Automatic water boiling cooking processing equipment

A processing equipment and boiling technology, which is applied in the field of automatic boiling processing equipment, can solve the problems of heavy workload, inconvenient boiling cycle curing operation, and unfavorable use of operators when feeding and discharging materials, and achieves high practical performance. , The effect of convenient control and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

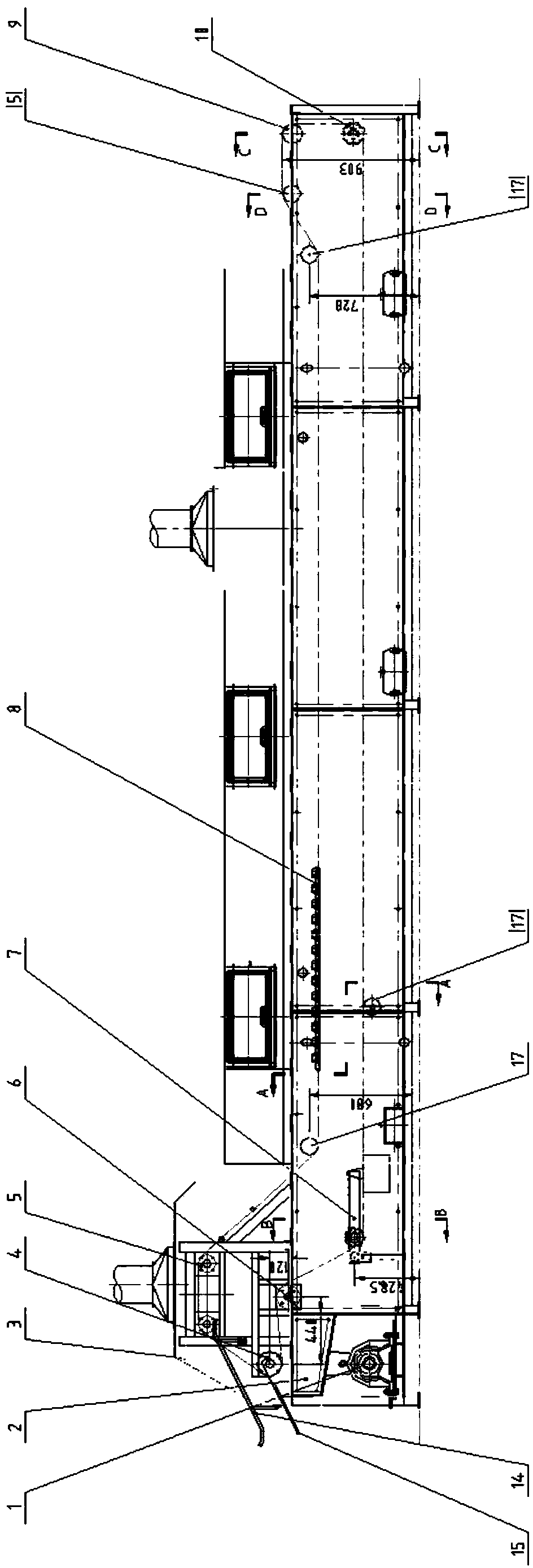

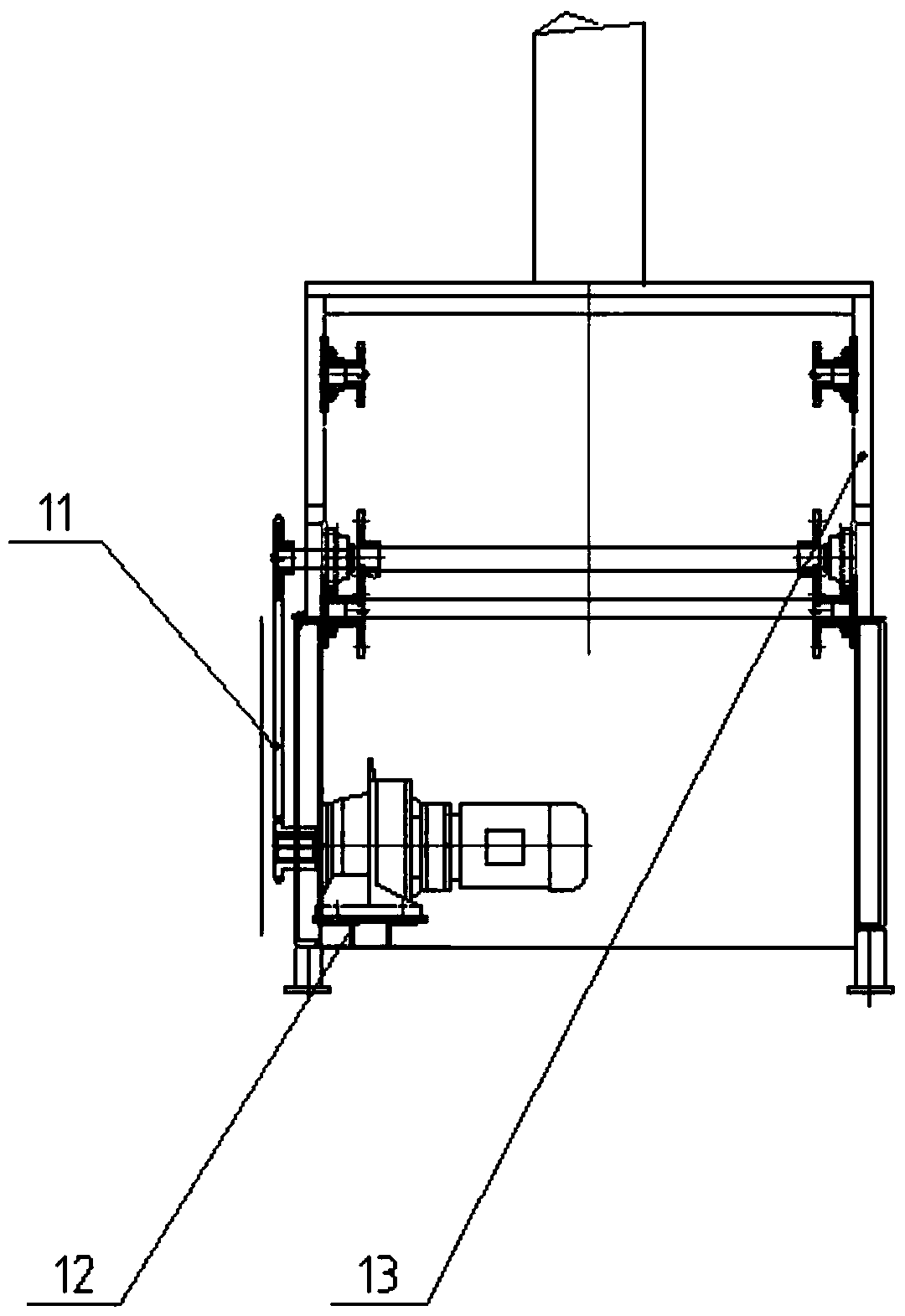

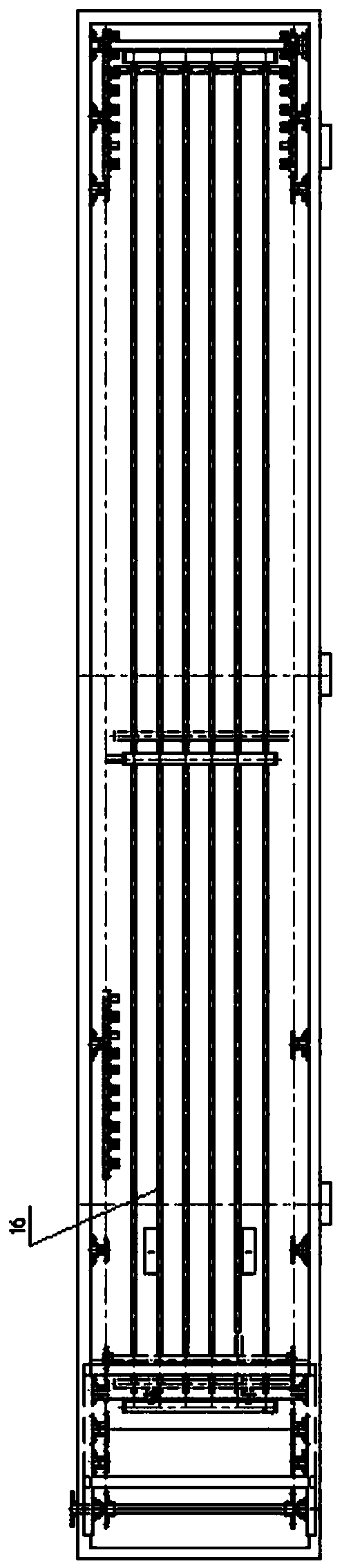

[0024] refer to Figure 1-7 , a kind of automatic boiled system processing equipment is proposed in the present embodiment, comprises casing 2, is provided with corner sprocket group 6, does not have seat support sprocket group 17, tail lower sprocket group 9 and The upper chain wheel group 10 at the tail, the corner chain wheel group 6, the supporting chain wheel group 17 without a seat, the lower chain wheel group 9 at the tail part and the upper chain wheel group 10 at the tail part are connected with the same conveying chain 8, and the two parts of the casing 2 A chain track assembly 18 is installed on the side inner wall, and the chain track assembly 18 is slidingly connected with the conveying chain 8. A tensioning device 7 is arranged in the box body 2, and the tensioning device 7 cooperates with the chain 8. One side inner wall of the box body 2 The gear motor support 12 is fixedly installed on the gear motor support 12, and the gear motor 1 is fixedly installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com