An electrical connector for moving parts

A technology of electrical connectors and moving parts, applied in the field of automotive electronics, can solve problems such as short circuit, broken wire harness, poor fixing of moving parts, etc., to achieve reliable transmission, eliminate influence, and reduce poor fixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

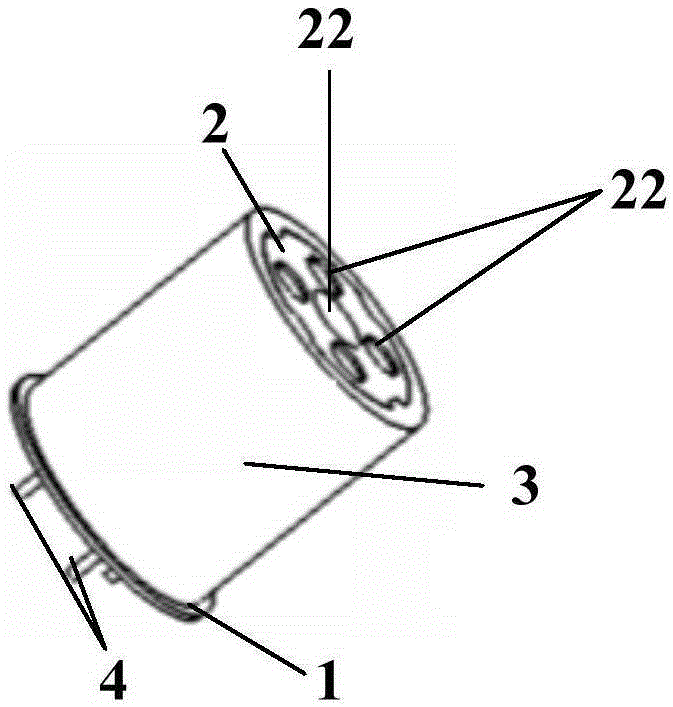

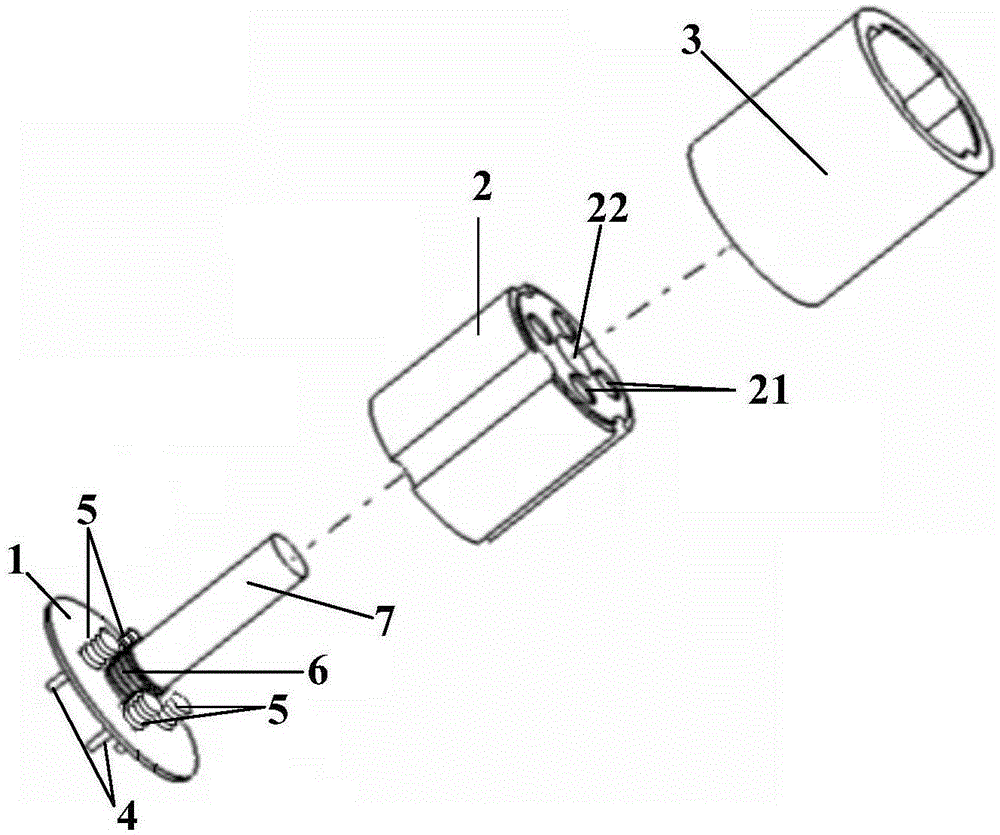

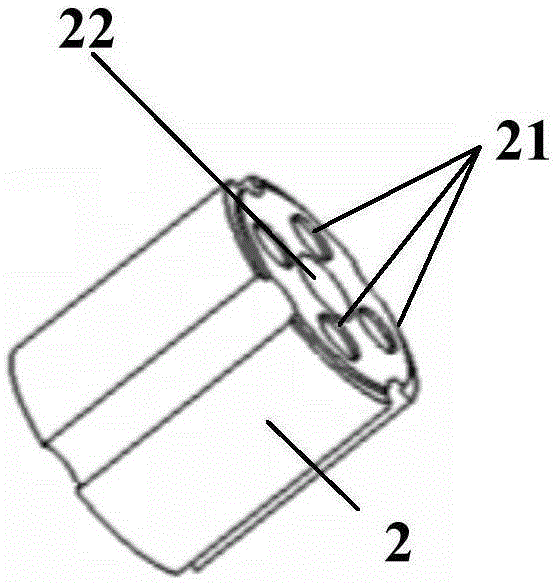

[0022] The embodiment of the present invention discloses an electrical connector for moving parts, which includes a conductive terminal, an accommodating portion, an insulating shell and a base; wherein, the accommodating portion is provided with a first through hole corresponding to the conductive terminal, and the conductive terminal Embedded in the first through hole; the insulating shell is fixed on the base, and a cavity with an open top is formed between the base and the base, and the receiving part is located in the cavity and can move in the cavity; the upper surface of the base corresponds to At the position of the first through hole, a first spring perpendicular to the base is installed, and the first spring does not contact the conductive terminal in the first through hole in a natural state; at the center of the upper surface of the base, install There is a second spring perpendicular to the base, one end of the second spring is fixedly connected to the base, and th...

Embodiment 2

[0033] Another embodiment of the present invention also discloses an electrical connector, which includes more than two conductive terminals (this embodiment takes four conductive terminals as an example), an accommodating part, an insulating shell and a base, such as Figure 1 to Figure 4 As shown, wherein, the first through hole 21 corresponding to each conductive terminal 8 is opened on the receiving part 2, and each conductive terminal 8 is embedded in the corresponding first through hole 21; the insulating shell 3 is fixed on the base 1, And form a cavity with an open top between the base 1, the accommodating part 2 is located in the cavity, and can move in the cavity; at the positions corresponding to the first through holes 21 on the upper surface of the base 1, Both are installed with a first spring 5 perpendicular to the base 1, and the first spring 5 is not in contact with the conductive terminal 8 in the corresponding first through hole 21 in a natural state; at the ...

Embodiment 3

[0044] Another embodiment of the present invention also discloses an electrical connector, which includes all the technical features in Embodiment 1 and Embodiment 2, and can also be made according to the size of the harness hole or the layout space and other constraints. Different brackets are used to realize corresponding fixing schemes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com