Machining method to ensure coaxiality of inner and outer splines of hollow shaft

A processing method and hollow shaft technology, which is applied in the field of processing to ensure the coaxiality of the inner and outer splines of the hollow shaft, can solve the problems that the coaxiality of the outer splines cannot be guaranteed, shorten the service life of the product, and affect the assembly quality of the product. Concentricity requirements, improved machining accuracy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

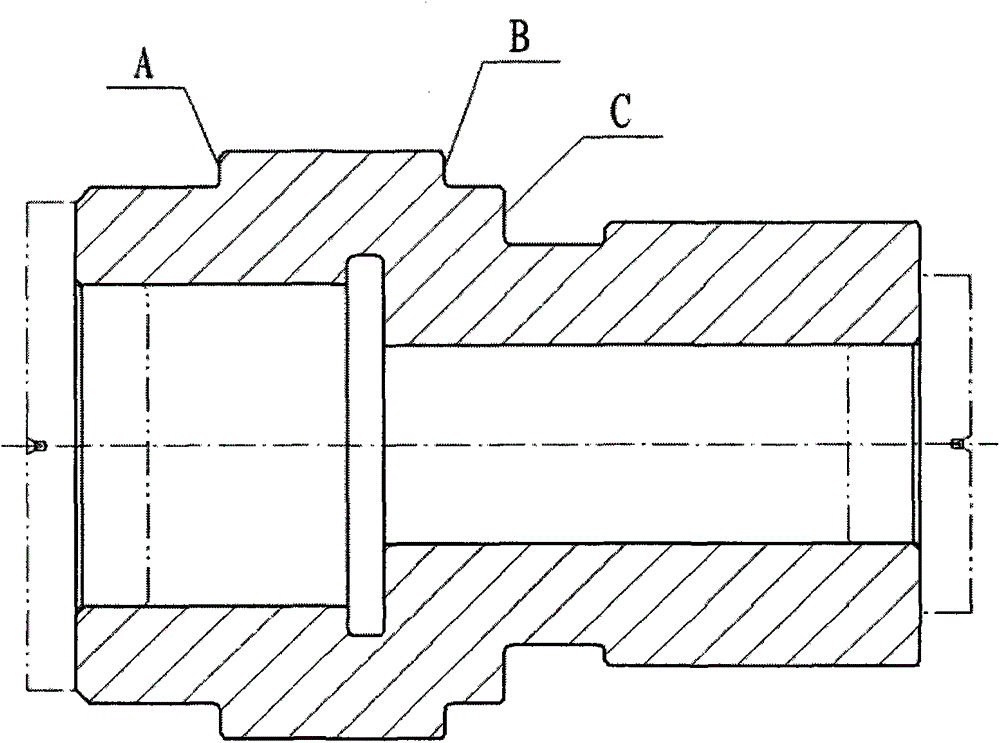

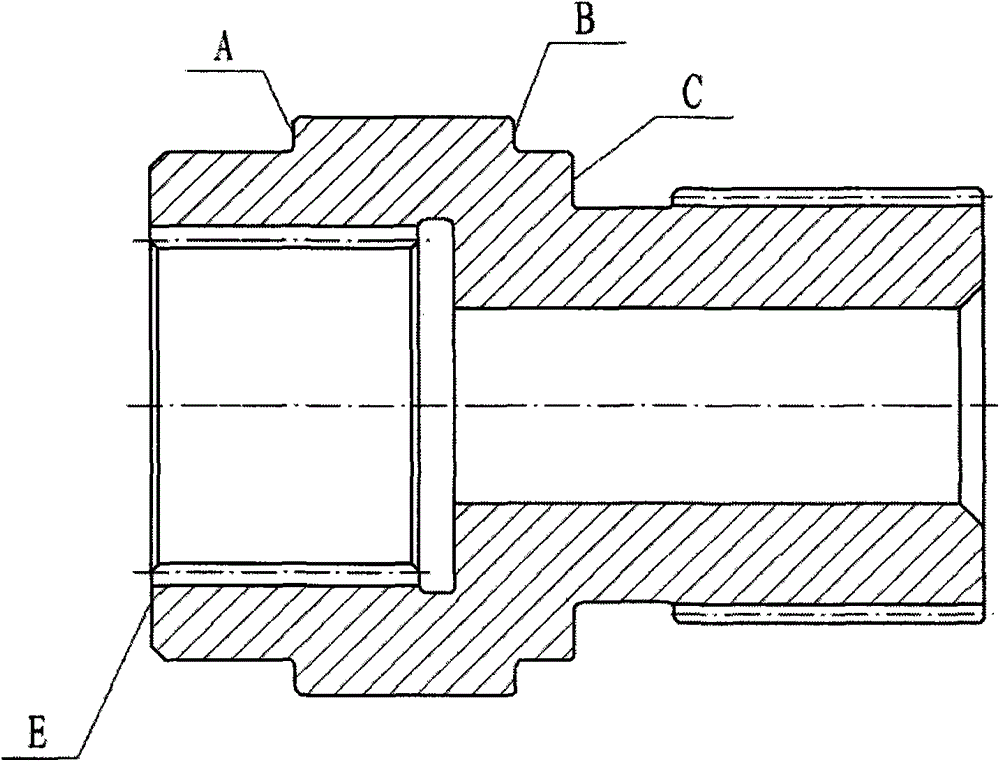

[0009] Depend on Figure 1~2 It can be seen that the process of grinding the spline hole is changed to the process of grinding the outer circle, and the relevant end face must be ground when grinding the outer circle, so that the ground outer circle and the ground end face can be aligned when grinding the spline hole, ensuring The spline hole has the same center as the outer circle. The processing steps to ensure the coaxiality of the inner and outer splines of the hollow shaft are as follows:

[0010] Follow the steps below to complete the machining of the inner and outer splines of the hollow shaft:

[0011] Step 1, rough turning the left end face, outer circle, and hole of the hollow shaft and the right end face, outer circle, and hole of the hollow shaft;

[0012] Step 2, plugging both ends of the hollow shaft and drilling the center hole;

[0013] Step 3, use the central holes at both ends to locate the outer circle of the left end of the hollow shaft and the outer cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com