Improved liquid stirring device

A stirring device and improved structure technology, applied in the field of machinery, can solve the problems of affecting the taste of ingredients, destroying ingredients, prolonging the production cycle of pastries, etc., and achieve the effect of improving stirring efficiency and reducing stirring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

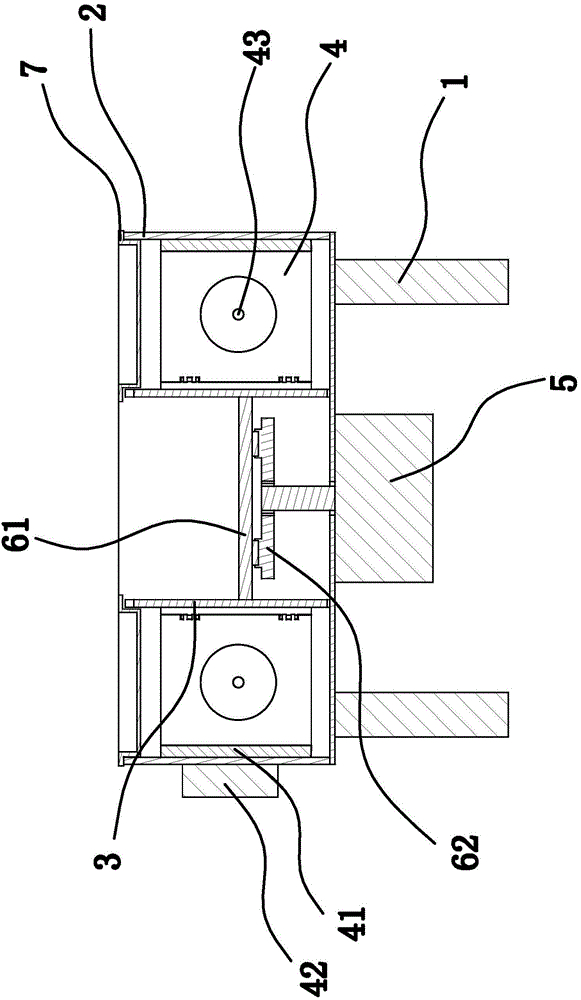

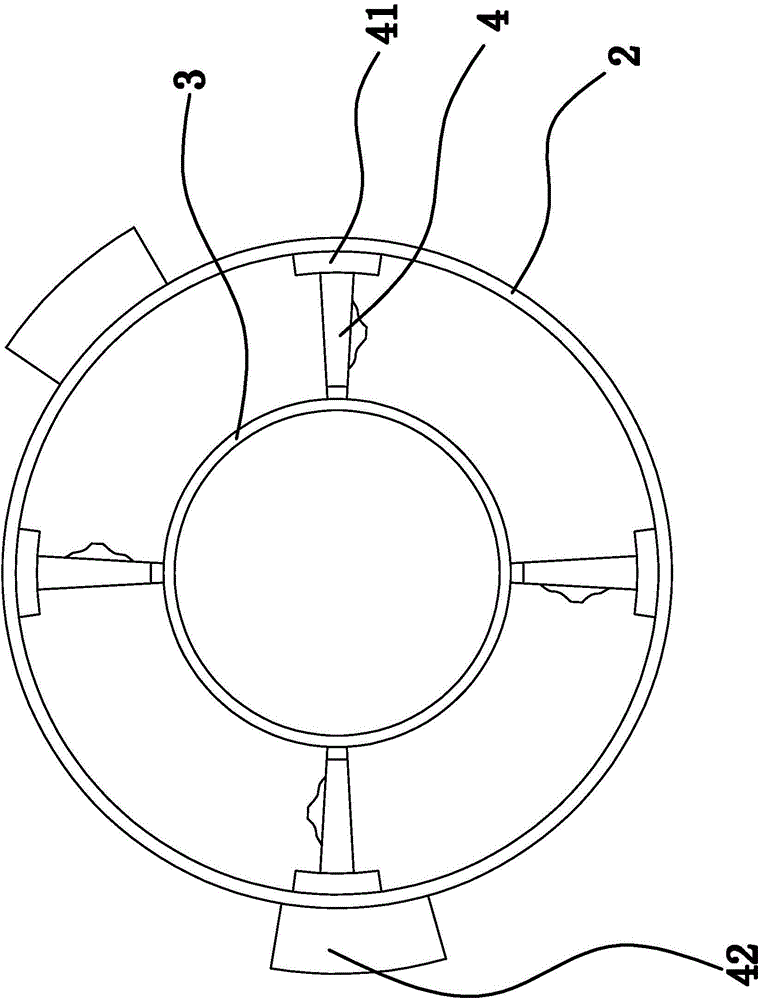

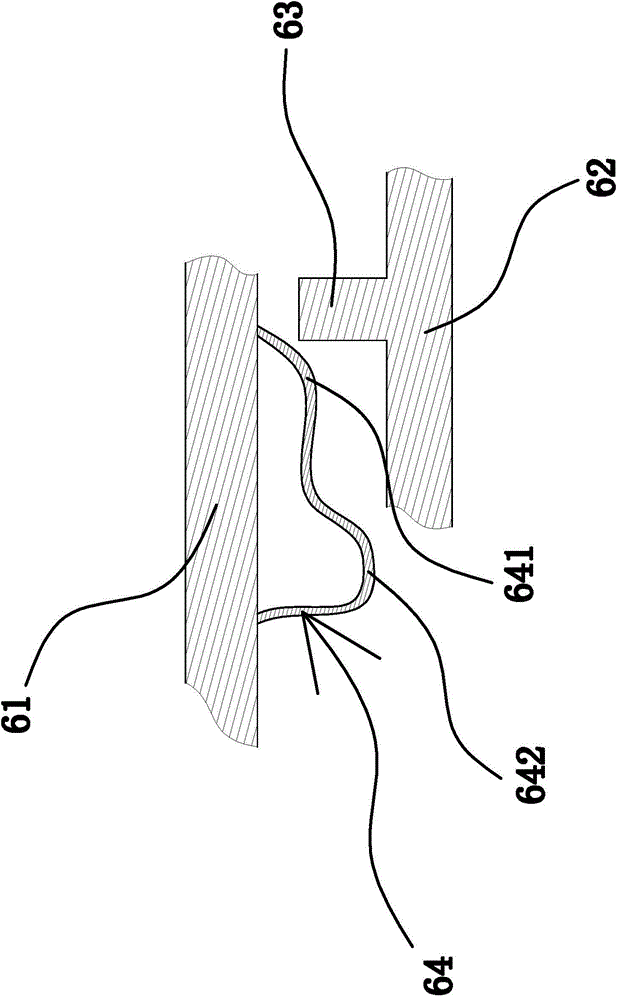

[0025] Such as figure 1 , figure 2 and Figure 4 As shown, the mixing device includes a support 1, a mixing bucket 2 is fixedly arranged on the support 1, a roller 3 is arranged in the mixing bucket 2, and a plurality of stirring blades 4 are hinged on the outer wall of the roller 3, and the outer wall of the mixing blade 4 There is an iron adsorption strip 41 at the end, at least one permanent magnet 42 is fixedly arranged on the outer wall of the mixing bucket 2, and an overflow hole 43 is arranged in the middle of the stirring blade 4, and each stirring blade 4 divides the mixing bucket 2 into a plurality of cavities. The drive motor 5 drives the stirring blade 4 to rotate in the mixing bucket 2, so that the liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com