Lubricant dispenser

A lubricant and distributor technology, applied in the direction of engine lubrication, engine components, mechanical equipment, etc., can solve problems such as increasing current consumption, and achieve the effect of reducing current consumption, improving energy efficiency, and reducing battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

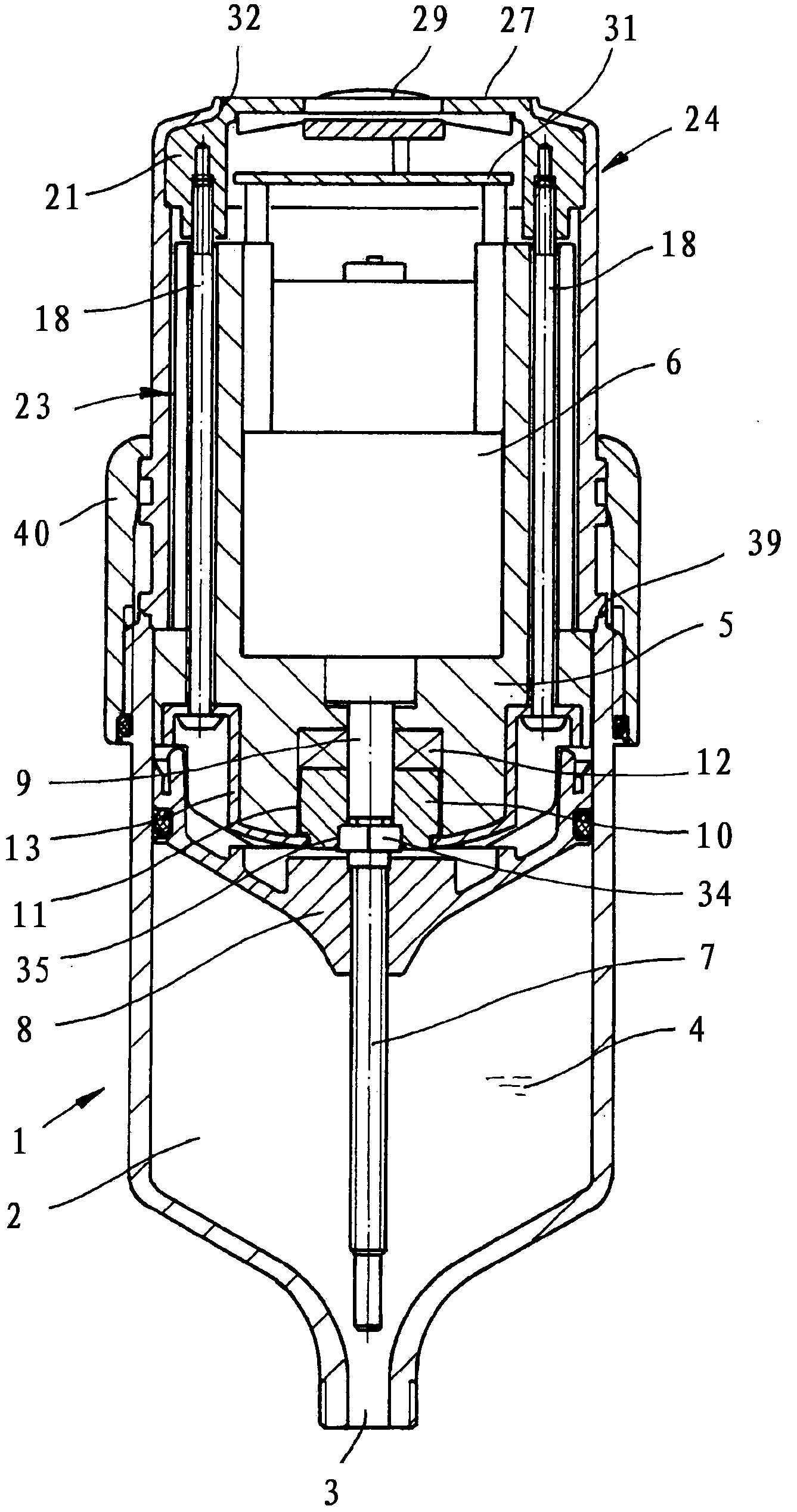

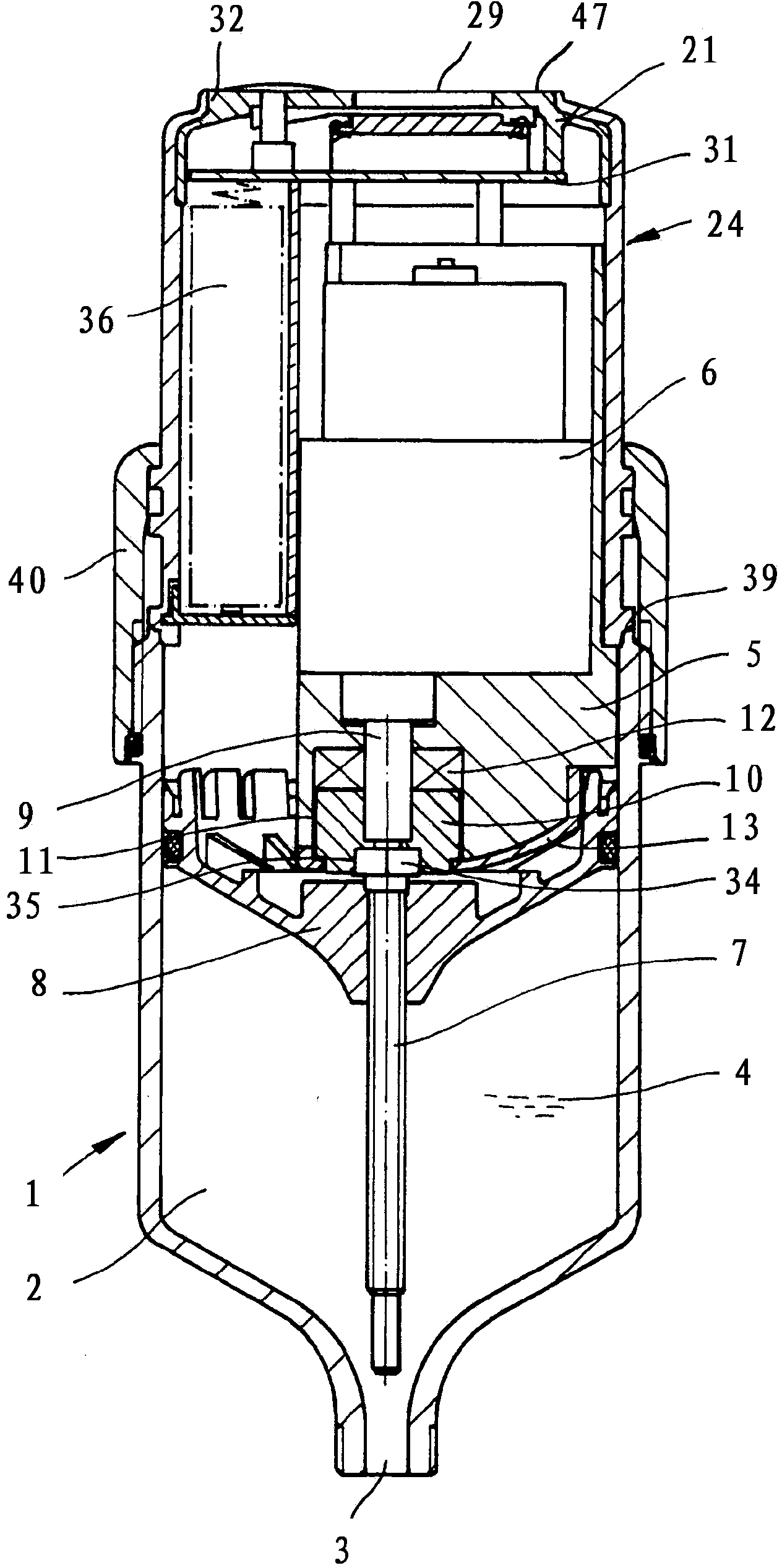

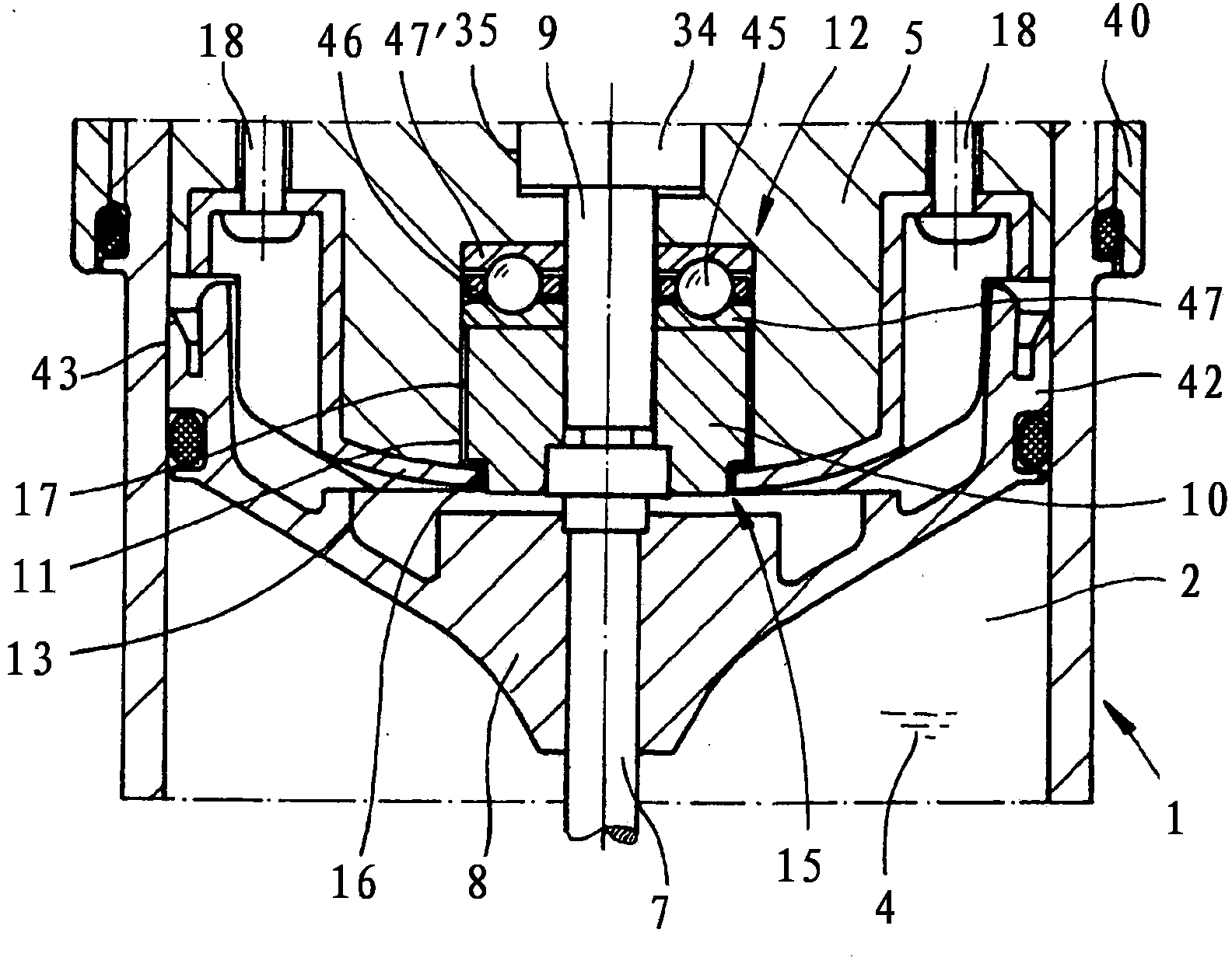

[0023] The basic structure of the lubricant dispenser shown in the accompanying drawings includes: a lubricant cartridge 1, which has a lubricant storage chamber 2 provided with a lubricant 4 outlet 3; a bracket that is detachably connected to the lubricant cartridge 1 5. The bracket accommodates a battery-powered motor 6 for driving the screw 7; a piston 8 connected with the screw 7 for pressing out lubricant. The motor 6 , which in the lubricant distributor shown here is an electric gear motor, has an output shaft 9 which is connected to the screw 7 by means of an adapter 10 . The adapter 10 is mounted rotatably in a receiving space 11 of the holder 5 which is open towards the lubricant cartridge 1 . A rolling bearing 12 is provided as a bearing for the adapter 10 , which is arranged between the carrier 5 and the adapter 10 . The adapter 10 is secured against falling out of the receiving space 11 in the axial direction by means of restraint means 13 secured to the bracket 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com