Charging pump for nuclear power station

A technology for nuclear power plants and pump heads, which is applied to components of pumping devices for elastic fluids, pumps and pumps for special fluids, etc., can solve the problems of inconvenient processing and non-destructive inspection, and inconvenient sand cleaning and grinding in inner flow channels. , increase the risk of radioactive substances, etc., to achieve the effect of convenient non-destructive testing, convenient testing, and reducing the possibility of adhering to the radiation medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

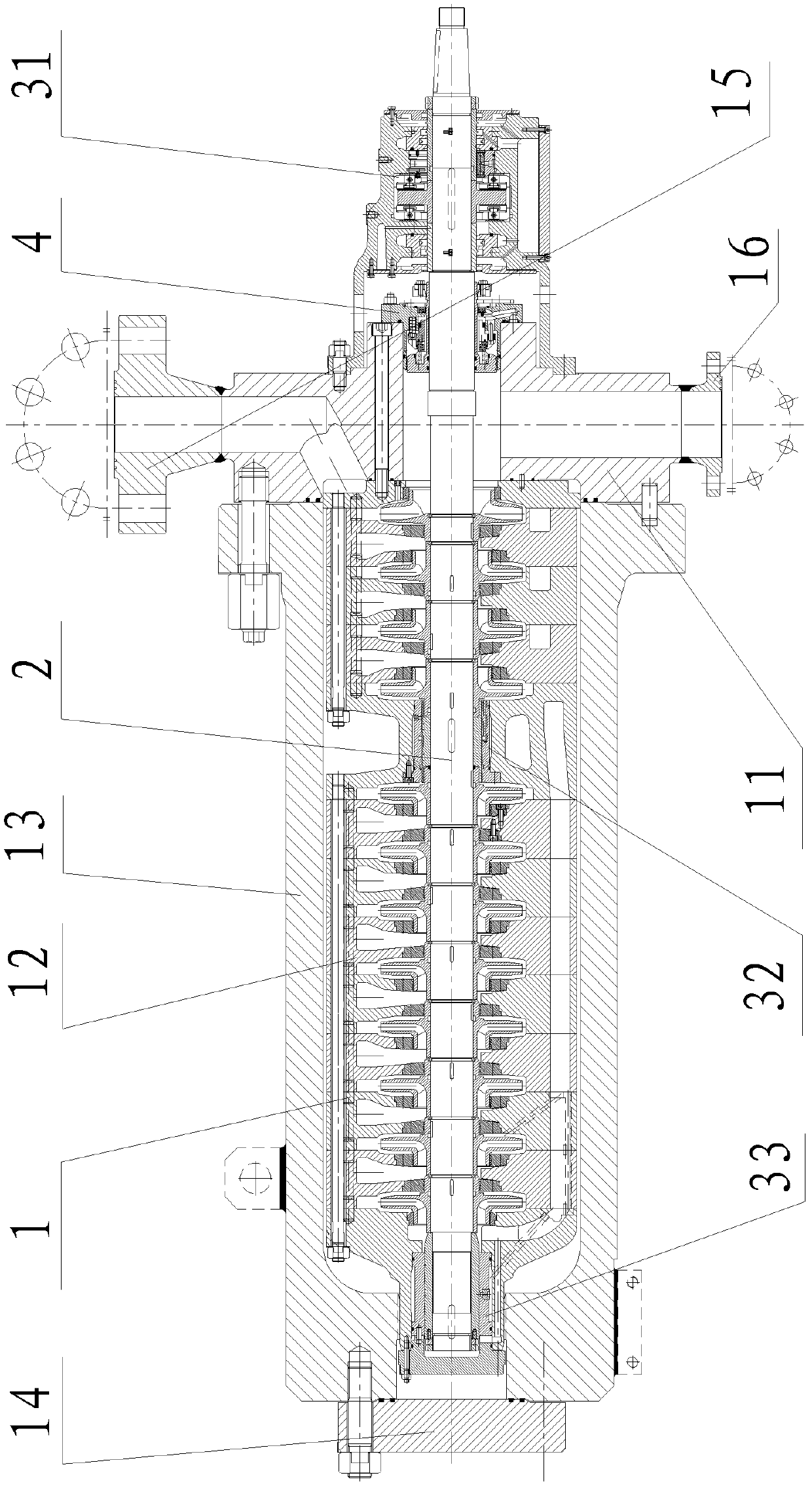

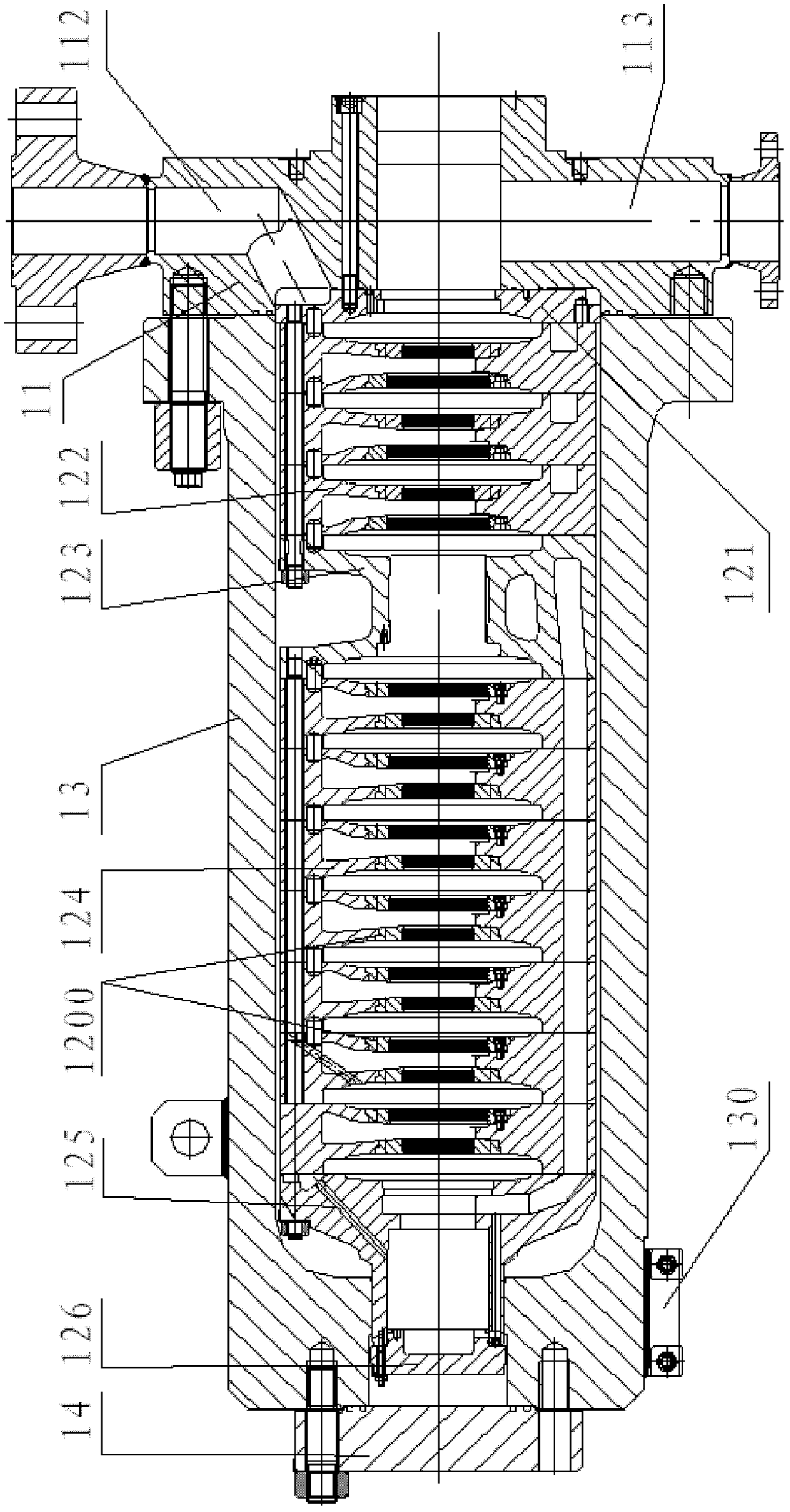

[0061] see figure 1 , the present invention please refer to figure 1 , The upper charging pump used in nuclear power plants includes a stator part 1, a rotor part 2, a bearing part and a shaft sealing device 4. The bearing components include a driving end bearing 31 , an intermediate auxiliary bearing 32 and a non-driving end bearing 33 .

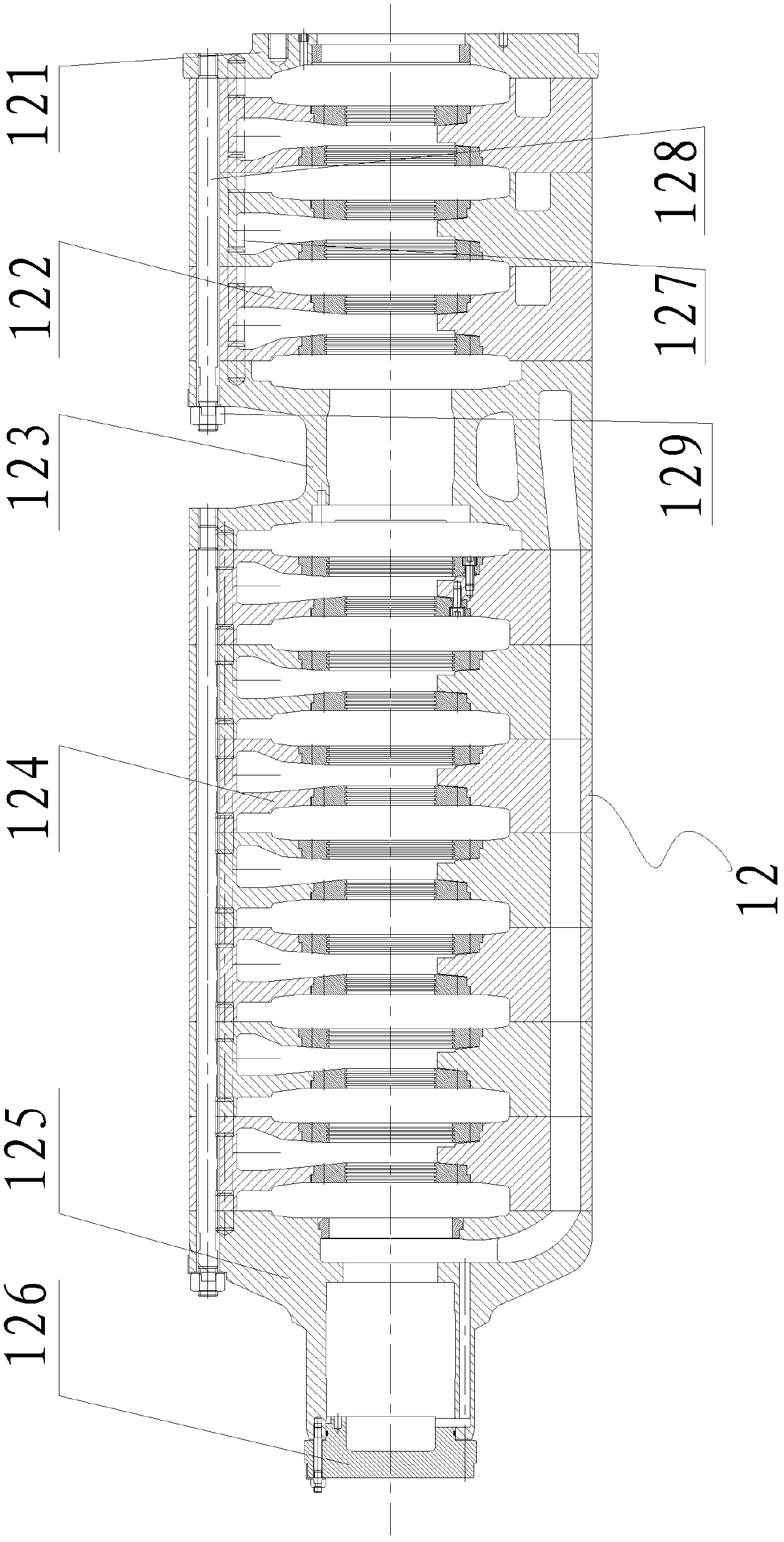

[0062] see again figure 2 , The stator part of the upper charging pump used in the nuclear power plant of the present invention includes a pump head 11, a cylinder body and a tail plate 14 which are sequentially connected back and forth. Among them, the barrel includes an outer shell 12 and an inner shell 13, and a barrel slideway block 130 is provided at the connecting position between the barrel and the pump base to ensure high repositio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com