Equipment for removal of metallic iron in silicon material

A metal iron and equipment technology, which is applied in the field of equipment for removing metal iron in silicon material, can solve the problems of affecting product quality, harmful product minority carrier life, and needs to be improved, etc., and achieves the effect of improving the effect of iron removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific examples.

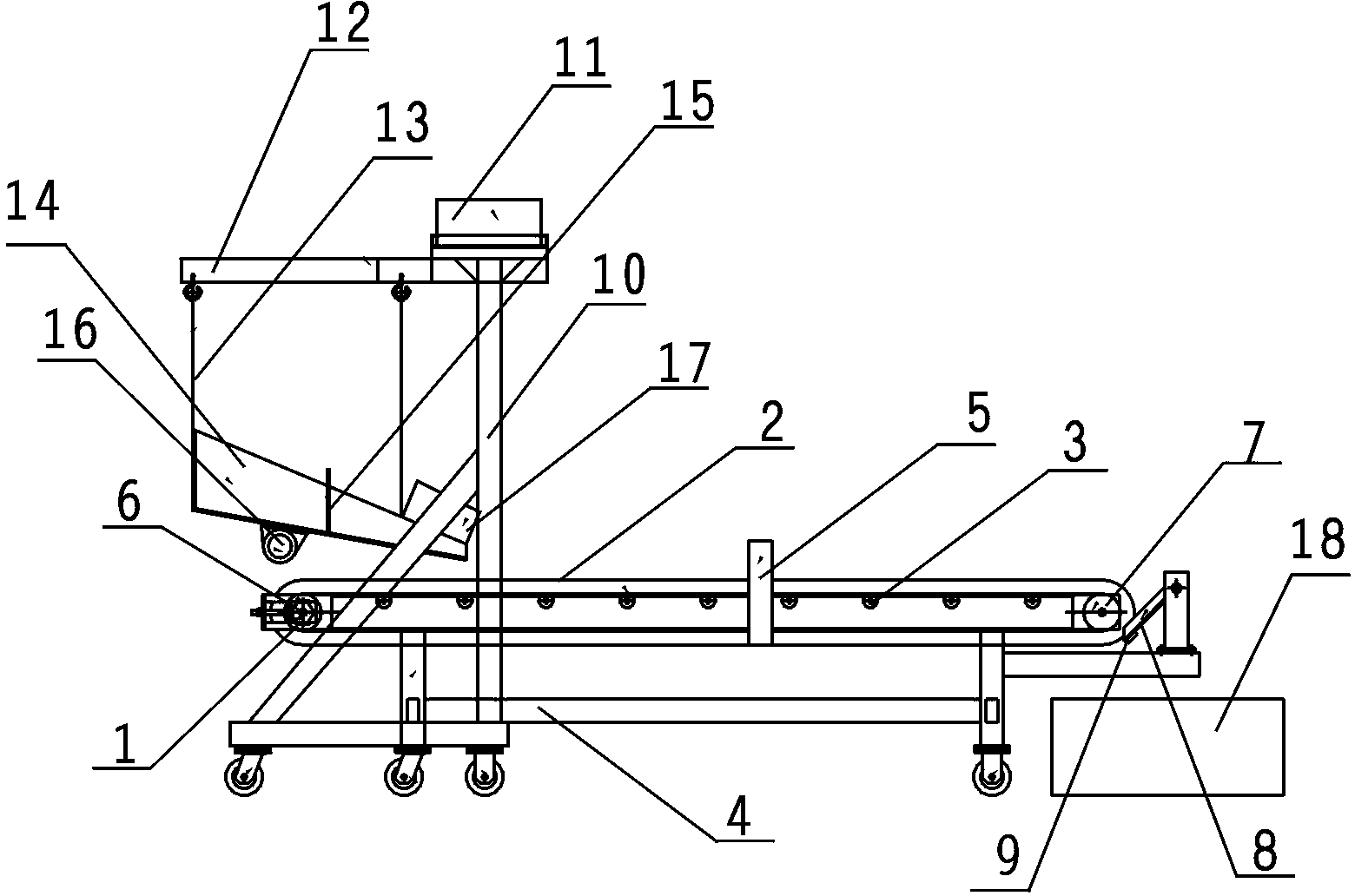

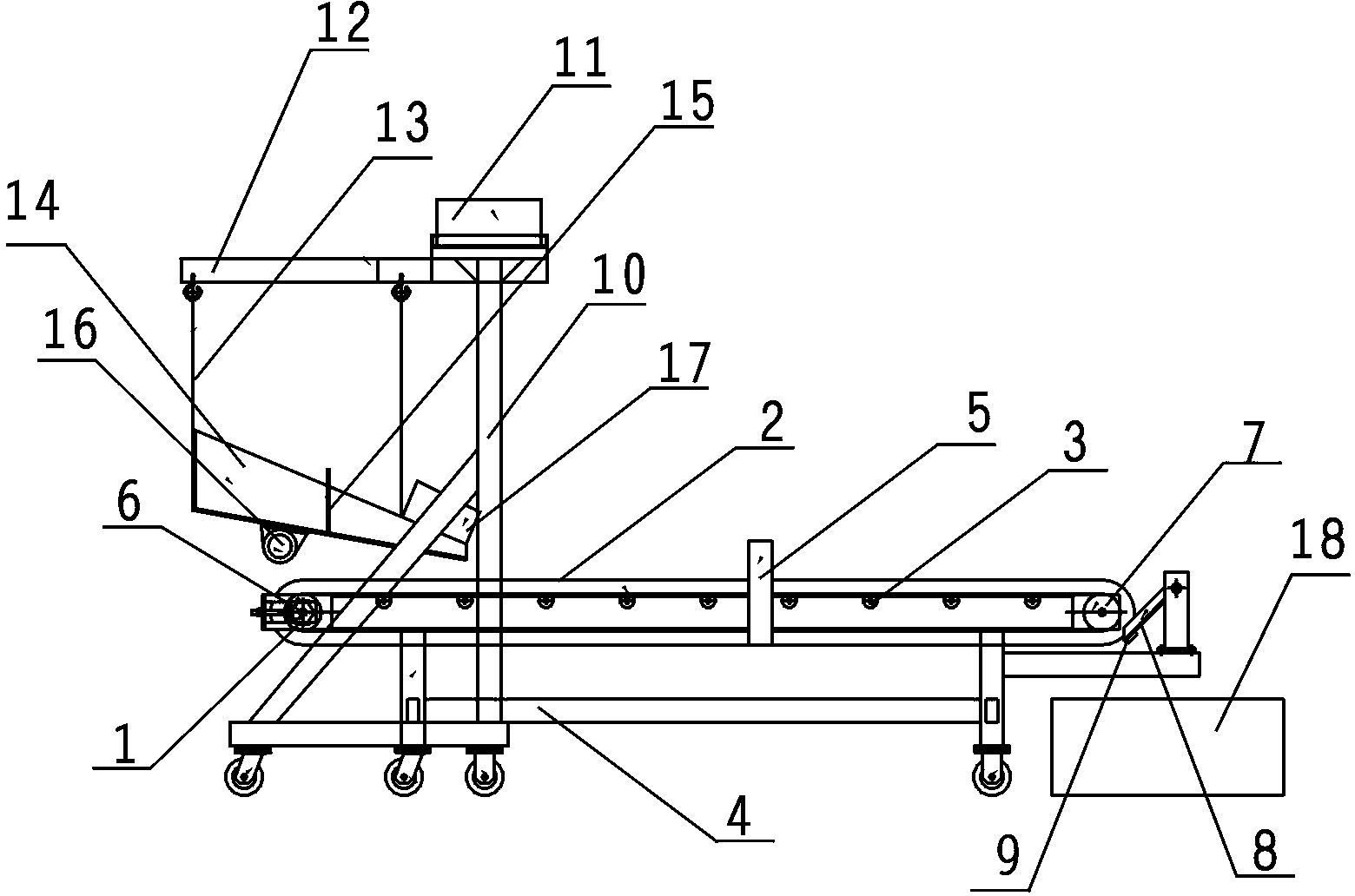

[0012] refer to figure 1 and figure 2 , the equipment for removing metal iron in the silicon material includes a uniform feeding device and a conveying device, the feeding trough 14 in the uniform feeding device is suspended on the hook 12 of the uniform feeding rack 10 by a steel wire rope 13, and the limiting baffle 15 is close to the feeding trough 14 The bottom of the feeding chute 14 is divided into two parts, the feed end and the discharge end. The top of the discharge end of the feeding chute 14 is provided with an electromagnet 17, and the electromagnet 17 is powered by the electromagnetic iron removal power supply box 11, and the bottom of the feeding chute 14 is provided with There is a frequency-modulated vibrator 16, and the discharge end of the feeding trough 14 is located at the upper part of one end of the conveying frame 4 in the conveying device; A number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com