Workpiece deformation screening automatic conveying arrangement device

An automatic conveying and arranging device technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of inability to effectively improve efficiency and accuracy, heavy labor, and low work efficiency, and achieve rapid screening, improve efficiency, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

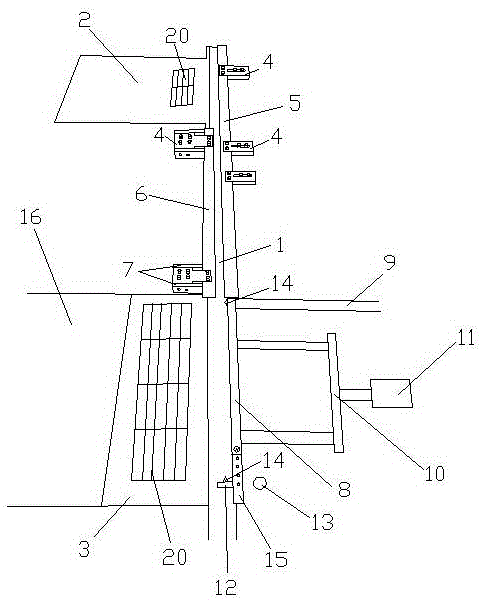

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] Such as figure 1 As shown, an automatic conveying and arranging device for deformation screening of workpieces, the two ends of the linear conveyor belt 1 are respectively provided with a feeding table 2 and a discharge table 3; one side of the linear conveyor belt 1 is provided with a fixed guide plate 5 through a clamp block 4; the linear conveyor belt 1 The other side is provided with a movable baffle 6, and the movable baffle 6 is moved and connected with the guide rail 7 through the clamp block 4; the distance between the movable baffle 6 and the fixed guide plate 5 can be adjusted according to the width of different iron core workpieces 20, if If the iron core workpiece 20 is transversely bent, it cannot pass through. At this time, the defective workpieces can be screened out. The front end of the discharge workbench 3 is provided with an arrangement mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com