Portable Waste Welding Consumables Recovery Device

A recycling device and a convenient technology, applied in the field of convenient waste welding material recycling device, can solve the problems of difficult to take out, time-consuming and laborious, difficult to take out, etc., and achieve the effect of good practical application value and promotion value, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

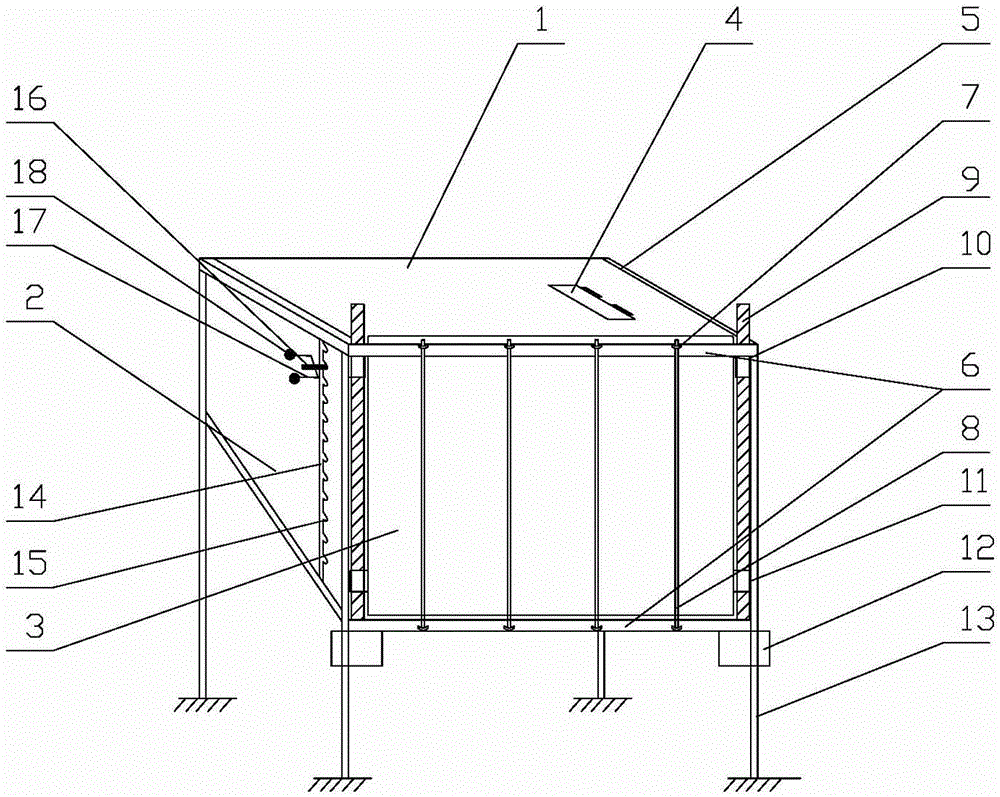

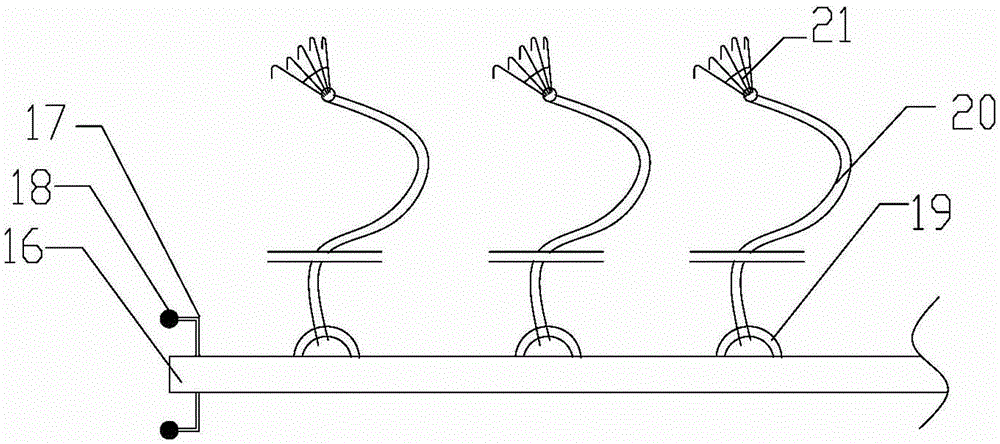

[0024] Such as figure 1 , figure 2 As shown, the portable waste welding consumables recycling device includes: a box body composed of a panel 1, an inclined bottom plate 2, a steel door 3, a back plate and side plates, the panel 1 is provided with an opening 4, and the inclined bottom plate 2 is connected to the horizontal plane. A thick steel plate with an included angle of 30 degrees prevents the waste welding materials from being too heavy to crush the inclined bottom plate 2, and facilitates the discharge of waste welding materials; the up and down driving device is used to drive the steel door 3 to move up and down; the column 13 moves the box The body is fixed on the ground; the door blocking device is located at the front part of the steel door...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com