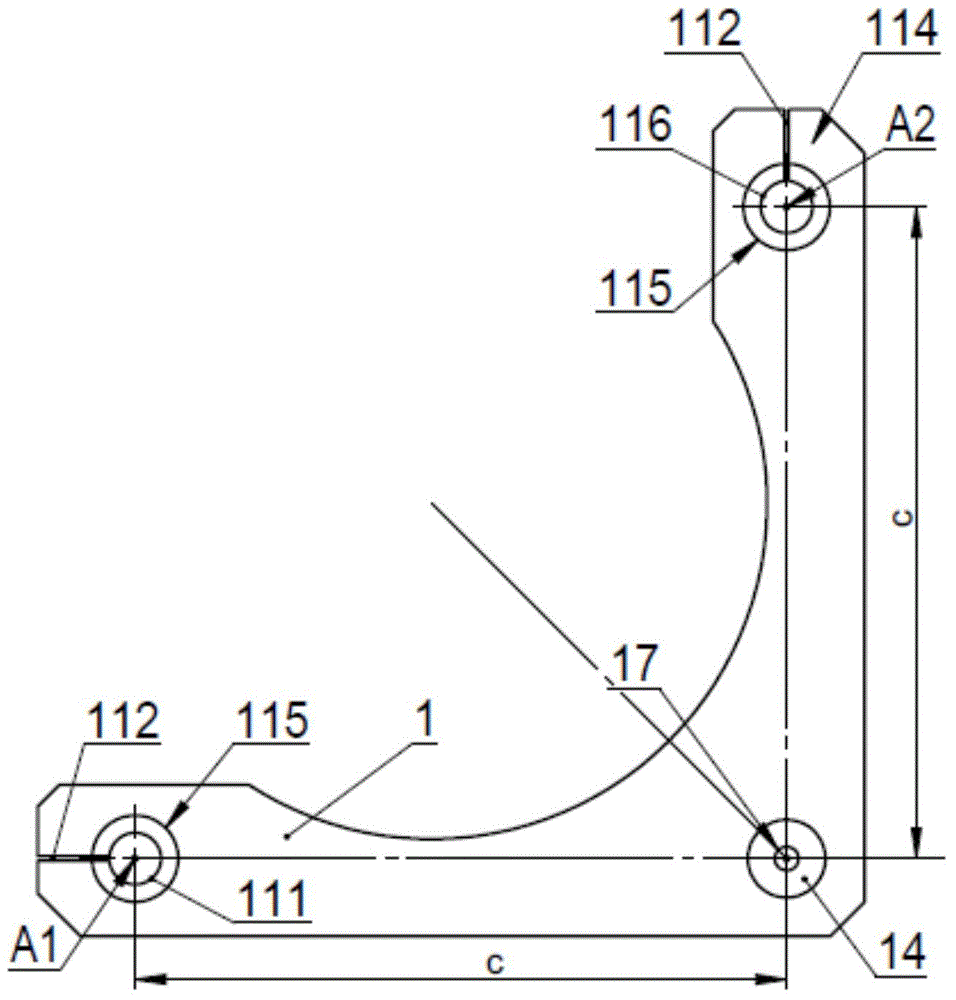

[0032] The corner of the L-shaped base 1 has a base ball pit hole 14, the two ends respectively have a first nut fixing hole 111 and a second nut fixing hole 116, and the middle of the adjustment seat 2 has an installation adjustment object The mounting hole 222 of the L-shaped base 1, the positions corresponding to the base ball pit hole 14, the first nut fixing hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com