Horizontal tuning frame type eddy current damper

An eddy current damper and eddy current damping technology, which is applied in the direction of protective buildings/shelters, building components, and earthquake resistance, can solve problems such as not completely solved, achieve good results, improve energy consumption efficiency, and achieve good results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

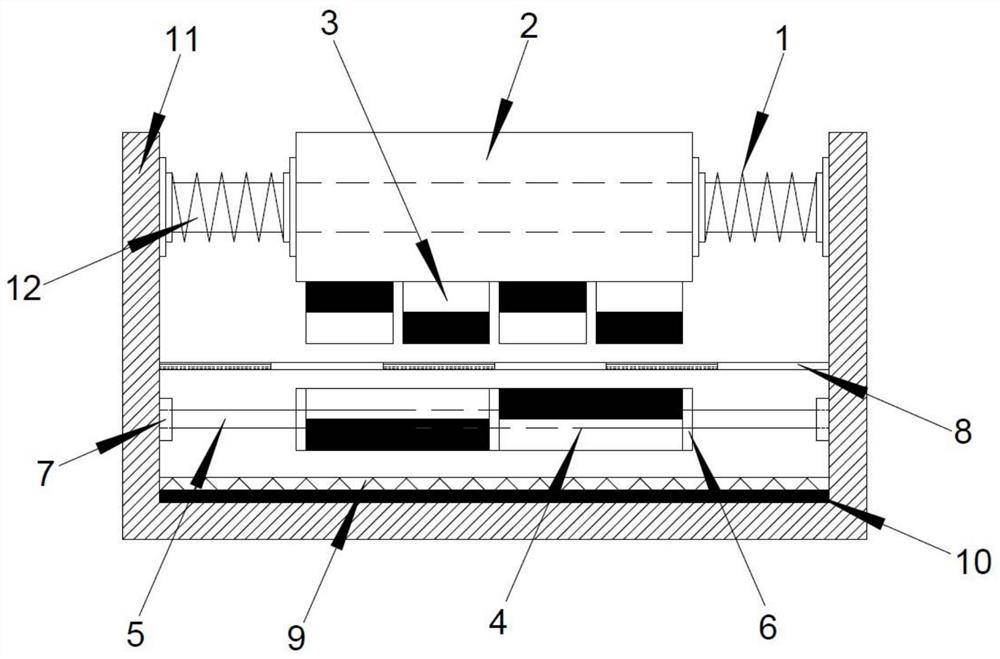

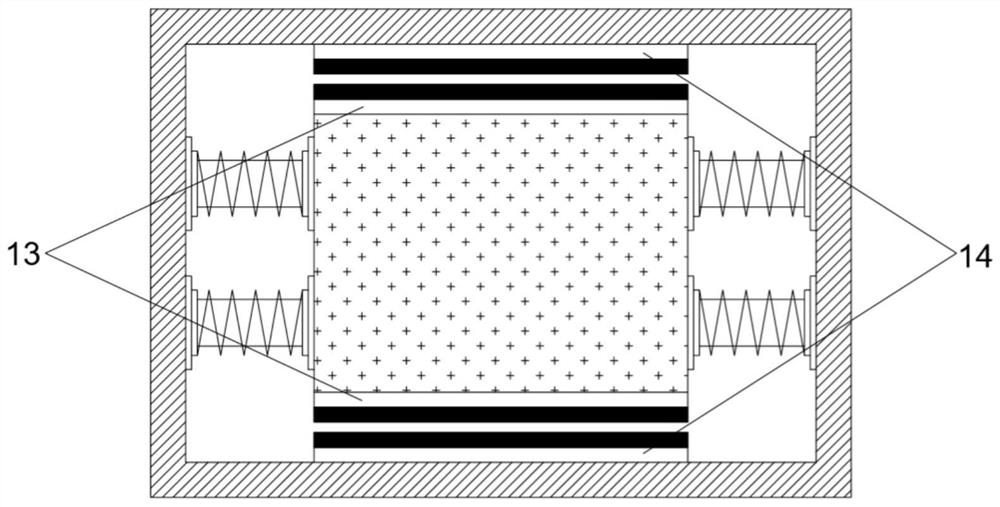

[0038] like figure 1 and figure 2 Shown is a negative stiffness level tuned mass magnetic field modulation type eddy current damper, the damper includes a support system, a spring-mass system, an eddy current damping system and a negative stiffness system; the support system includes an outer frame (11) and a guide rod (12), the guide rod (12) is horizontally arranged and its two ends are fixedly mounted on the outer frame (11); the spring mass system includes a spring (1) and a counterweight (2), the The spring (1) is sleeved on the guide rod (12), the fixed end of the spring (1) is consolidated with the outer frame (11), and the free end is consolidated with the counterweight (2); the counterweight (2) set on the guide rod (12) and can carry out horizontal linear motion along it; the eddy current damping system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com