A parallel intake type rear bypass ejector in the adjustable mechanism of a variable cycle engine

A variable cycle engine, air intake technology, applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problems of valve body actuation time lag, large mixing loss, obstruction of airflow, etc., to reduce processing difficulty, reduce Detrimental influence, effect of reducing the accumulation of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

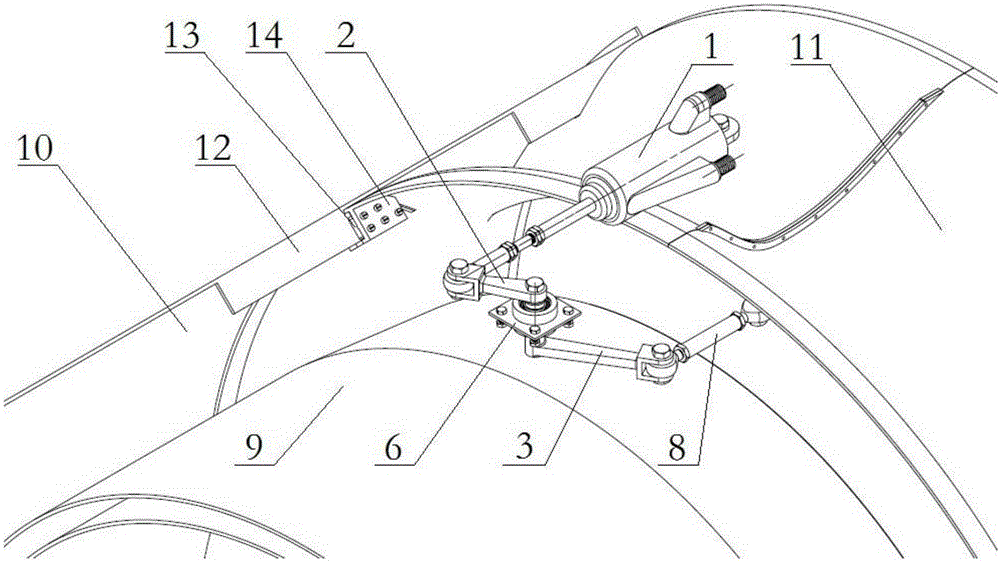

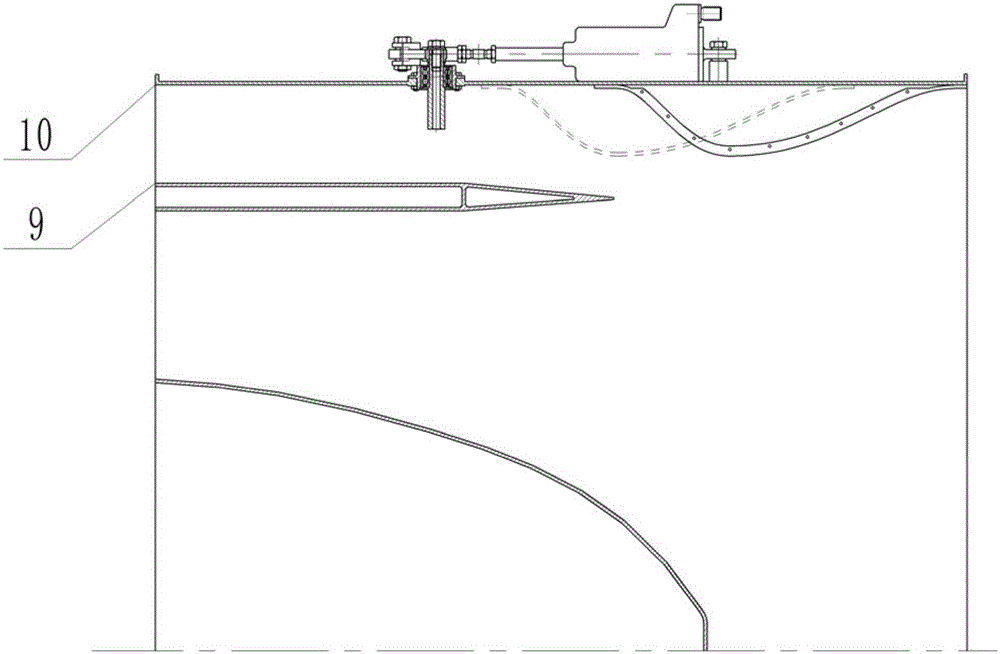

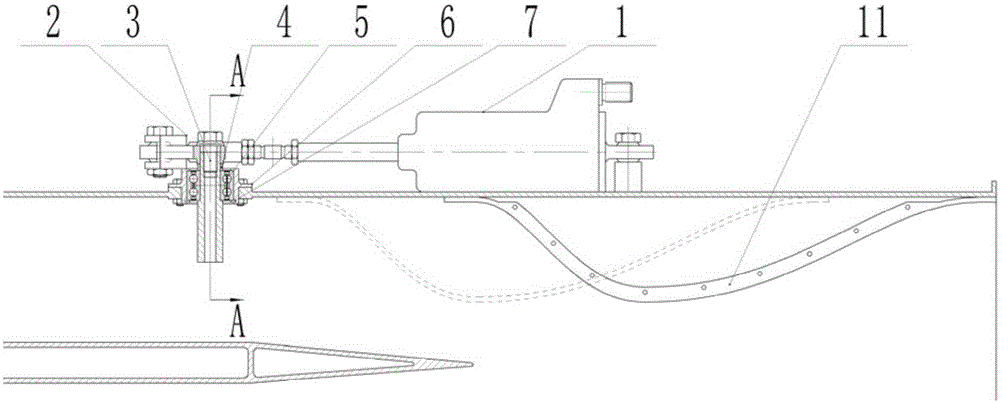

[0061] The present invention is a parallel intake type rear duct ejector in the variable cycle engine adjustable mechanism, and its specific implementation is as follows:

[0062] like figure 1 , Figure 2a , Figure 2b Figure 3a , Figure 3b , Figure 4a , Figure 4b , Figure 5a , Figure 5b , Figure 6a and Figure 6b As shown, the parallel intake type rear duct ejector in the adjustable mechanism of this variable cycle engine is located between the low-pressure turbine outlet of the engine and the afterburner inlet, at the mixing place of the inner and outer duct airflows. The rear duct ejector of the present invention consists of an actuator 1, a connecting arm 2, a rotating shaft 3, a sleeve 4, a bearing 5, a bearing seat 6, a retaining ring 7, a connecting rod 8, an inner casing 9, and an outer casing 10 , valve body 11, slide bar 12, friction block 13, friction block installation platform 14 and form. The rear joint bearing 1-1 of the actuator 1 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com