Hockey stick preform and hockey stick manufacturing method

A hockey stick and rod preforming technology, which is applied in the field of sporting goods, can solve the problems of low reusability, achieve high reusability, good elasticity, and reduce the probability of air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

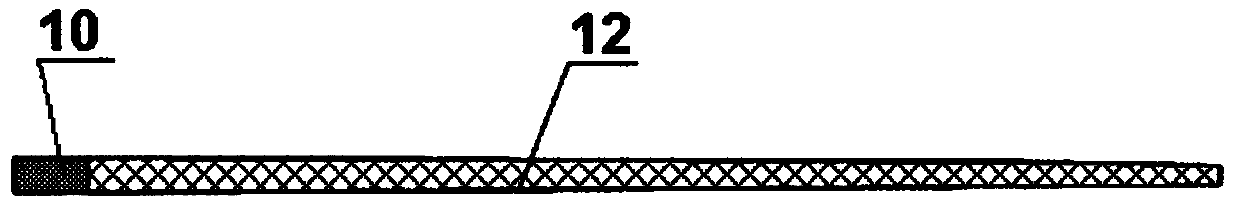

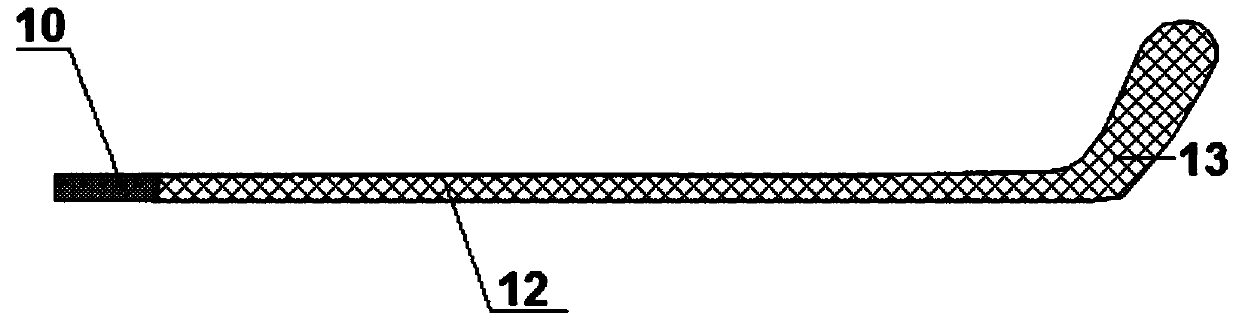

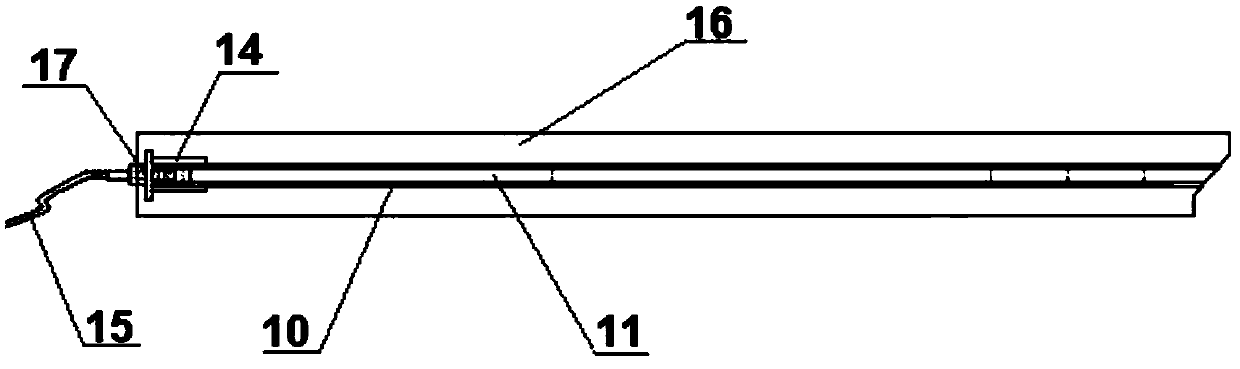

[0046] like figure 1 , image 3 The embodiment shown is a hockey stick preform, comprising a rubber film tube 10 with a rectangular cross-section and an aluminum alloy support rod 11 arranged in the rubber film tube, the cross-sectional width of the rubber film tube is from the open end to the closed end. The ends of the rubber membrane tube are gradually reduced. One end of the rubber membrane tube is a closed end for connecting with the bat, and the other end of the rubber membrane tube is an open end. The open end is provided with a rubber membrane tube joint 17 for connecting to the wind pressure. The cross-sectional width of the metal support rod matches the cross-sectional width of the rubber membrane tube.

[0047] like Figure 4 , Figure 5 , Image 6 As shown, the rubber membrane pipe joint includes a ventilation pipe 1 with a ventila...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com