Large-amplitude sandwich-type piezoelectric ultrasonic compound transducer

A piezoelectric ultrasonic, sandwich-type technology, applied in the direction of the fluid using vibration, can solve the problem of limiting the ultrasonic range of the ultrasonic transducer, and achieve the effect of increasing the ultrasonic radiation area and increasing the ultrasonic radiation power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

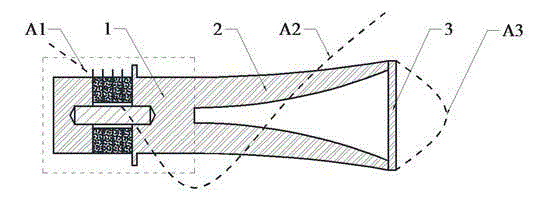

[0026] Such as figure 1 Shown is a schematic diagram of the first embodiment of the present invention. In this embodiment, the radial dimension of the output end of the variable-section metal tubular concentrator 2 is designed to be larger than the radial dimension of its input end, and its purpose is to connect the output end of the variable-section tubular concentrator with a smaller radial dimension. The large metal disc 3 serves as the sound radiation surface, thereby effectively increasing the ultrasonic radiation area of the sandwich piezoelectric transducer 1, and improving the impedance matching between the transducer and the load liquid, so that the ultrasonic energy is transmitted by the ultrasonic The transducer transmits to the load more effectively, which improves the ultrasonic radiation efficiency of the transducer; at the same time, the longitudinal displacement amplitude of the sandwich piezoelectric transducer 1 is adjusted by the variable cross-section met...

Embodiment 2

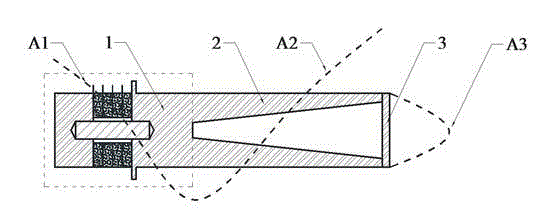

[0028] Such as figure 2 Shown is a schematic diagram of the second embodiment of the present invention. In this embodiment, the radial dimension of the output end of the variable-section metal tubular concentrator 2 is equal to the radial dimension of its input end, the radial dimension of the outer surface of the variable-section metal tubular concentrator 2 is constant, and the inner surface Conical changes. The structure compared to figure 1 Although the transducer shown does not increase the ultrasonic radiation area of the sandwich piezoelectric transducer 1, it can also improve the impedance matching between the transducer and the load liquid, effectively improving the sandwich piezoelectric ultrasonic transducer of the present invention. Displacement amplitude and ultrasonic radiation intensity of a composite transducer.

Embodiment 3

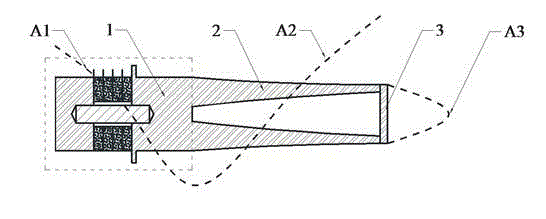

[0030] Such as image 3 Shown is a schematic diagram of the third embodiment of the present invention. In this embodiment, the radial size of the output end of the variable-section metal tubular concentrator 2 is smaller than the radial size of the input end, although this structural design is relatively figure 1 with figure 2 The transducer shown has a smaller ultrasonic radiation area, but the variable-section metal tubular concentrator 2 of the transducer with this structure has a larger area factor and amplification factor, so the transducer has a larger displacement amplitude and ultrasonic radiation intensity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com