Automatic checking system for stereoscopic warehouse

A three-dimensional library and automatic technology, applied in image data processing, instruments, data processing applications, etc., can solve the problems of being unable to judge the number of stacked layers, unable to calculate the total number of stacked boxes, and narrow space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and example, the present invention will be further described:

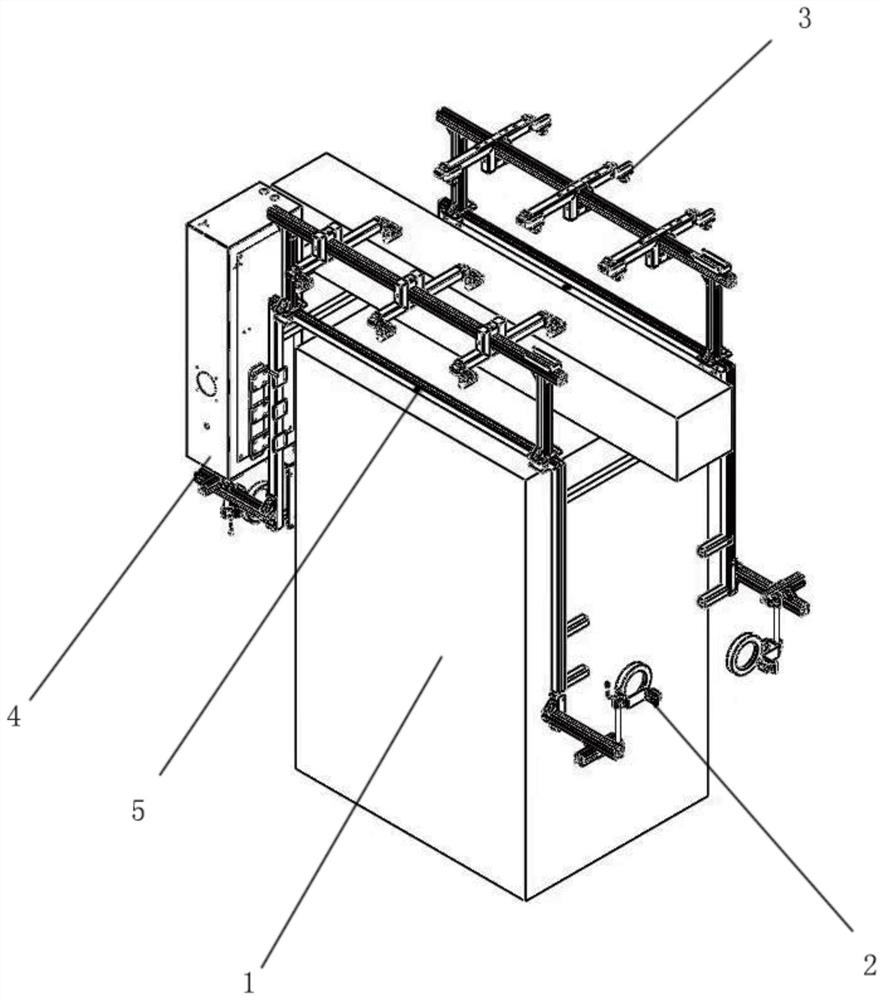

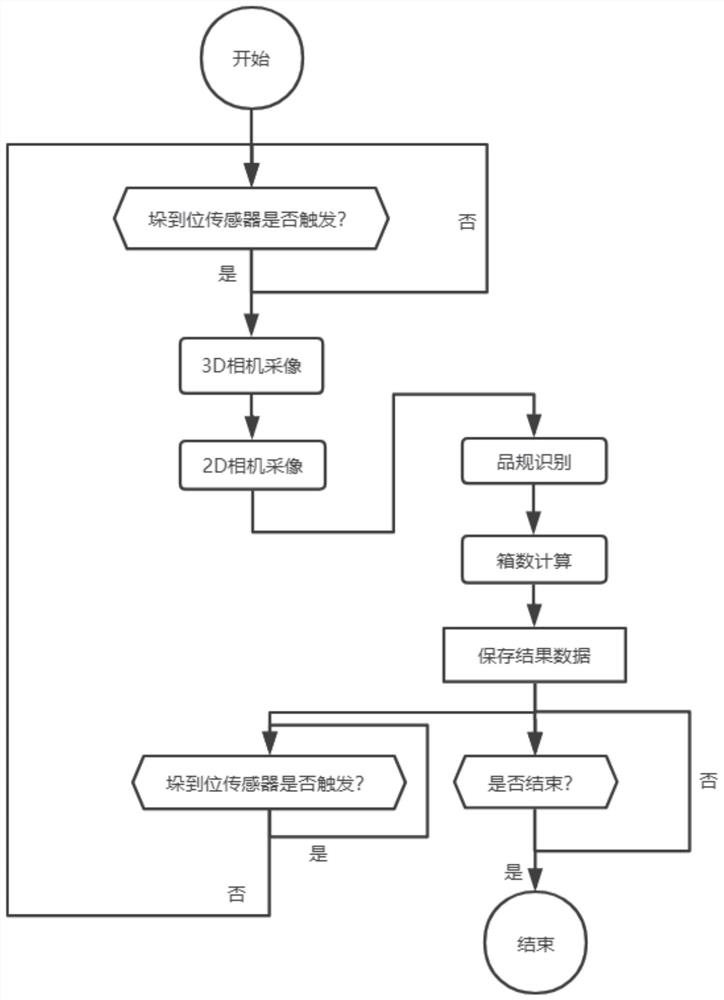

[0041] An embodiment of the present invention is figure 1 As shown in the figure, a stereoscopic library automatic inventory system for a stereoscopic library automatic inventory method is installed on the stacker platform 1. out) and a remote control terminal 4, wherein the remote control terminal 4 is connected in communication with the first image acquisition device 3, the second image acquisition device 2 and the trigger device;

[0042] Specifically, the triggering device 5 is two photoelectric sensors installed on the stacker at the front and the rear of the stacker in the direction of stacking. Make sure the stack is moved into place. On the other hand, if there is only one sensor, it is impossible to judge whether the stack is in the process of moving or has moved in place. When both sensors are sensing, it means that the stack is in place. If there i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com