Installation tool for split type nesting unilateral fastener

An installation tool and split-type technology, which is applied in the field of mechanical assembly and civil engineering engineering, can solve the problems of weakened bolt rods, inability to use fastening installation, restrictions, etc., and achieve the effect of reducing the installation aperture, improving installation efficiency, and reducing negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

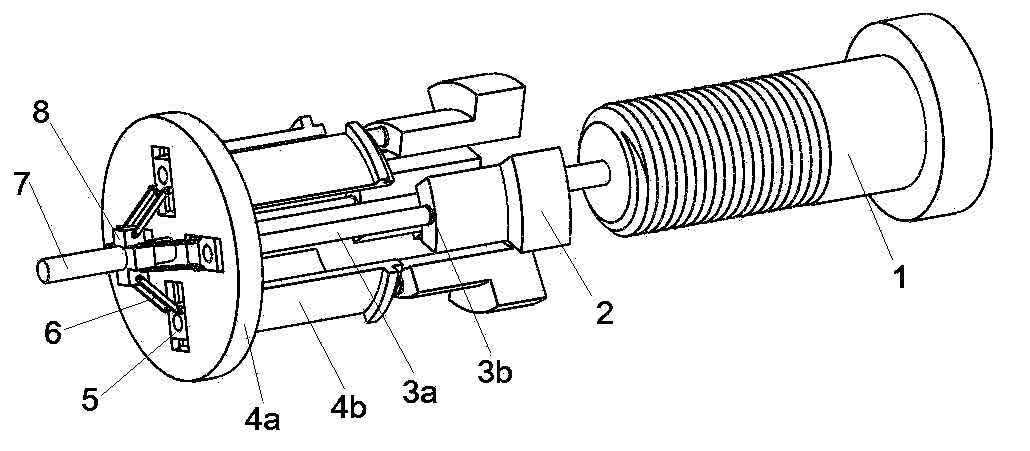

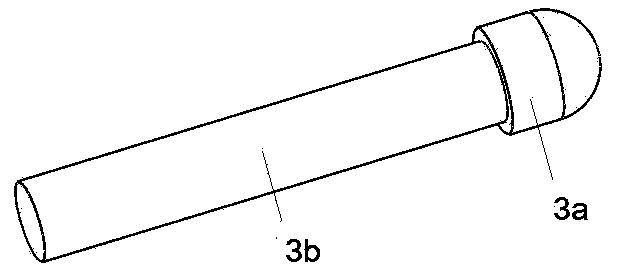

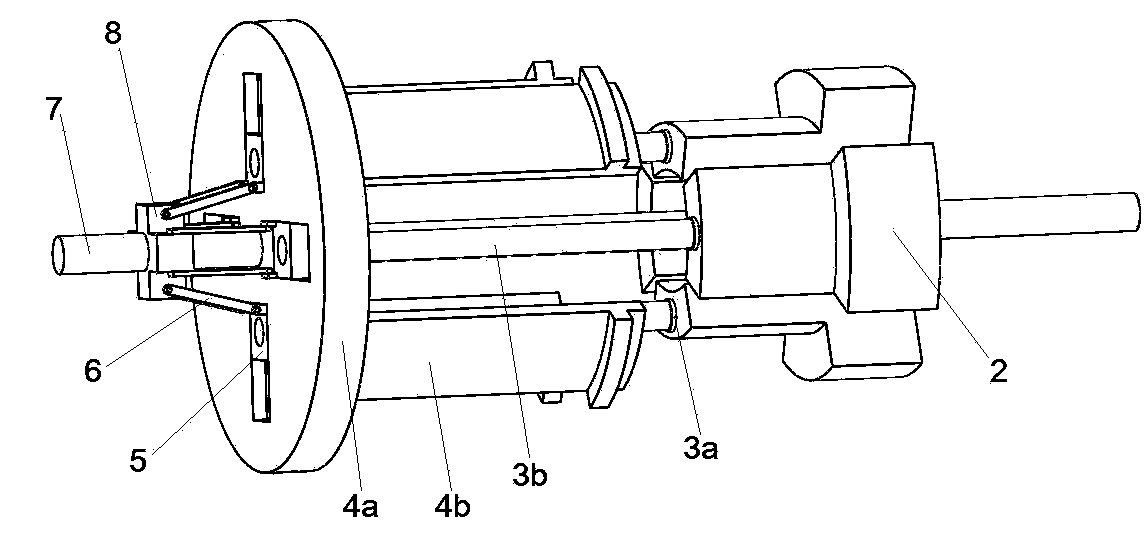

[0028] Embodiment 1: The present invention consists of a rubber sleeve 3a, a split gasket operating lever 3b, a mounting plate 4a, a guide plate 4b, a slider 5, a connecting rod 6, a button bolt operating lever 7, and a hand-push slider 8. The split-type nested unilateral bolt fastener is composed of a round-head bolt 1, a split gasket 2, a flat gasket 10 and a nut 11. The head of the round-head bolt operating rod 7 is provided with a thread to cooperate with the round-head bolt 1. , the interference fit between the rubber sleeve 3a and the split gasket operating rod 3b and the split gasket 2 respectively, the hand-push slider 8 is hingedly connected with several connecting rods 6, and the connecting rods 6 and The slider 5 is hingedly connected, and the hand-push slider 8 can drive several sliders 5 and several split gaskets 2 to move outward together, and the concentric positioning between the installation disk 4a and the installation hole 9c.

[0029] The operating method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com