Method and device for finishing workpieces

A technology for finishing and workpieces, applied in the field of non-rotationally symmetrical components, it can solve the problems of a lot of finishing time, inaccurate self-guided support of finishing tools, and inability to remove, and achieves the effect of preventing wet grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

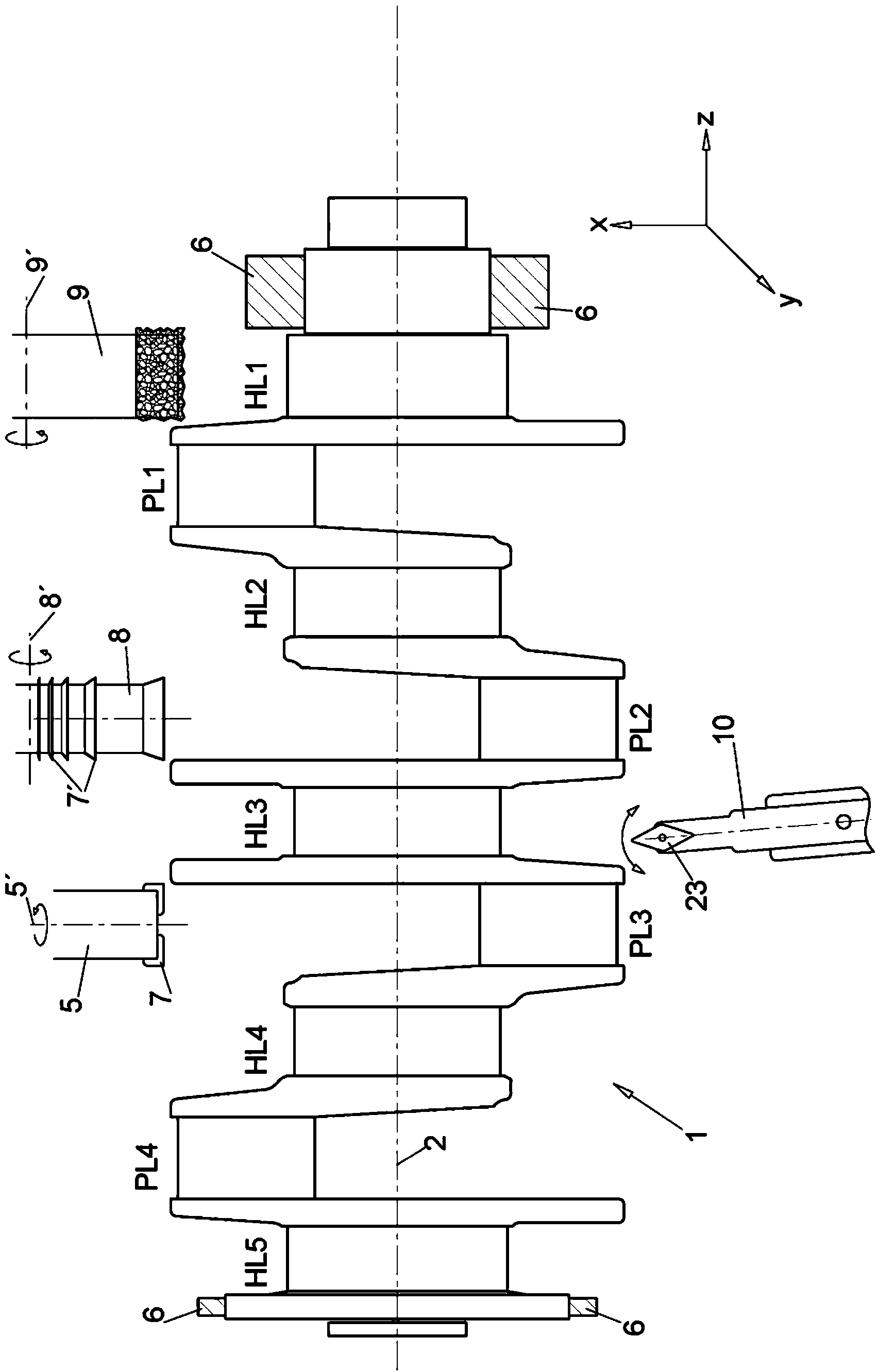

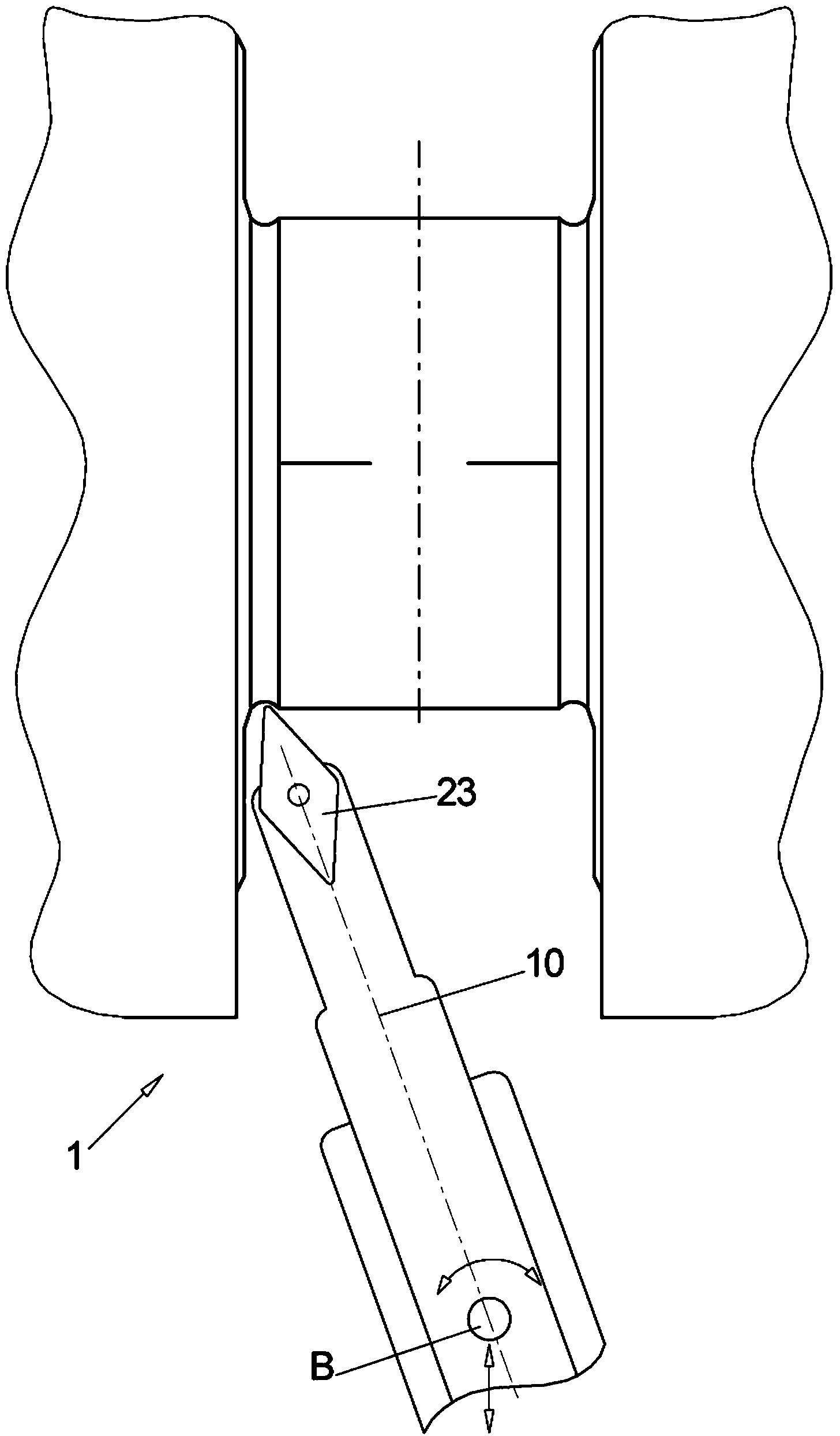

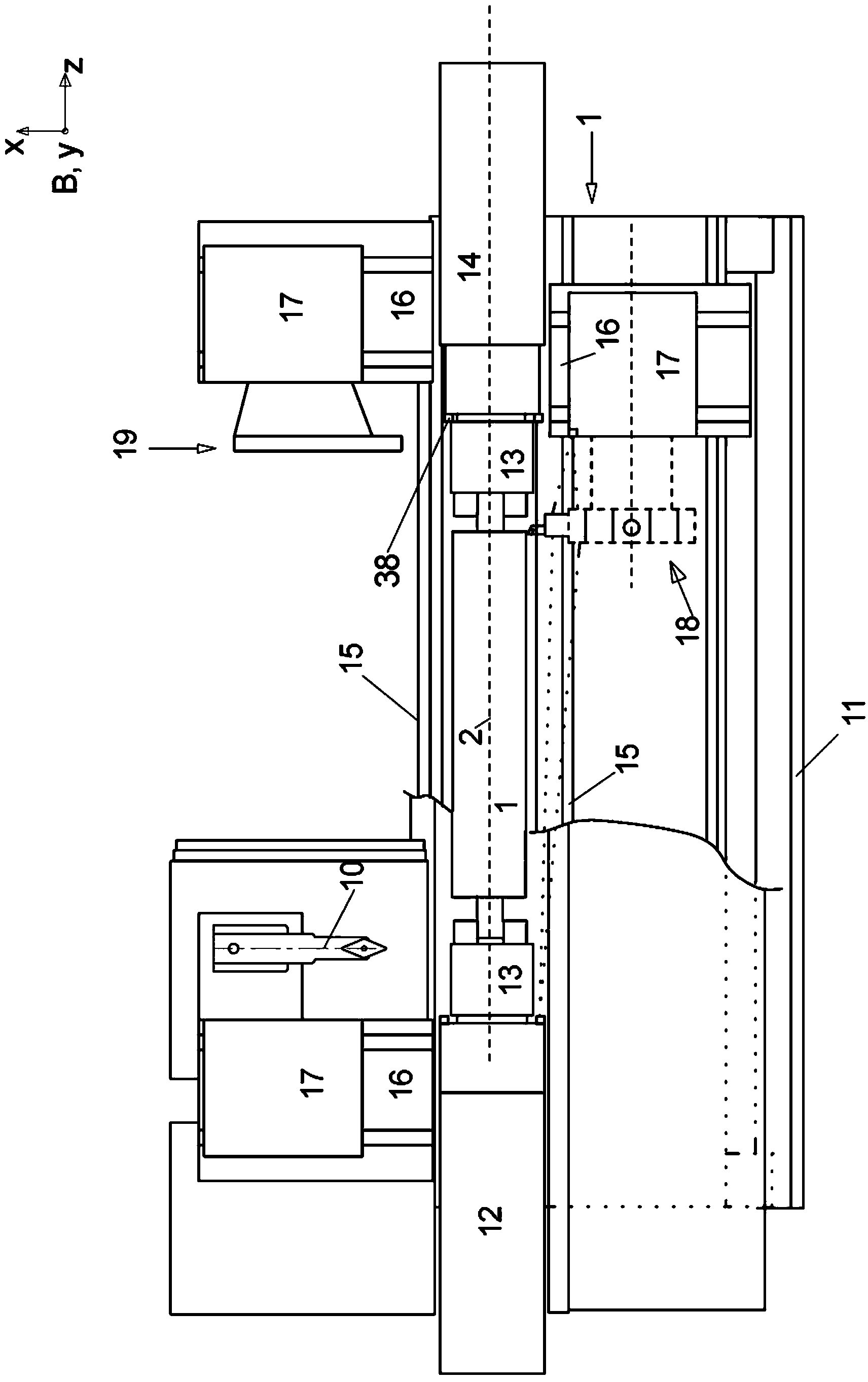

[0103] Figure 1a Illustrated is a side view of a typical crankshaft 1 of a four-cylinder combustion engine, wherein there are thus four eccentric elevator-or rod bearings PL1 to PL4 and a total of 5 main bearings HL1 to HL5 arranged adjacent thereto, wherein The main bearings are arranged on the subsequent axis of rotation (Z axis of the crankshaft), so by radial clamping by means of the jaws 6 at the flange 4 at one end and the pinion 3 at the other end of the crankshaft 1, The crankshaft 1 is clamped in a lathe (not described in more detail) on said rotational axis, which is also designated as rotational axis 2 in the illustration of FIG. 1 .

[0104] In particular, the invention relates to the machining of the enclosing surfaces of the bearing, and thus the main bearing, as well as the rod bearing including adjacent sides (so-called mirror surfaces).

[0105] Above and below crankshaft 1, the machine tool is shown in an exemplary manner from top left to right:

[0106] - ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com