A Modular Multilevel Converter Topology

A modular multi-level, inverter technology, applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., can solve the problem of large voltage fluctuation amplitude, large number of required modules, Large capacitor capacity and other problems, to achieve the effect of reducing voltage fluctuation, improving power density, and reducing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

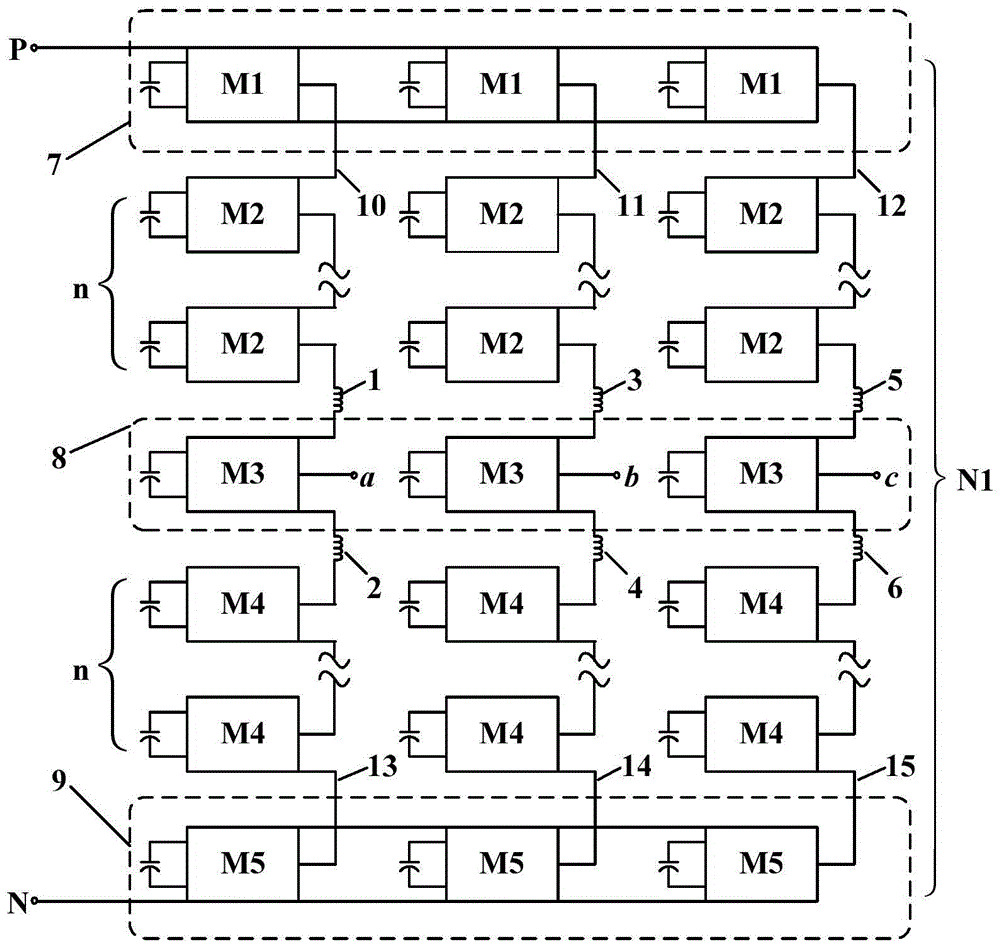

[0061] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS 1. A novel modular multilevel converter topology, which includes three top sub-modules M1, three bottom terminal modules M5, three middle sub-modules M3, 3n upper bridge arm sub-modules M2, 3n lower bridge arm sub-modules M4, first reactor 1, second reactor 2, third reactor 3, fourth reactor 4, fifth reactor 5 and sixth reactor 6, n is a positive integer;

[0062] The three top sub-modules M1 are connected in parallel to form the top module group 7; the three bottom terminal modules M5 are connected in parallel to form the bottom module group 9; the three middle sub-modules M3 form the middle module group 8; with output terminals a, b and c respectively;

[0063] A top sub-module M1 is sequentially connected in series with n upper bridge arm sub-modules M2 to form the upper bridge arm of the first phase of the converter;

[0064] A bottom terminal module M5 is sequentially connected in series with n lower bridge arm sub...

specific Embodiment approach 2

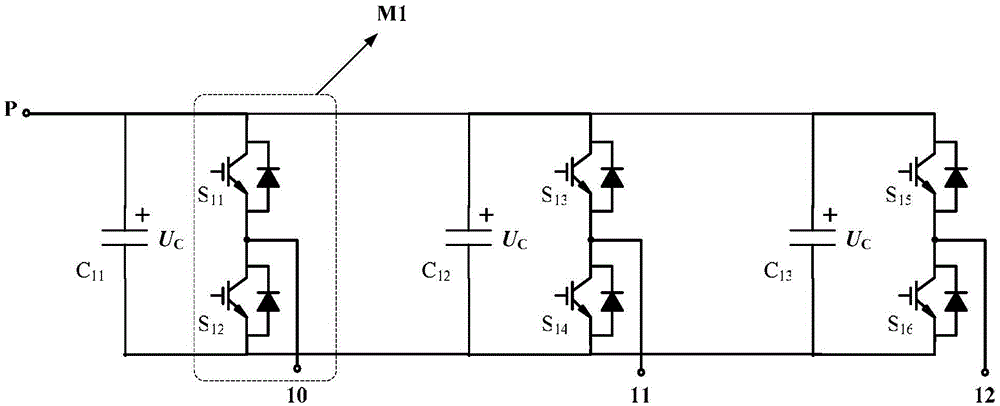

[0078] Embodiment 2. The difference between this embodiment and the new modular multilevel converter topology described in Embodiment 1 is that the specific circuit structure of the top module group 7 is: the top of the first phase circuit The sub-module M1 includes No. 1 controllable switch S11 and No. 2 controllable switch S12; the top sub-module M1 in the second phase circuit includes No. 3 controllable switch S13 and No. 4 controllable switch S14; the top sub-module M1 in the third phase circuit The sub-module M1 includes No. 5 controllable switch S15 and No. 6 controllable switch S16;

[0079] The collector of the No. 1 controllable switch S11, the collector of the No. 3 controllable switch S13 and the collector of the No. 5 controllable switch S15 are simultaneously connected to the positive pole P of the DC power supply;

[0080] The emitter of the No. 2 controllable switch S12, the emitter of the No. 4 controllable switch S14 and the emitter of the No. 6 controllable s...

specific Embodiment approach 3

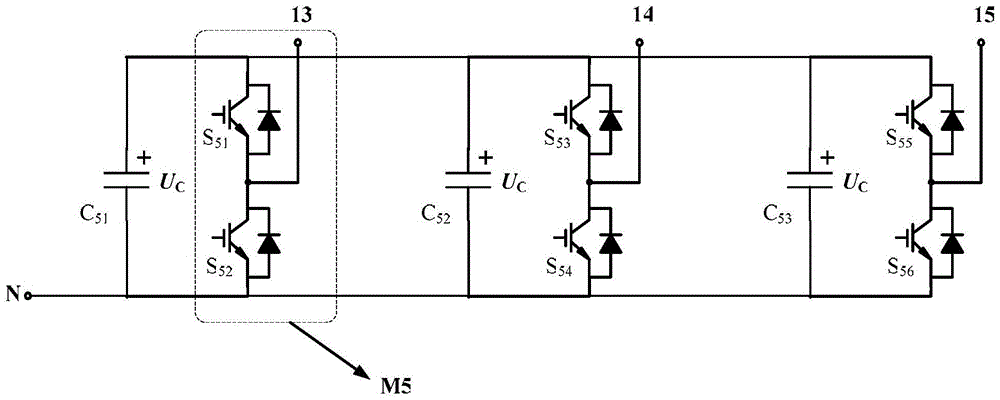

[0084] Embodiment 3. The difference between this embodiment and the new modular multilevel converter topology described in Embodiment 1 is that the specific circuit structure of the bottom module group 9 is: the first phase circuit The bottom terminal module M5 includes No. 7 controllable switch S51 and No. 8 controllable switch S52; the top sub-module M5 in the second phase circuit includes No. 9 controllable switch S53 and No. 10 controllable switch S54; The top sub-module M1 includes a No. 11 controllable switch S55 and a No. 12 controllable switch S56;

[0085] The collector of the No. 7 controllable switch S51, the collector of the No. 9 controllable switch S53 and the collector of the No. 11 controllable switch S55 are connected;

[0086] The emitter of the No. 8 controllable switch S52, the emitter of the No. 10 controllable switch S54 and the emitter of the No. 12 controllable switch S56 are connected to the negative pole N of the DC power supply at the same time;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com