Washing machine

A washing machine and laundry technology, which can be applied to other washing machines, washing devices, cabinets/cases/drawer parts, etc., and can solve the problems of increased water volume, wrong display, and easy intrusion of foreign objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

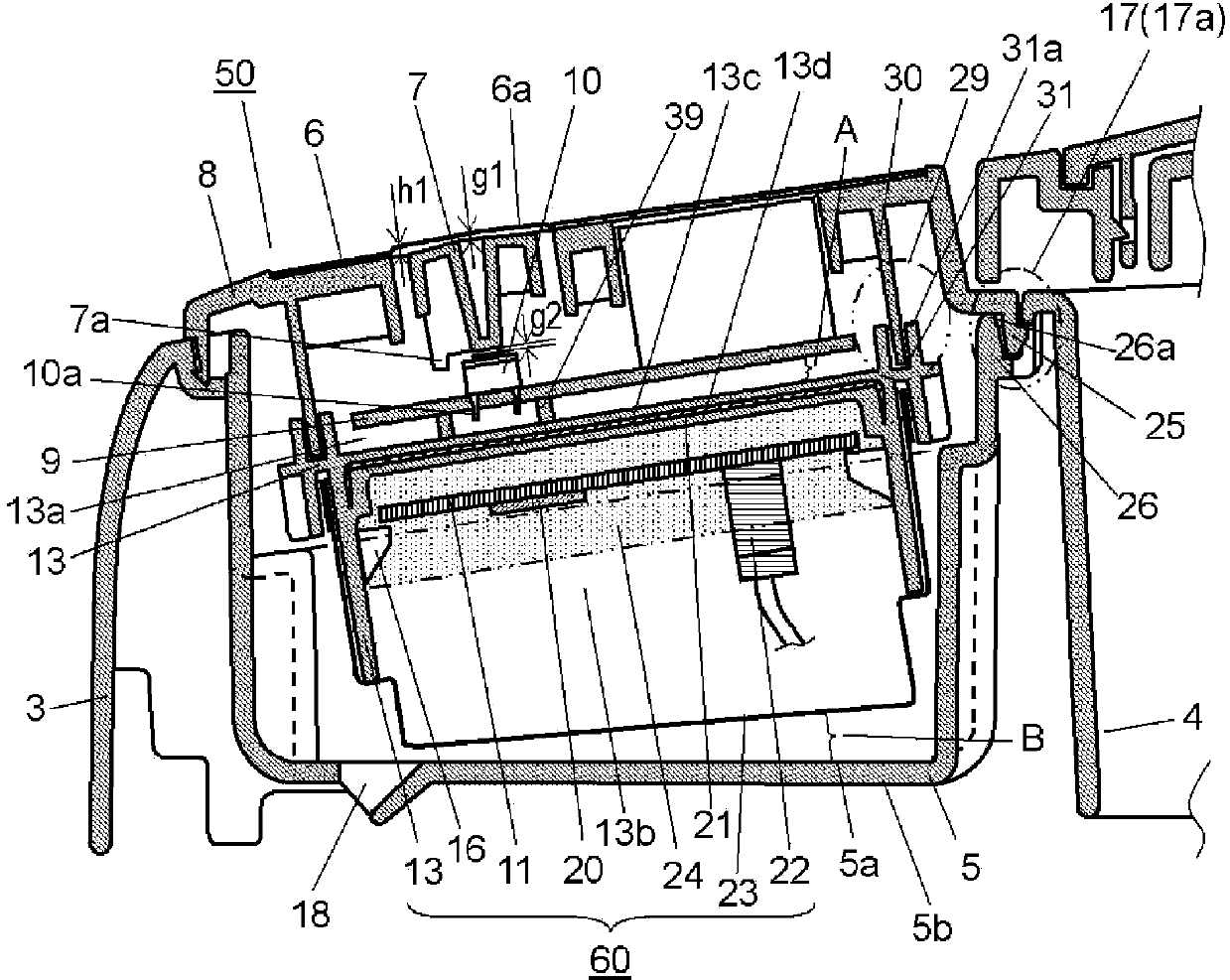

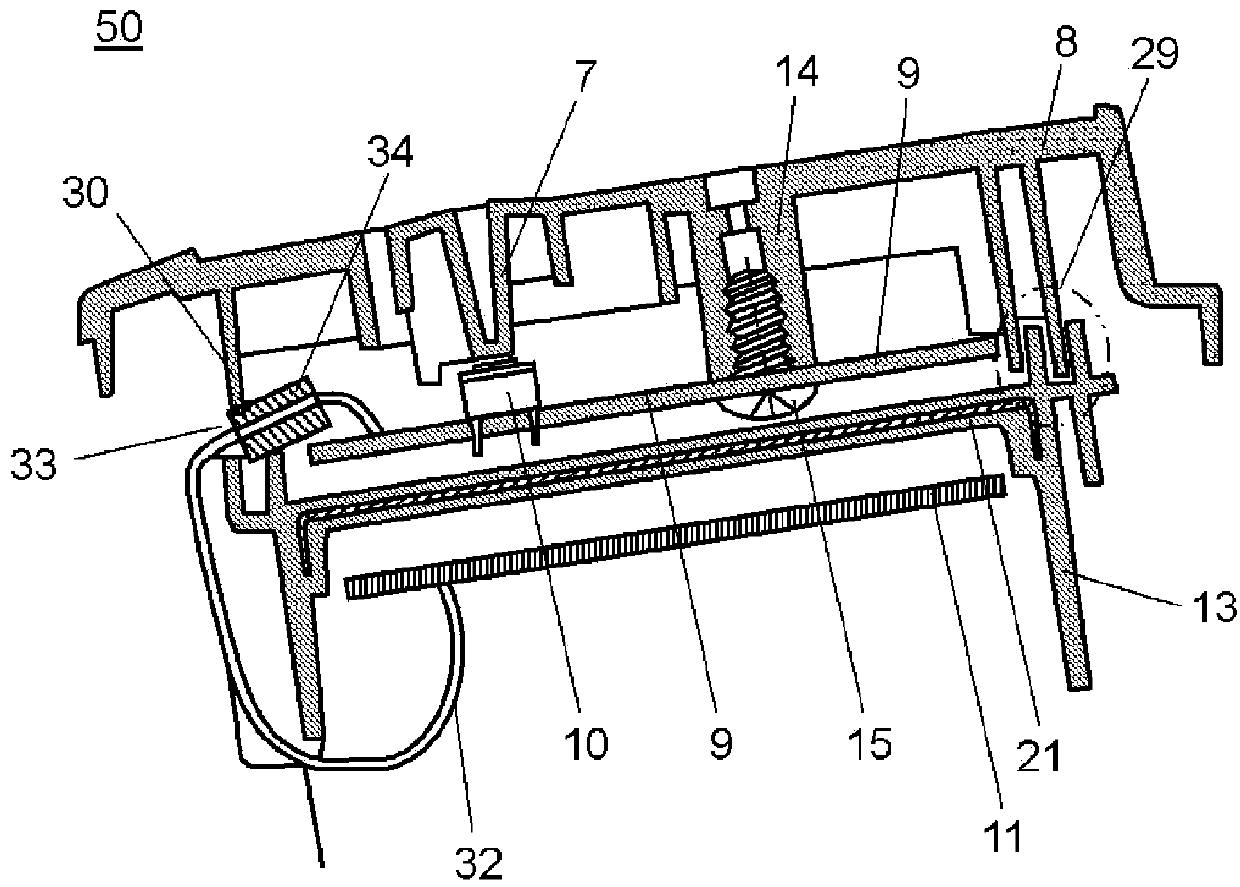

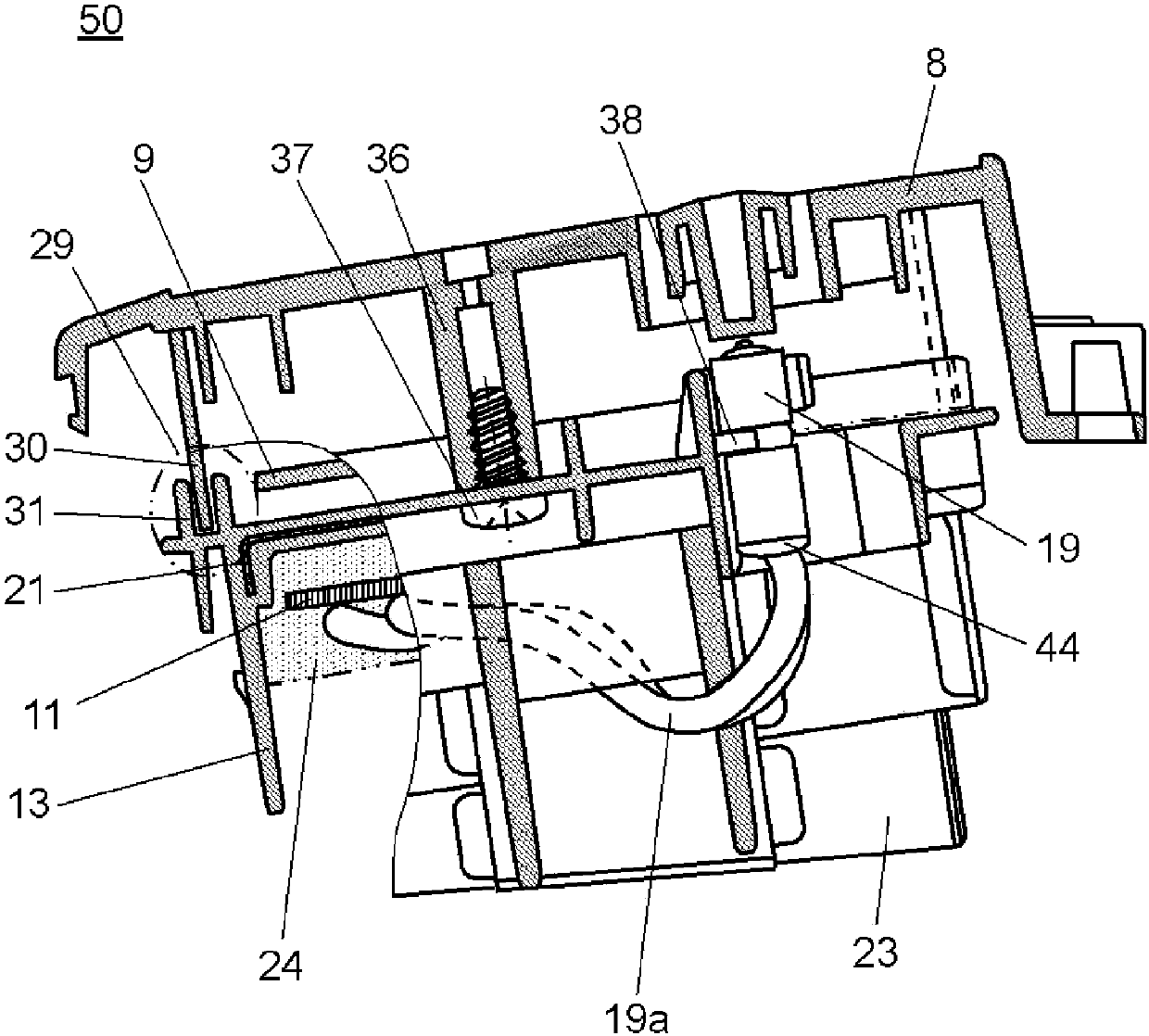

[0040] Below, use Figure 1 to Figure 6The power supply unit, the operating device, and the washing machine provided with the power supply unit and the operating device in Embodiment 1 of the present invention will be specifically described. In addition, below, a vertical washing machine will be described as an example.

[0041] figure 1 It is a sectional view of main parts around the power supply unit and the operation unit of the washing machine in Embodiment 1 of the present invention. figure 2 It is a sectional view of main parts of the washing machine. image 3 It is a sectional view of main parts of the washing machine. Figure 4 It is a sectional view of main parts of the washing machine. Figure 5 It is an upper sectional view of the washing machine. Figure 6 It is a sectional view of main parts of the washing machine.

[0042] like Figure 1 to Figure 6 As shown, the washing machine of this embodiment at least includes: a washing and dehydrating tank 1 (here...

Embodiment approach 2

[0135] Below, use Figure 8 A power supply unit, an operating device, and a washing machine including the power supply unit and the operating device in Embodiment 2 of the present invention will be described. In addition, below, similarly to Embodiment 1, a vertical washing machine will be described as an example.

[0136] Figure 8 It is a cross-sectional view of main parts around the power supply unit and the operation unit of the washing machine in Embodiment 2 of the present invention.

[0137] That is to say, the difference between the washing machine of this embodiment and Embodiment 1 is that, instead of the power supply device constituting a part of the operation device, the boat-shaped protective case formed by insert-molding the first non-combustible cover is replaced by the boat-shaped protective case and the power supply. A non-combustible member is provided between the substrates. In addition, description of the same structural elements, functions, etc. as thos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com