Sliding rotating shaft mechanism and armrest box armrest

A technology of hinge and armrest cover, which is applied in the direction of pivot connection, passenger space, etc., to achieve the effect of reducing restrictions and meeting different requirements of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

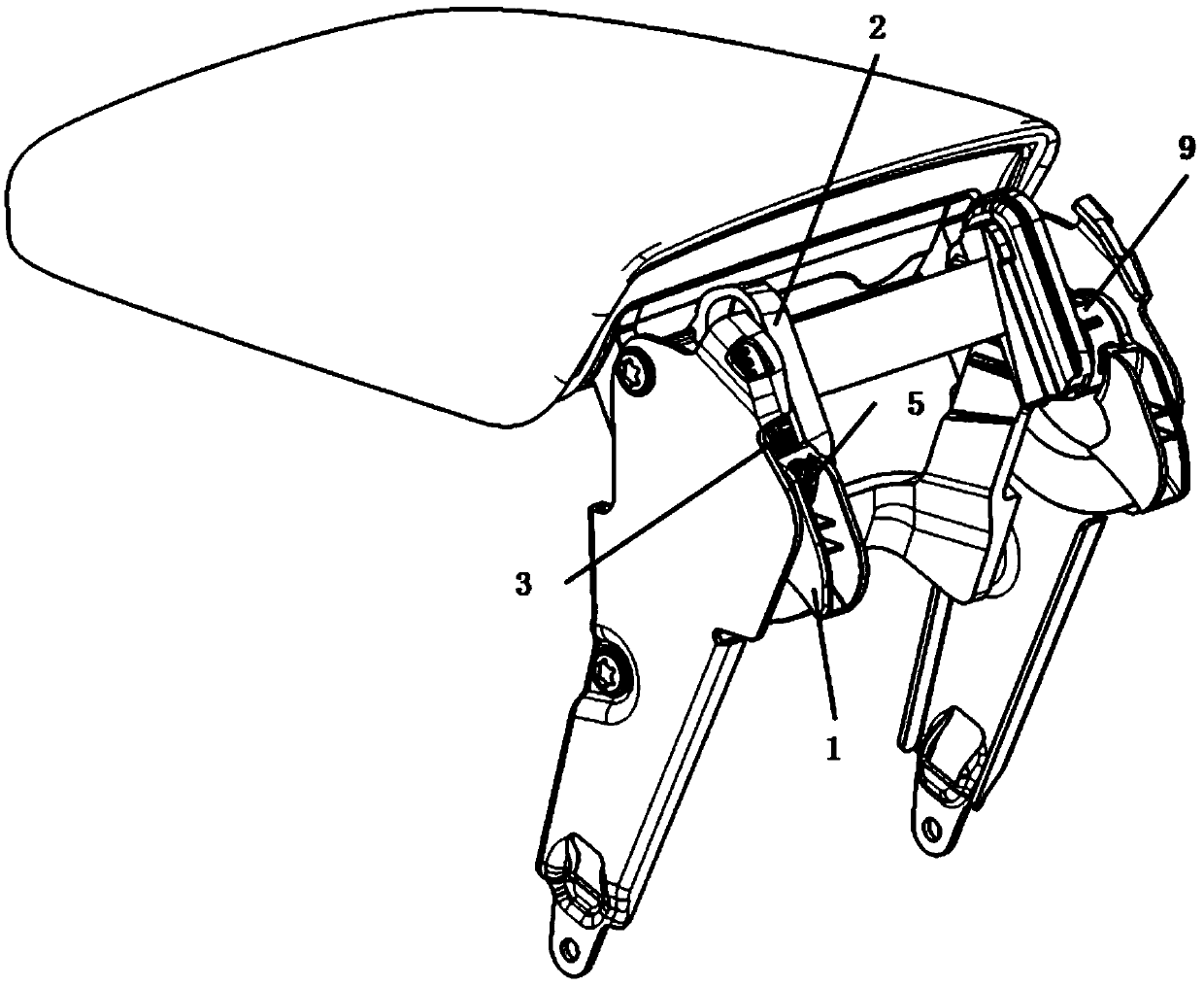

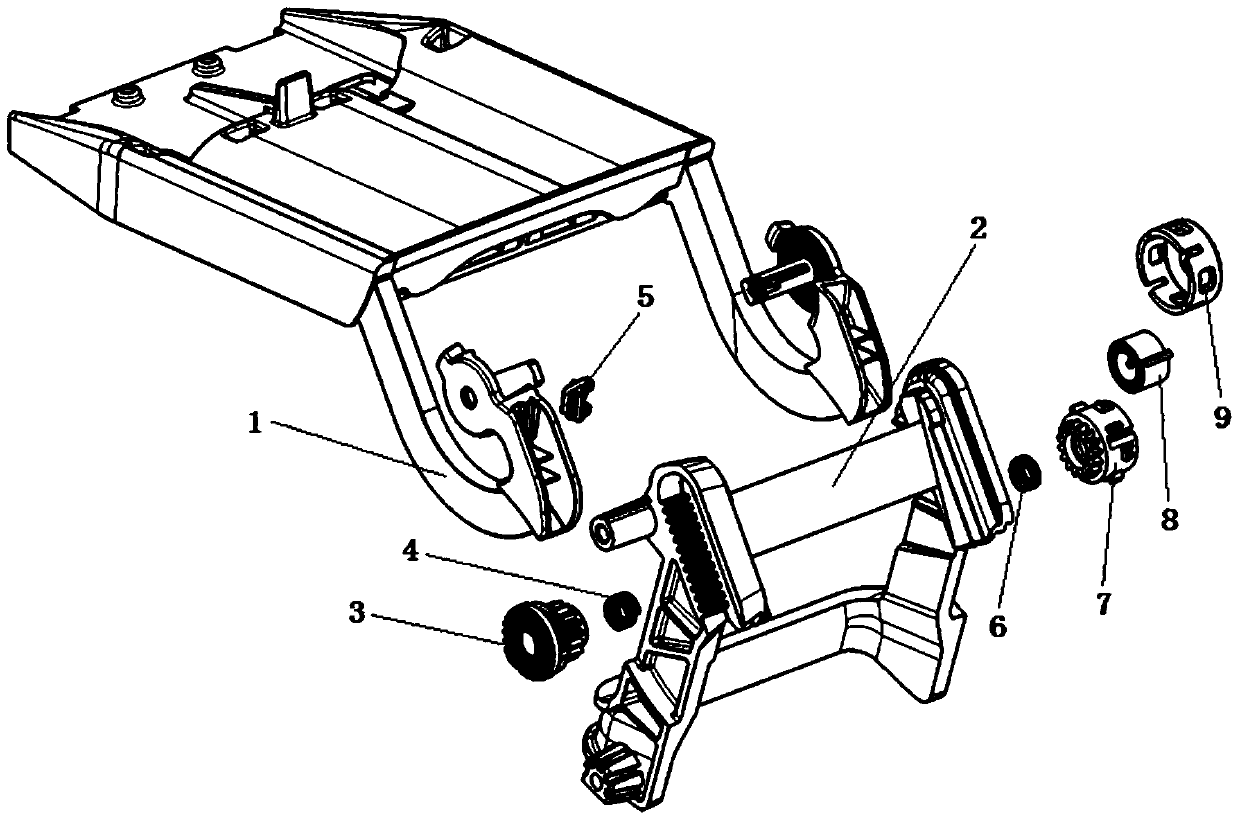

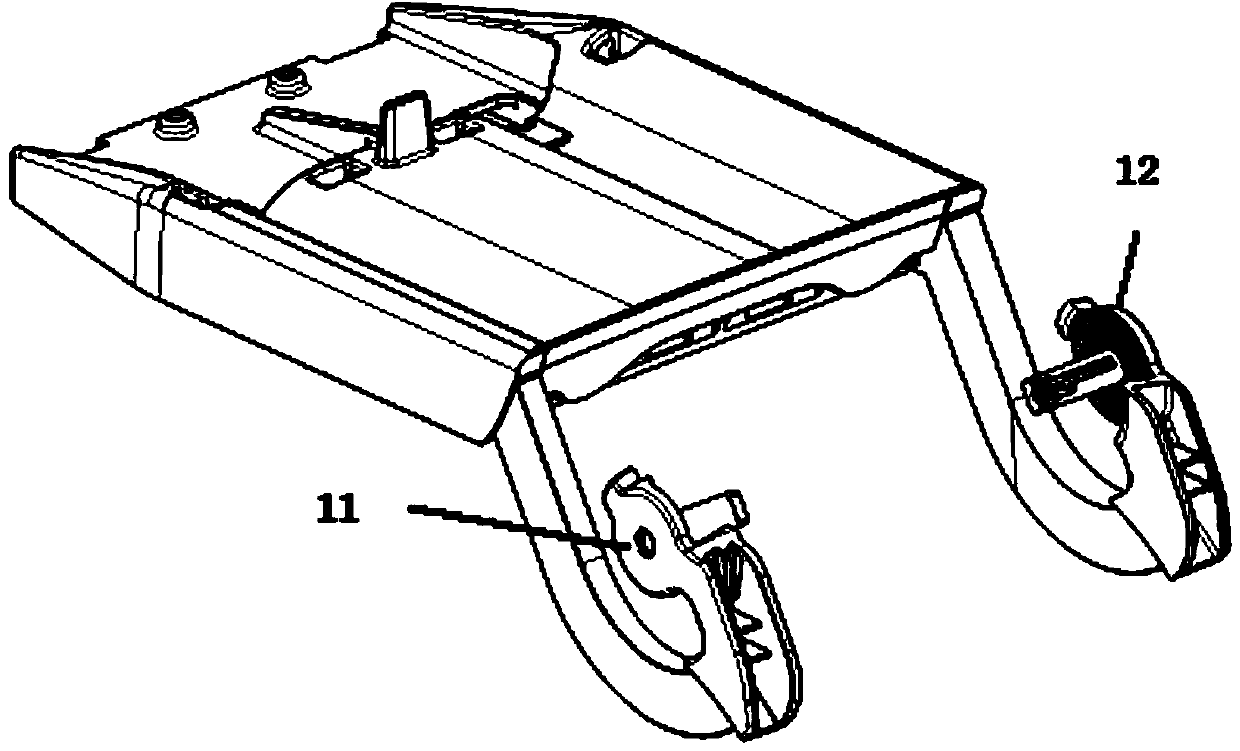

[0071] see Figure 1-25 , In the following embodiments, the armrest of the armrest box with the sliding and rotating shaft mechanism of the present invention is taken as an example. The present invention is a sliding and rotating shaft mechanism, which includes: a sliding and rotating cantilever 1, a sliding and rotating track bracket 2, a straight-toothed one-way ratchet 3, a left helical spring 4, a stop spring 5, a right helical spring 6, and a straight tooth Coil spring guard 7, coil spring 8 and two-way ratchet guard 9.

[0072] The sliding and rotating cantilever 1 is generally integrated on the armrest cover part, which includes a left arm 11 and a right arm 12 arranged at intervals on the left and right, wherein:

[0073] One end of left arm 11 is connected on the armrest cover plate part, and its other end has: left installation wall 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com