A seed box connection device for a seed meter

The technology of a connecting device and a seed meter, which is applied in the field of agricultural machinery, can solve the problems of seed surface damage, poor seed mobility, inconvenient seed picking, etc., and achieves the effects of low manufacturing cost, flexible use and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

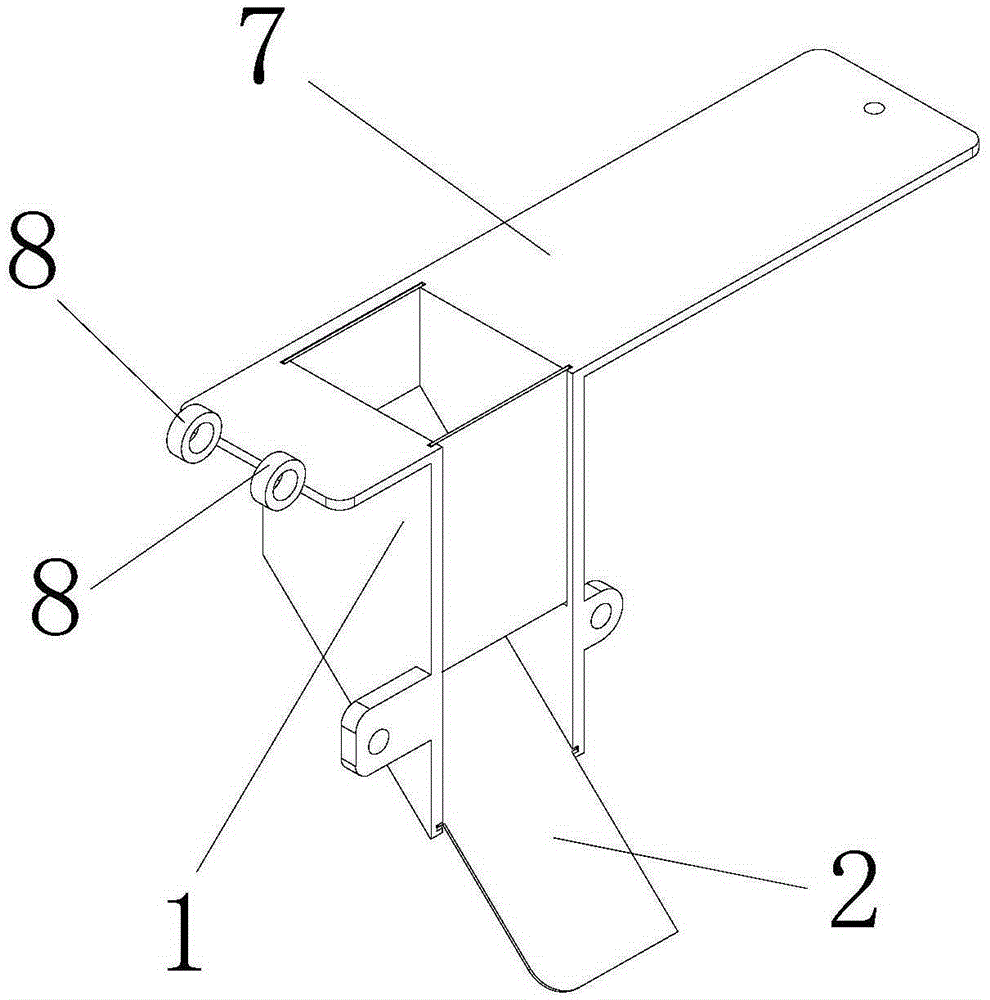

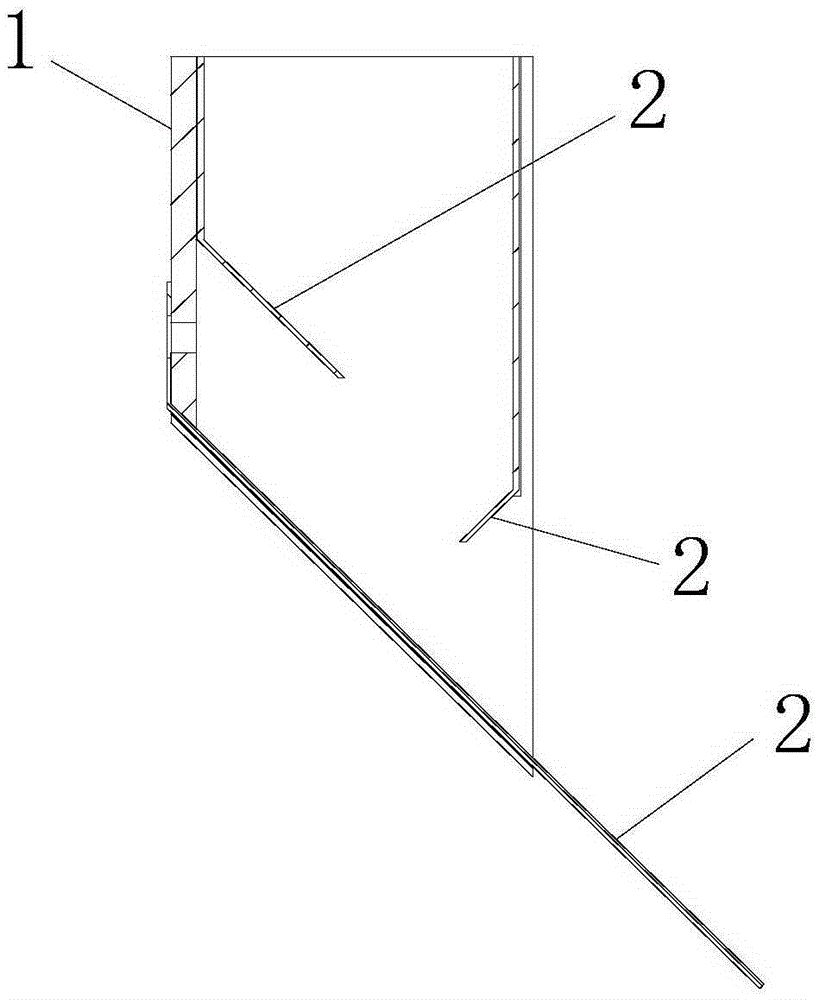

[0030] A seed box connection device for a metering device, including a cylinder body 1 and at least two seed guide plates 2. This embodiment takes three pieces as an example for illustration; the seed guide plates 2 are arranged up and down on the inner wall of the cylinder body 1, and two adjacent The seed guide plate 2 is relatively arranged, and the seed guide plate 2 on the top is inclined downward toward the seed guide plate 2 opposite to it at the bottom. Outlet of cylinder 1.

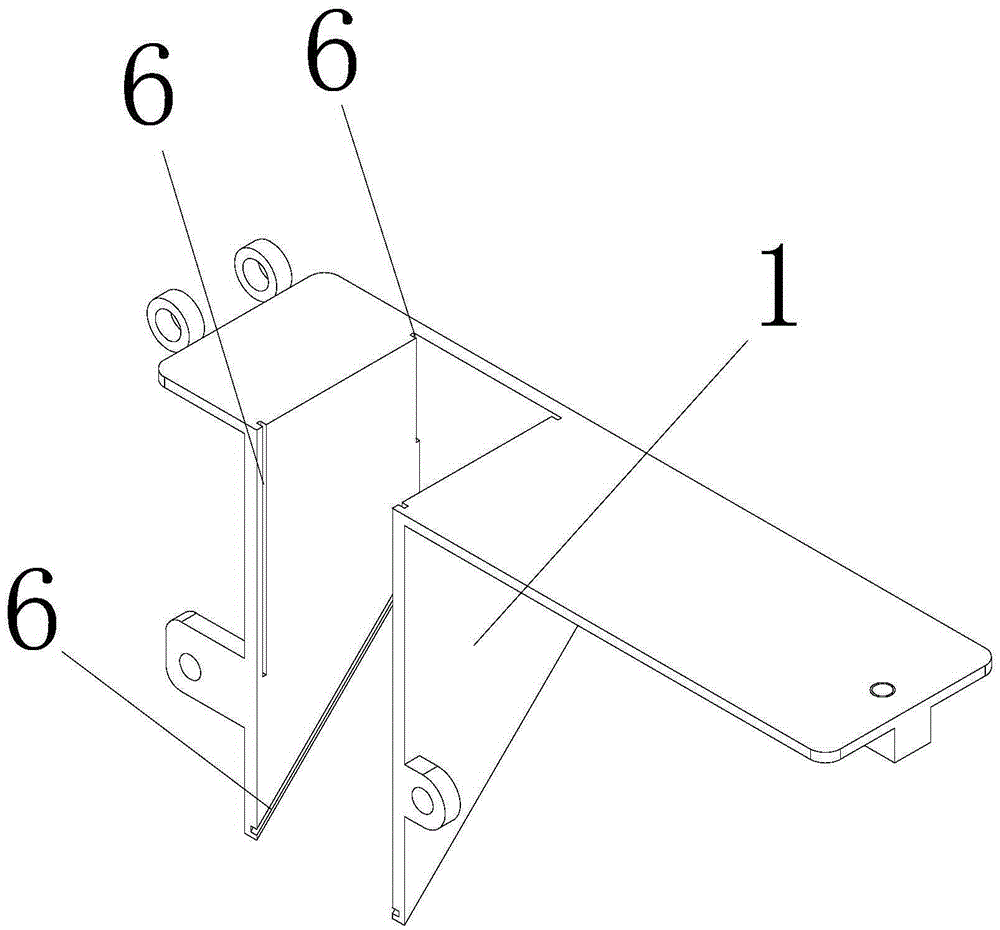

[0031] The seed guide plate 2 includes a connecting section 3 and a guiding section 4 , the guiding section 4 is arranged obliquely below the connecting section 3 , and the connecting section 3 is connected with the cylinder body 1 . Connecting tabs 5 protrude from both sides of the connecting section 3 of the seed guide plate 2 , and a chute 6 is vertically opened at the joint between the cylinder body 1 and the seed guide plate 2 , and the tabs 5 are connected in the chute 6 . The angle betwee...

Embodiment 2

[0034] This embodiment differs from Example 1 in that: the corresponding part or all of the seed guide plate 2 on the cylinder body 1 is provided with a guide section slot at the connection position, and the guide section 4 of the seed guide plate 2 passes through the guide section 4 from the outside of the cylinder body 1. The section slot is inserted into the cylinder body 1, and the connecting section 3 of the seed guide plate 2 is fixedly connected with the cylinder body 1. Preferably, the connecting section 3 of the seed guiding plate 2 is provided with a threaded hole 9 , and the connecting section 3 is connected with the threaded hole 9 through bolts to fix the barrel 1 and the seed guiding plate 2 .

Embodiment 3

[0036] The difference between this embodiment and Examples 1 and 2 is that the seed guide plate 2 located at the bottom is set in the manner of Embodiment 2, and the other seed guide plates 2 are set in the manner of Embodiment 1.

[0037] The working process and working principle of the present invention: the present invention makes the seed flow in a zigzag circuitous flow by arranging a plurality of seed guide plates staggered in the cylinder, and the size and angle of the seed guide plates can be determined according to the needs of the seeds. When the seeds reach the seed filling chamber through the present invention, they are affected by the seed guide plate, so that the seeds cannot directly reach the seed filling chamber, and the seeds are stratified by several times of the seed guide plate, so that the seeds arriving at the seed filling chamber are in a state of one layer To achieve the role of stratification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com