Automatic demolding device and method for end flaring of automobile pipe fitting

A technology of automatic demolding and flaring die, applied in stripping devices, metal processing equipment, manufacturing tools, etc., can solve problems such as inability to take out flaring die, stuck steel pipe, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

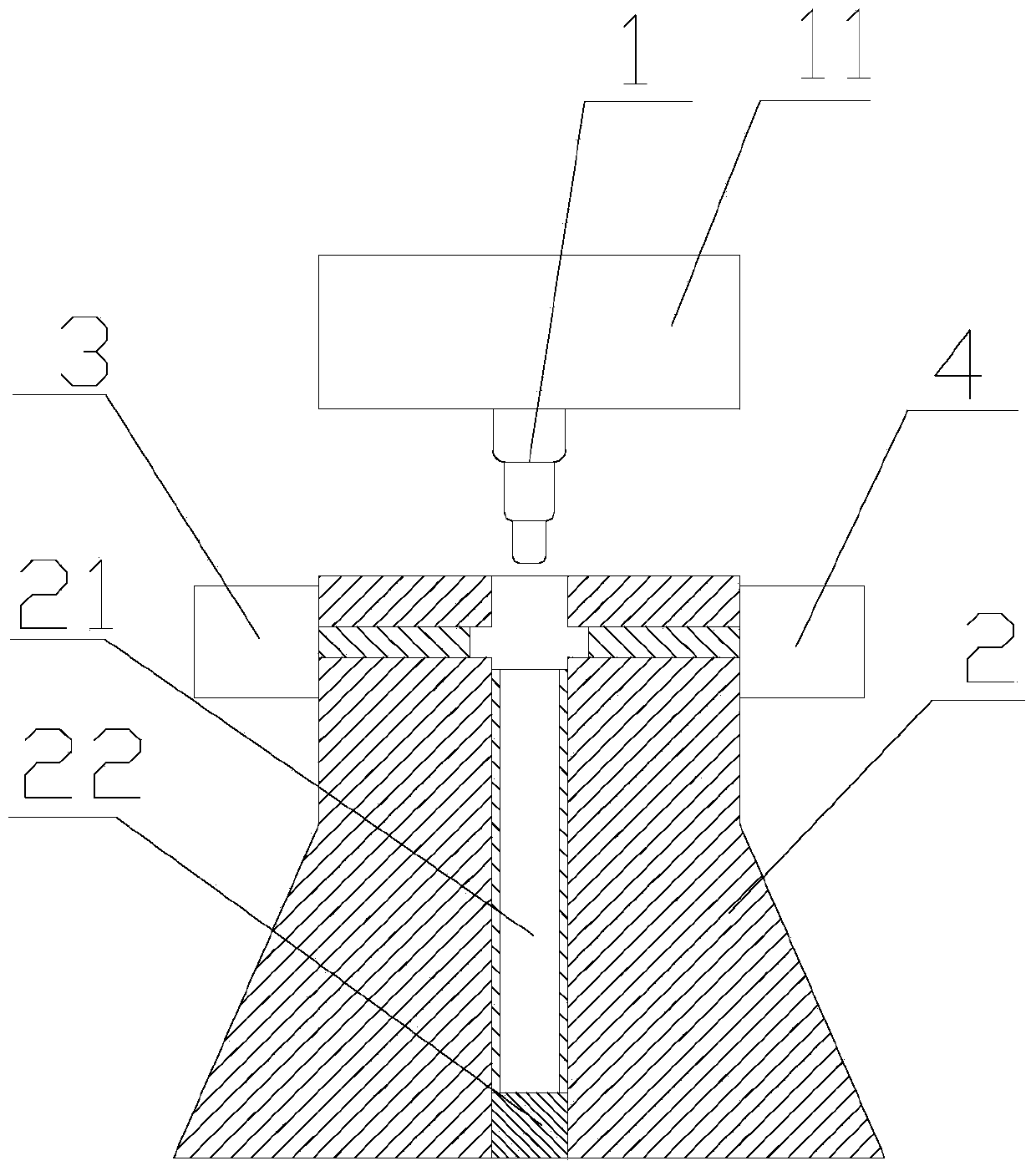

[0018] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an automatic demoulding device for the end flaring of automobile pipe fittings proposed by the present invention.

[0019] refer to figure 1 , the present invention proposes a kind of automatic demoulding device for the flaring of the end of automobile pipe fittings, comprising: an upper die 1, a lower die 2, a first cylinder 3, a second cylinder 4, a first drive mechanism and a second drive mechanism, the first The first driving mechanism and the second driving mechanism are cylinders;

[0020] The front end of the upper die 1 is provided with a flared die rod 11, the first drive mechanism is connected with the upper die 1 to drive the upper die 1 to move up and down, and the upper die 1 moves downward when expanding the mouth and drives the flared die rod 11 downward. The action expands the automobile pipe fittings, and the upper mold 1 moves upward during demoulding and drives the flared d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com