Drum washing machine drainage structure and method

A technology of drum washing machine and drainage structure, which is applied to other washing machines, washing devices, textiles and paper making, etc., which can solve the problems of residual water freezing, peculiar smell, re-use after a long time, troubles, etc., and achieve convenient drainage and emptying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

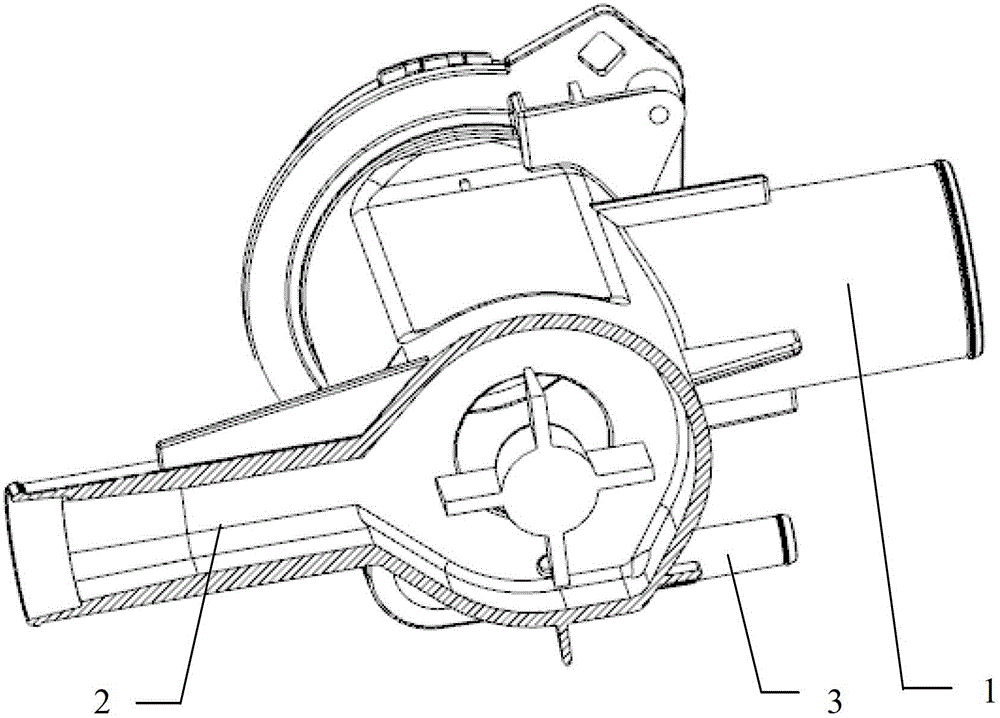

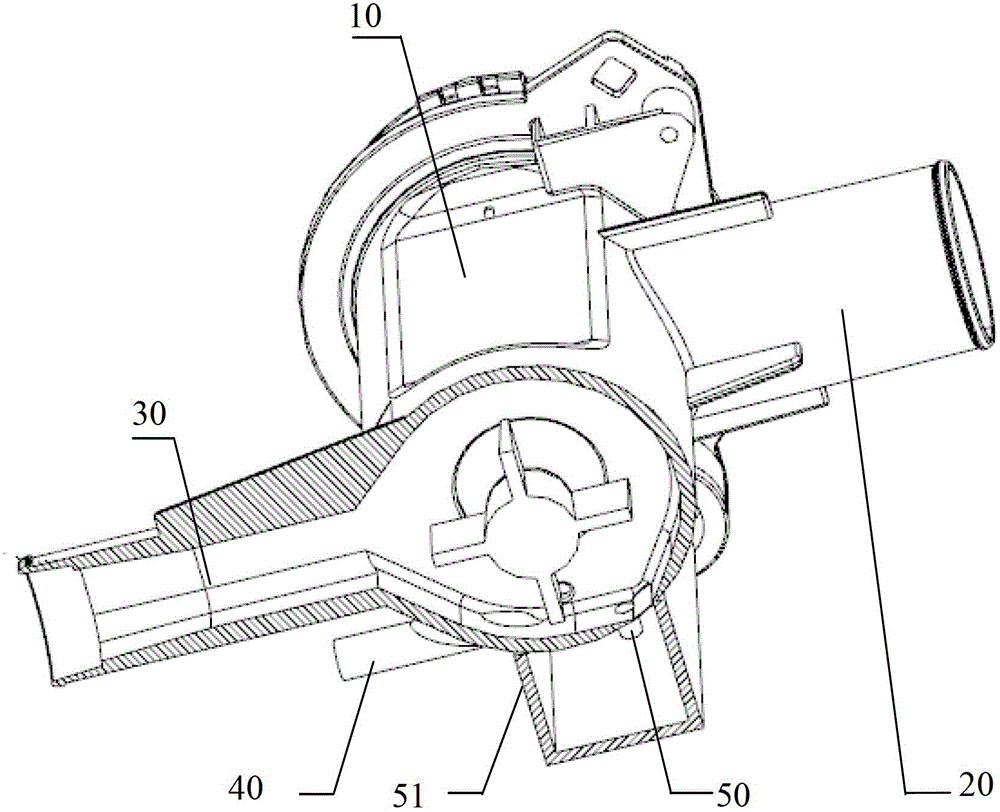

[0029] The invention discloses a drainage structure of a drum washing machine, which includes a drainage pump. The drainage pump includes a pump casing and an impeller located in the pump casing. The pump casing is provided with a water inlet pipe. The drainage structure also includes:

[0030] a first drain for the first discharge of washing water;

[0031] a second drain for discharging residual wash water after draining through the first drain;

[0032] a third drain for washing water remaining after draining through the first drain or the first drain and the second drain;

[0033] Wherein, the first drain port and the second drain port communicate with the outside of the drain pump through the first drain hose and the second drain hose respectively, forming a first drain passage and a second drain passage respectively;

[0034] The third drain port is directly connected to the outside of the drain pump or connected to the outside of the drain pump through a third drain ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com