Multifunctional syngen drill ripping bar

A drilling jig and multi-functional technology, which is applied in the direction of manufacturing tools, drilling/drilling equipment, boring machines/drilling machine components, etc., can solve the problems of insufficient drilling efficiency, improve drilling efficiency and economic benefits, and reduce production costs cost, good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

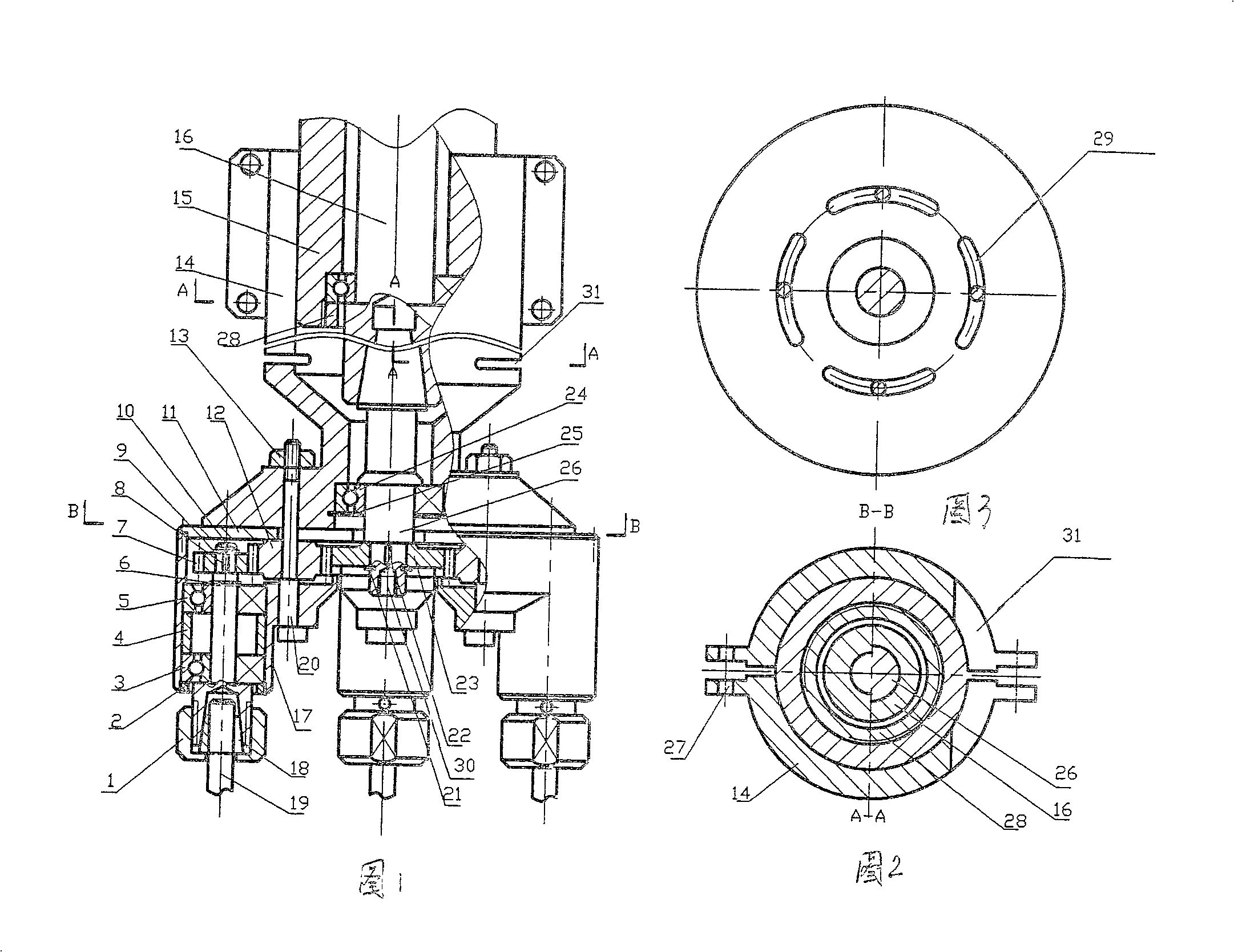

[0015] Such as figure 1 As shown, the drill jig includes a bracket body and a drill chuck body. The bracket body is composed of a bracket 14, a conical shaft 26, and a driving gear 23. In the bearing seat hole, the driving gear 23 is fixed on the conical shaft 26 through the spring inner card 21 and the B flat key 22, and a group of rotating shaft mounting holes 29 are equally distributed around the center of the bracket on the bracket 14, and the above components are assembled into a bracket body; The drill chuck body described above is composed of drill chuck shaft 10, pinion 7, and drill body 17. The second bearing 3, the spacer sleeve 4 and the centripetal thrust bearing 5 are installed in the middle of the drill chuck shaft 10 through the spring retaining ring 6 in sequence. The small end of the drill chuck shaft 10 is installed with the pinion 7 through the spring inner ring 9 and the A flat key 8, the drill chuck shaft 10 is inserted into the bearing seat hole of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com