System and method for intelligent warehousing checking

A technology of intelligent warehousing and warehouse, applied in the field of warehousing management, to achieve the effect of improving efficiency and precision and realizing intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

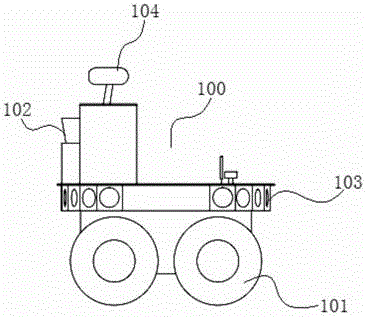

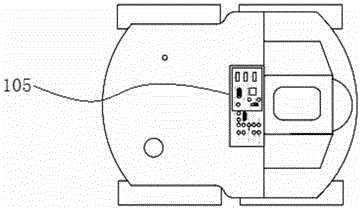

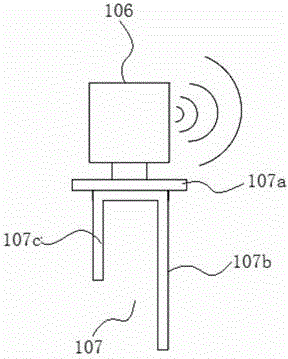

[0047] See figure 1 , Which shows the system block diagram of the intelligent warehouse inventory system provided by the present invention. As can be seen from the figure, the inventory system is mainly composed of an automatic inventory robot 100, a remote management server 200, and a cargo tag 300.

[0048] The goods label 300 is set on the corresponding goods or shelves, and is used to store relevant information of the corresponding goods. The goods tag 300 generally adopts an RFID tag, which stores shelf position information, the name of the goods, the storage status of the goods, storage time, operator information, etc.

[0049] The automatic inventory robot 100 is the core component of the entire system. In its working storage environment, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com