A crimping riveting device for bottom steel of refrigerator and its assembling method

A technology of riveting device and pressing device, which is applied in the field of edge riveting, can solve the problems of high cost, narrow and long bonding area, high dependence on the number of employees and proficiency, and achieve the elimination of solder joints and sealing accessories, and reliable connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

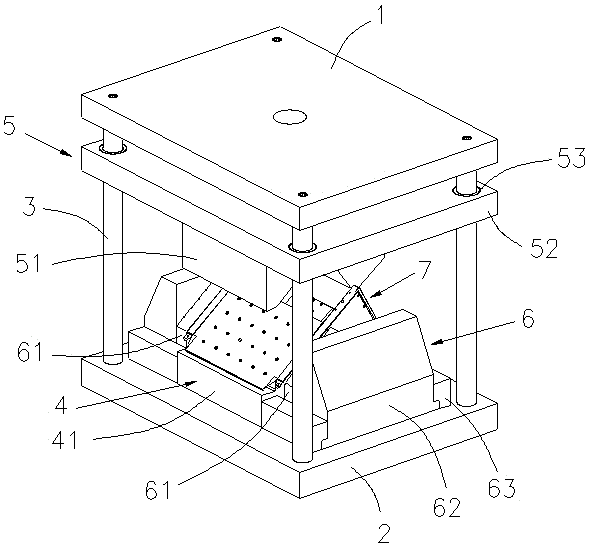

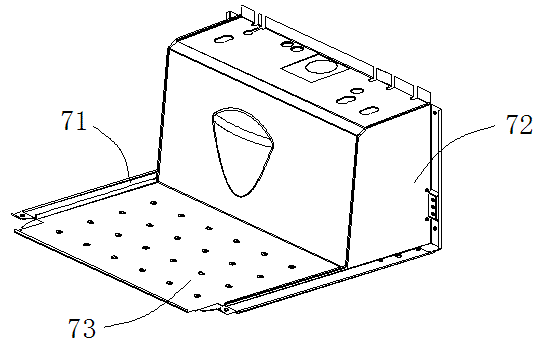

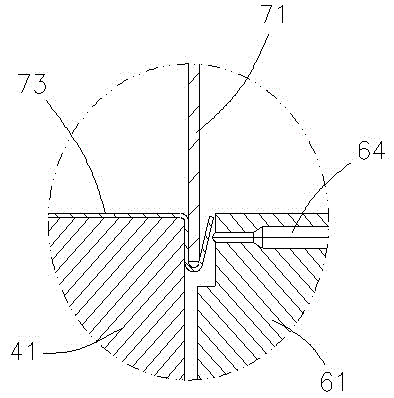

[0021] Such as figure 1 , as shown, the present invention provides a crimping riveting device for refrigerator bottom steel, comprising an upper fixing plate 1 and a lower fixing plate 2 arranged in parallel, and the upper and lower fixing plates are fixedly connected together by four guide posts 3, The refrigerator bottom steel 7 includes a left side plate 71 , a right side plate 72 and a bottom steel plate 73 . The crimping riveting device includes a supporting device 4, a pressing device 5 and a riveting device 6, and the above three devices are all arranged between the upper and lower fixing plates, wherein the lower fixing plate 2 is fixedly connected with a supporting device 4, and the supporting device A fixed mold 41 for placing the bottom steel plate 73 is provided on the top. A pressing device 5 is arranged above the supporting dev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap