Livestock breeding house

A breeding board and housing technology, applied in the field of livestock breeding housing, can solve problems such as inability to remove feces, and achieve the effects of simple structure, high efficiency, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

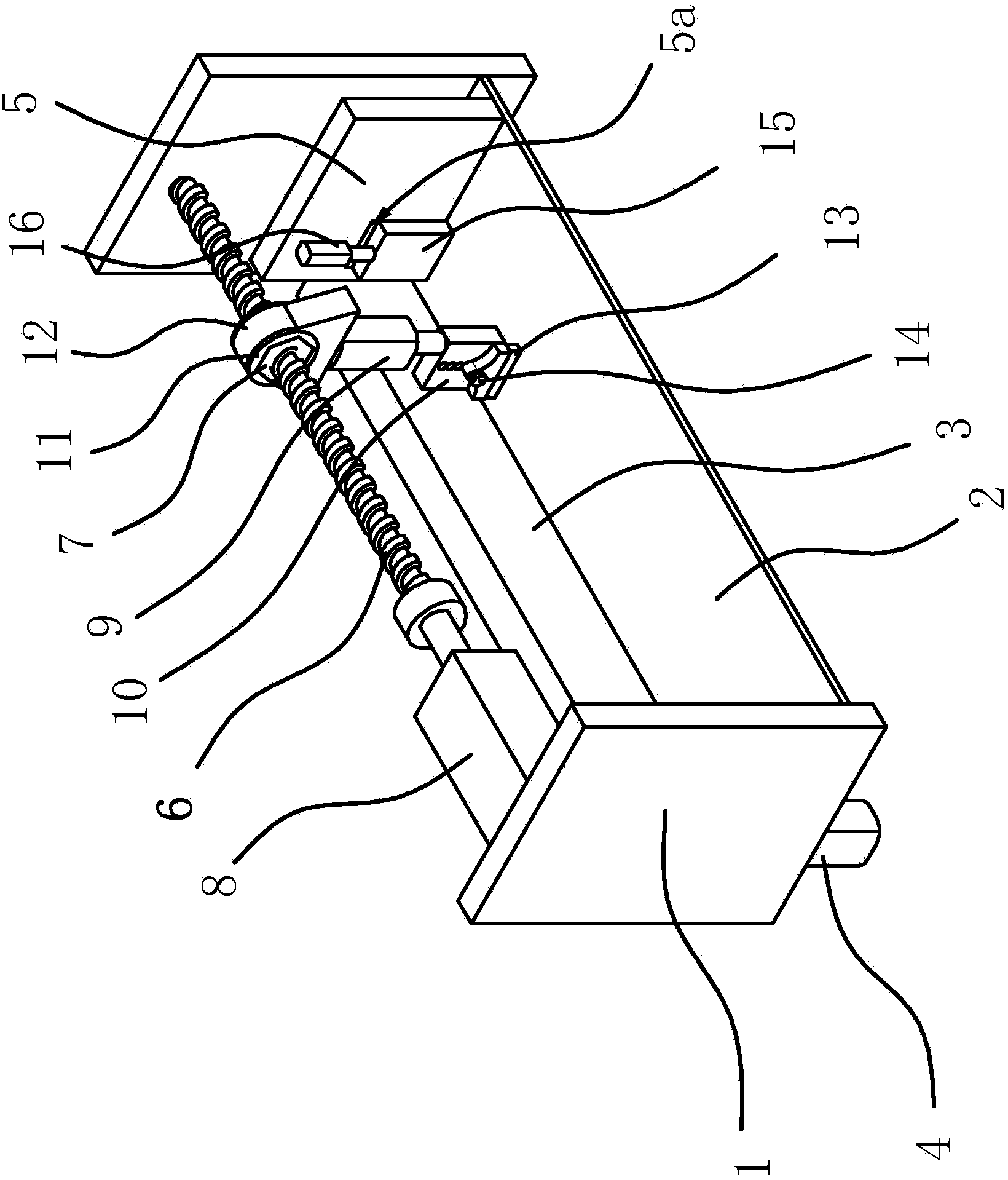

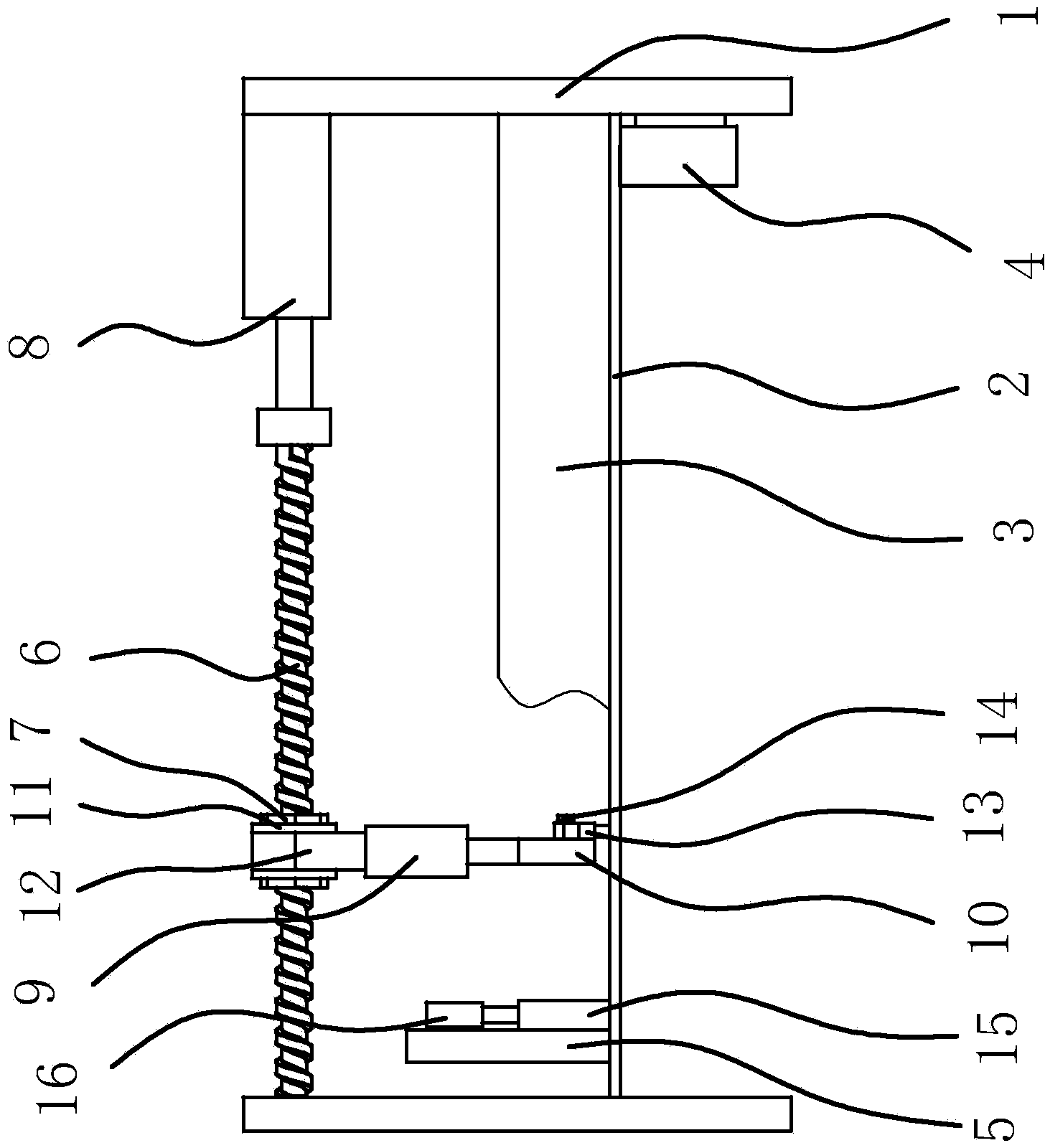

[0028] Such as figure 1 with 2 As shown, a livestock breeding house includes a house body 1 with a horizontal floor, and a partition board 2 that can seal and separate the space in the house body 1 into an upper space and a lower space is provided in the house body 1. Specifically, the house body The left inner wall and the right inner wall of 1 are provided with installation grooves for installing the partition 2, the height of the installation groove is equal to the thickness of the partition 2, and the partition 2 is embedded in the installation grooves on the left inner wall and the right inner wall , it is very convenient to disassemble and install the dividing plate 2 in this way. The partition board 2 is provided with a culture plate 3, the right end of the culture plate 3 abuts against the inner wall of the room body 1, the lower part of the culture plate 3 right end is provided with a cylinder one 4, and the cylinder one 4 is in the lower space, and the piston rod of...

Embodiment 2

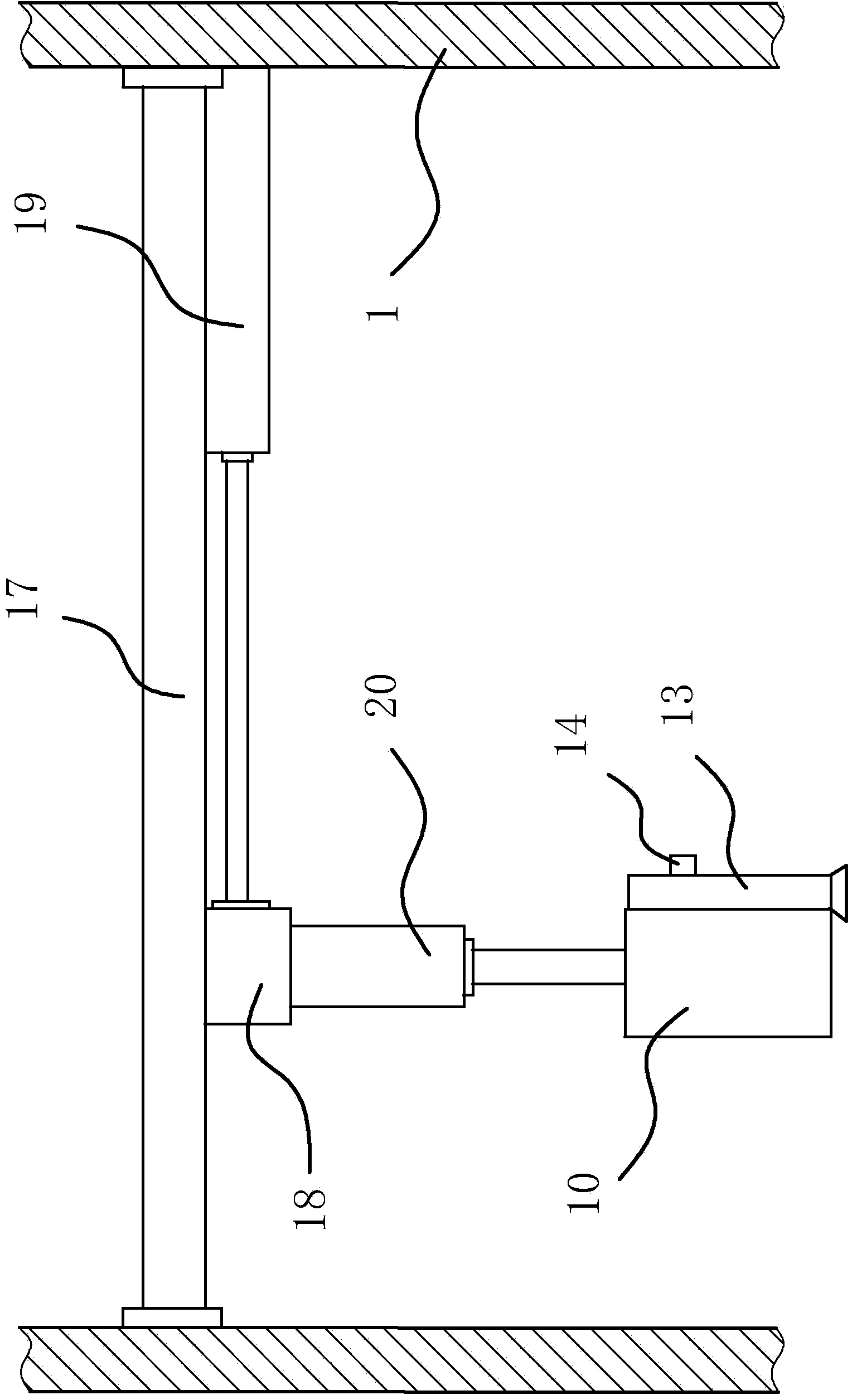

[0036] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in Embodiment 1, the manure scraping device includes a screw rod 6, a nut 7, a motor 8, a cylinder 9, a manure scraper 10, a bearing 11 and bearing seat 12; and in the second embodiment, as image 3 As shown, the manure scraping device includes a guide rail 17, a slider 18, a horizontal cylinder 19, a vertical cylinder 20 and a manure scraper 10, the guide rail 17 is fixed on the top of the house body 1 by screws, and the slide block 18 is slidably arranged in the guide rail 17 , the horizontal cylinder 19 is fixed on the top of the right side of the room body 1 by screws, the piston rod of the horizontal cylinder 19 is fixed to the slide block 18, the cylinder body of the vertical cylinder 20 is fixed on the bottom of the slide block 18 by screws, and the vertical cylinder The piston rod of 20 is vertically downwards, and the dung scraper 10 is fixed at...

Embodiment 3

[0038] The structure and principle of the present embodiment are basically the same as those of the first embodiment, except that in the first embodiment, the opening and closing structure includes an opening and closing plate 15 and a cylinder three 16; and in the third embodiment, as Figure 4 As shown, the opening and closing structure includes an opening and closing plate 15, a pulley 21, a connecting rope 22 and a hook 23. The upper end of the opening and closing plate 15 is hinged on the vertical plate 5 through a hinge, and the pulley 21 is fixed on the left wall of the room body 1, and the pulley 21 is above the hinge point of the opening and closing plate 15 and the vertical plate 5. Three rings 24 are fixed on the left wall of the room body 1 from top to bottom. One end of the connecting rope 22 is fixed at the lower end of the opening and closing plate 15, and the other end of the connecting rope 22 The pulley 21 is fixedly connected with the hook 23, and the hook 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com