Auxiliary device of pneumatic impact wrench

An auxiliary device and impact wrench technology, which is applied in the direction of wrench, wrench, screwdriver, etc., can solve the problems of uneven locking force, loose nut lock, and loose nut, so as to avoid accidental injury, use safe and reliable, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

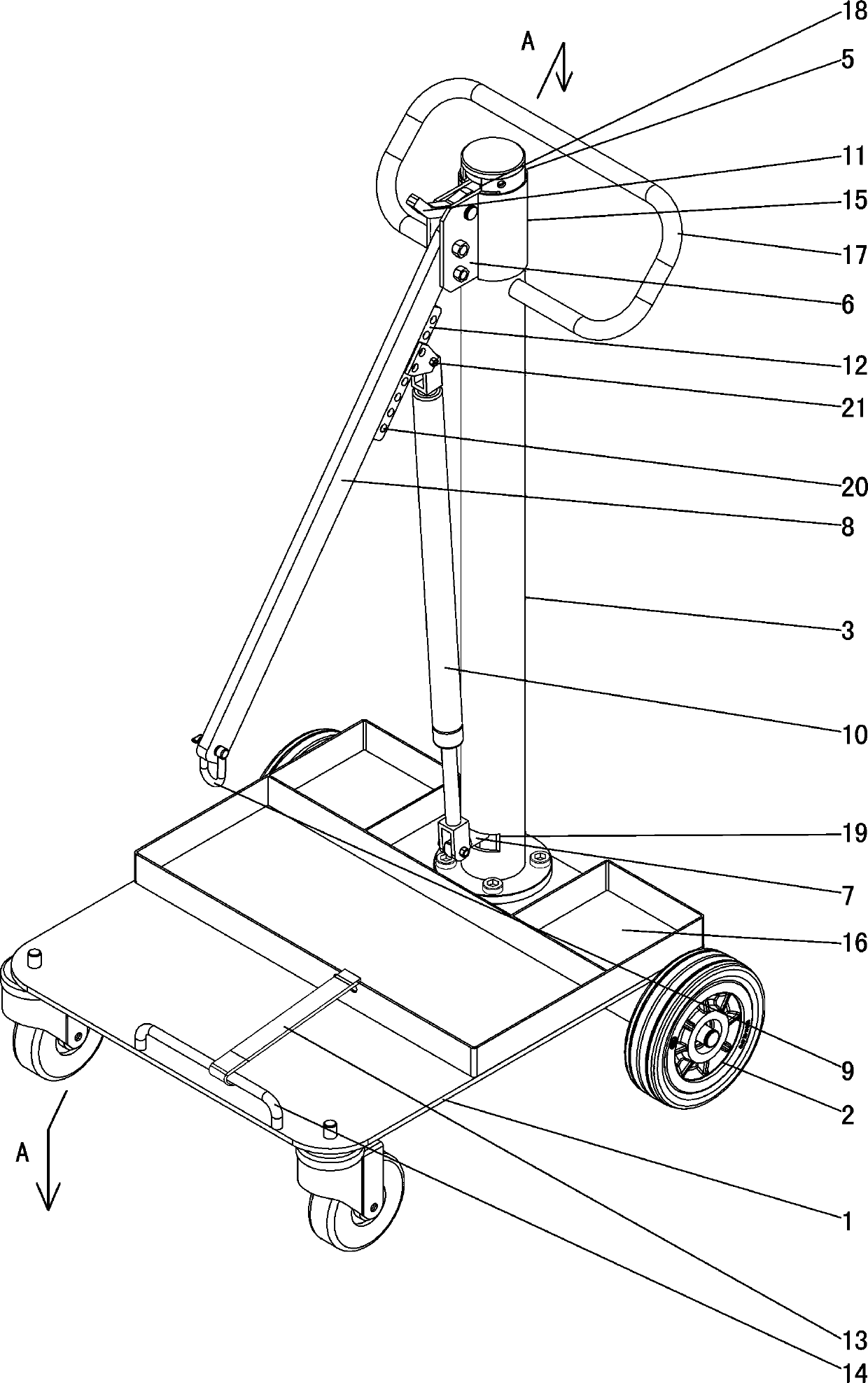

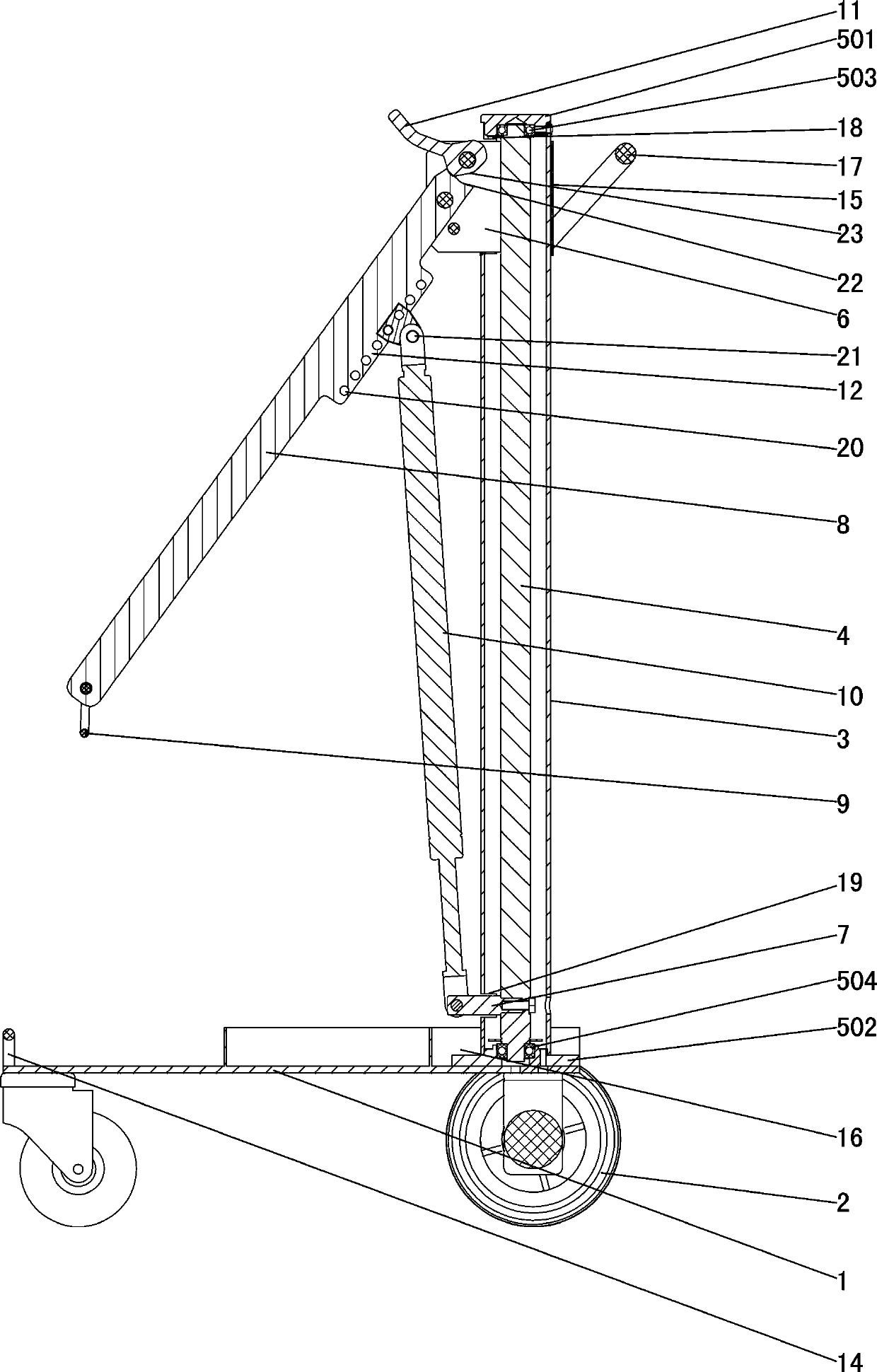

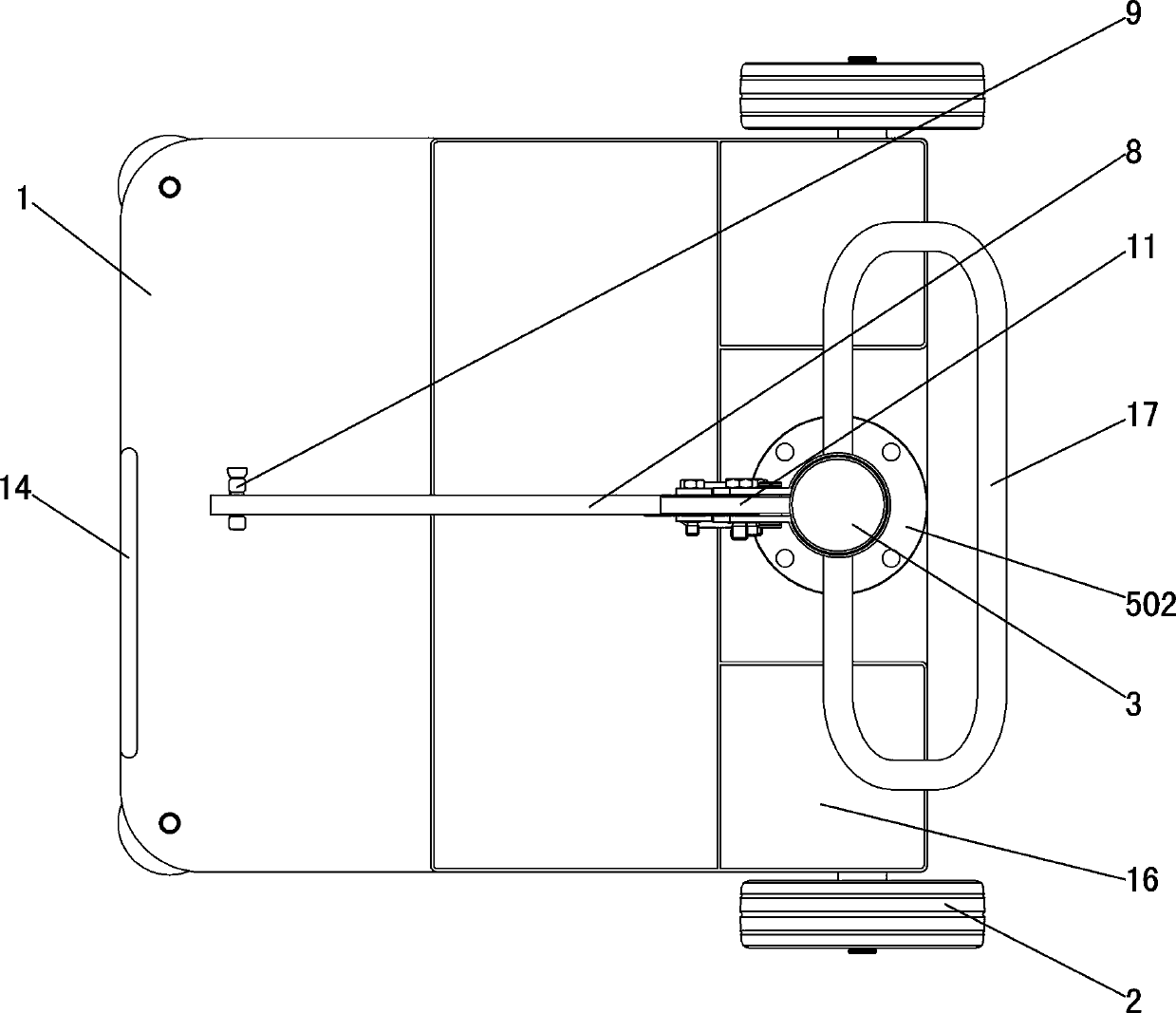

[0022] Such as figure 1 , figure 2 with image 3 As shown, this pneumatic impact wrench auxiliary device includes chassis 1, wheels 2, cylindrical column 3, rotating shaft 4, bearing assembly 5, upper limit block 6, lower limit block 7, boom 8, suspension ring 9, load telescopic rod 10. Lock handle 11, torque adjustment block 12, tightening rope 13, U-shaped iron 14, shield 15, tool tray 16 and handle 17; wheels 2 are installed under the chassis 1, and the tool tray and U-shaped iron are installed on On the chassis, one end of the binding rope is fixed on the U-shaped iron; the cylindrical column 3 is installed vertically on the chassis 1; the handle 17 is installed on the upper end of the cylindrical column 3; In the column 3; the upper end of the cylindrical column 3 is provided with an upper limit port 18, and the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com