Yarn guiding frame for braiding yarns of woven bag

A technology of braided wires and woven bags, which is applied in the field of woven bag production equipment, can solve the problems of inability to disassemble, interfere with each other, and affect the effect of lead wires, etc., and achieve the effect of stable and reliable leads, not easy to get stuck, and good effect of lead wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

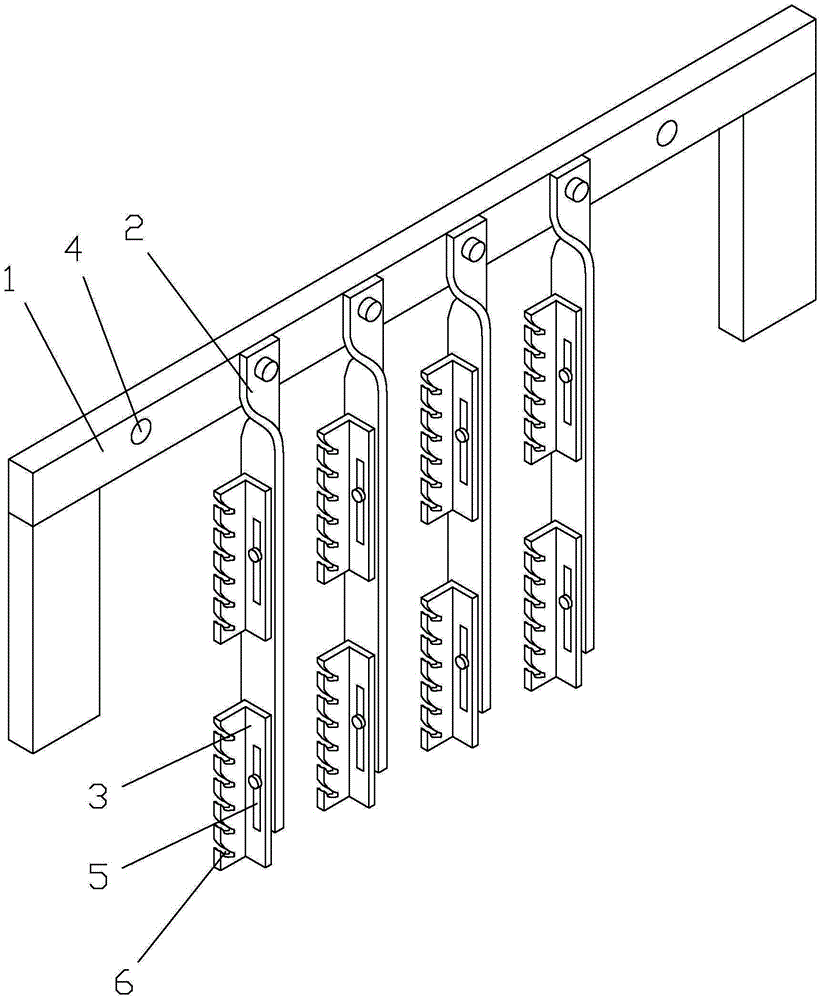

[0013] like figure 1 As shown, the braided wire lead frame of the woven bag includes a fixed frame 1, a fixed plate 2 and a lead plate 3, and the fixed frame 1 is uniformly provided with connection holes 4, and the fixed plate 2 is arranged on the fixed frame 1 through a fastener, and the lead wire The plate 3 is provided with a long groove 5, the lead plate 3 is arranged on the fixed plate 2 through fasteners, and the outer side of the lead plate 3 is uniformly provided with a lead groove 6. The fixing plate 2 is a whole bent folded plate. At least one lead plate 3 is arranged on the fixing plate 2 . There are six lead grooves 6 on the outer side of the lead plate 3 . The notch of the lead groove 6 is inclined upwards, and the width of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com