Numerical control telescopic cushion with error compensation function

A technology of error compensation and stretch pad, which is applied in the field of blank holder force control in the workpiece stamping process, can solve the problems of high manufacturing cost and maintenance cost, excessive mold metal, and waste products, so as to reduce the length error requirement and prolong the service life Life and the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

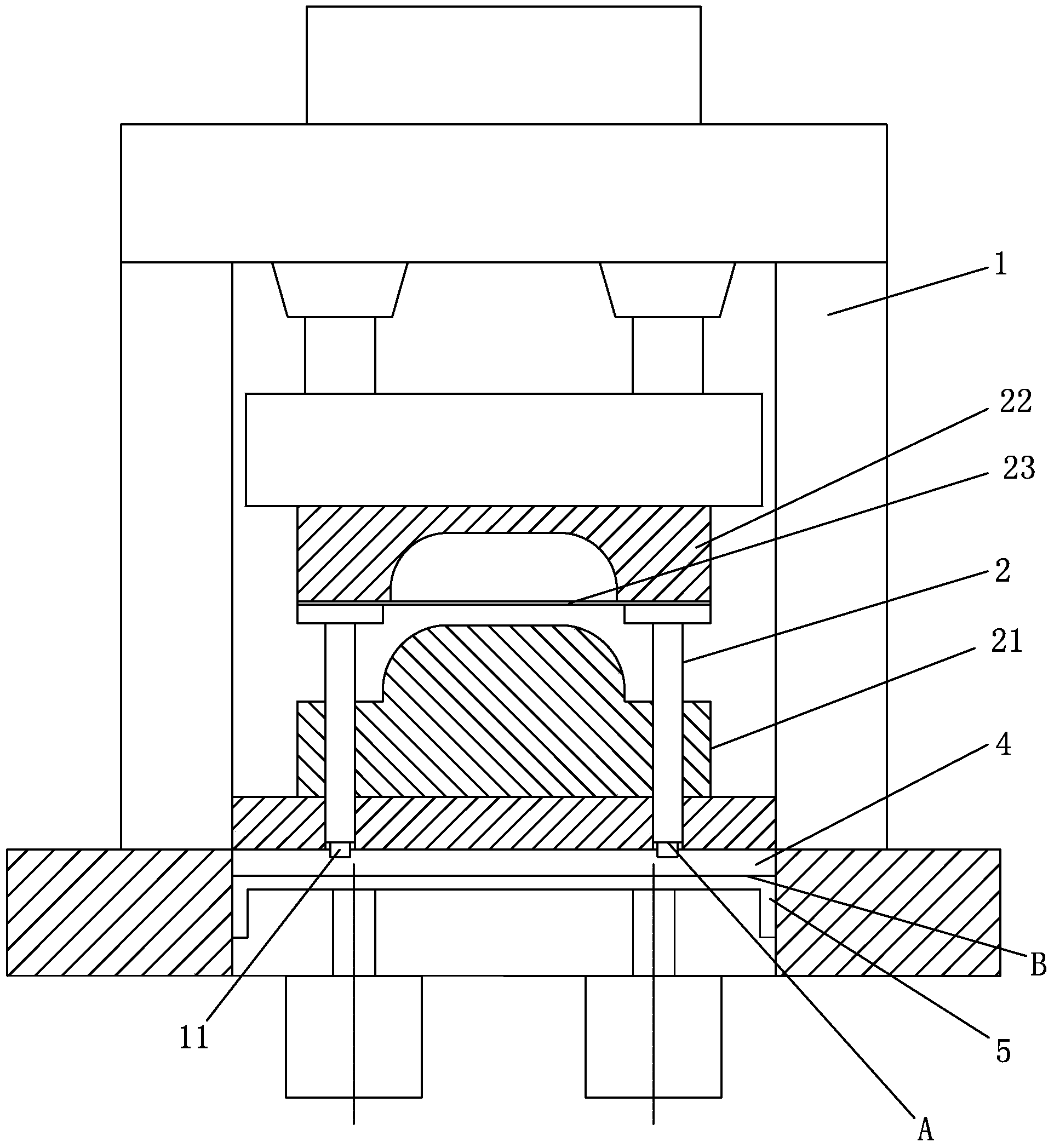

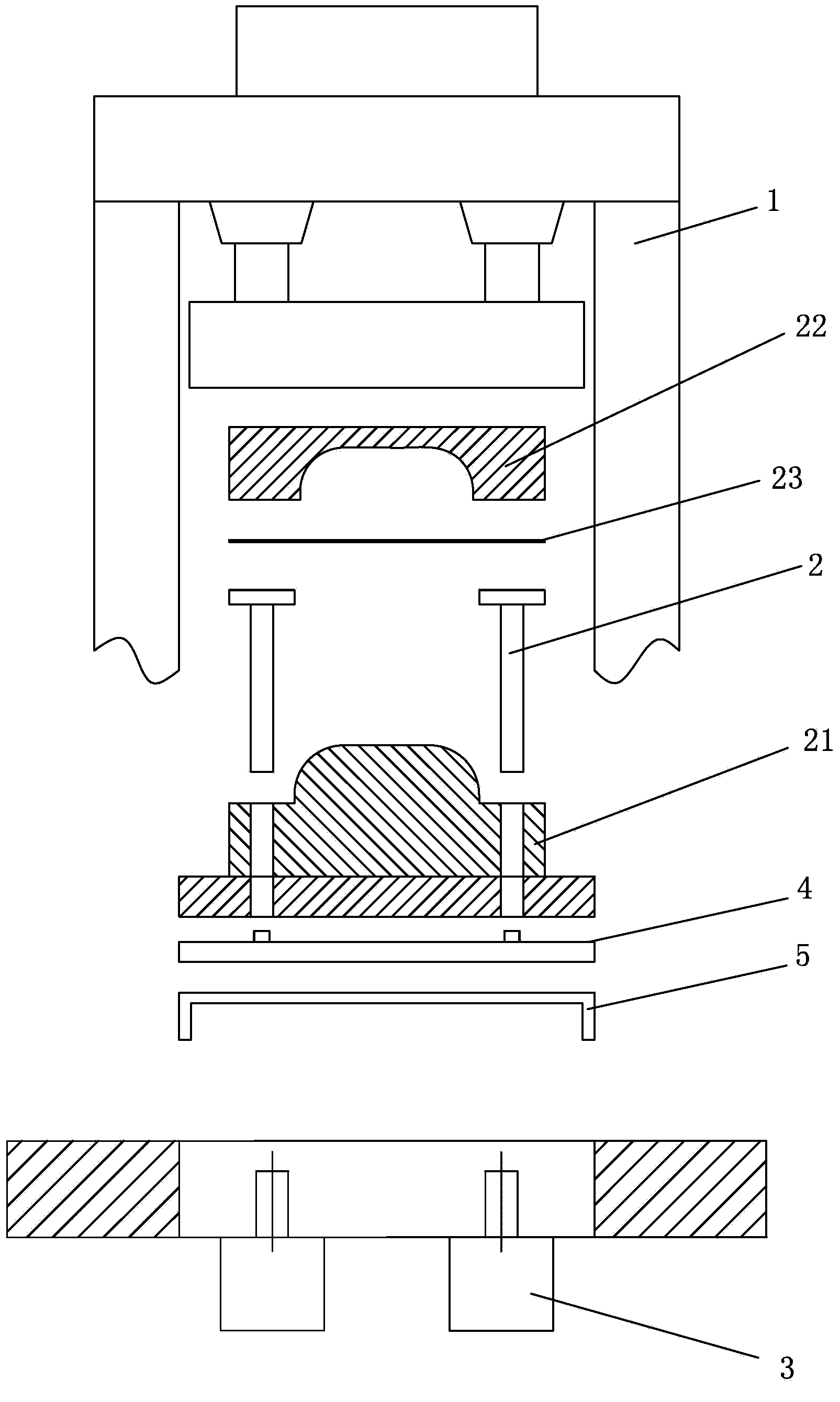

[0022] like figure 1 and figure 2 As shown, the numerically controlled stretch pad 4 of the present invention is installed between the ejector rod 2 of the press 1 and the press crown 5, and the fluid cylinder 11 of the numerically controlled stretch mat 4 is in direct contact with the ejector rod 2 ( figure 1 Middle A is the contact surface between the ejector rod and the top part of the numerically controlled stretch pad), and the bottom surface is directly in contact with the top crown 5 of the press ( figure 1 Middle B is the contact surface between the numerical control stretch pad 4 and the press stretch pad 5).

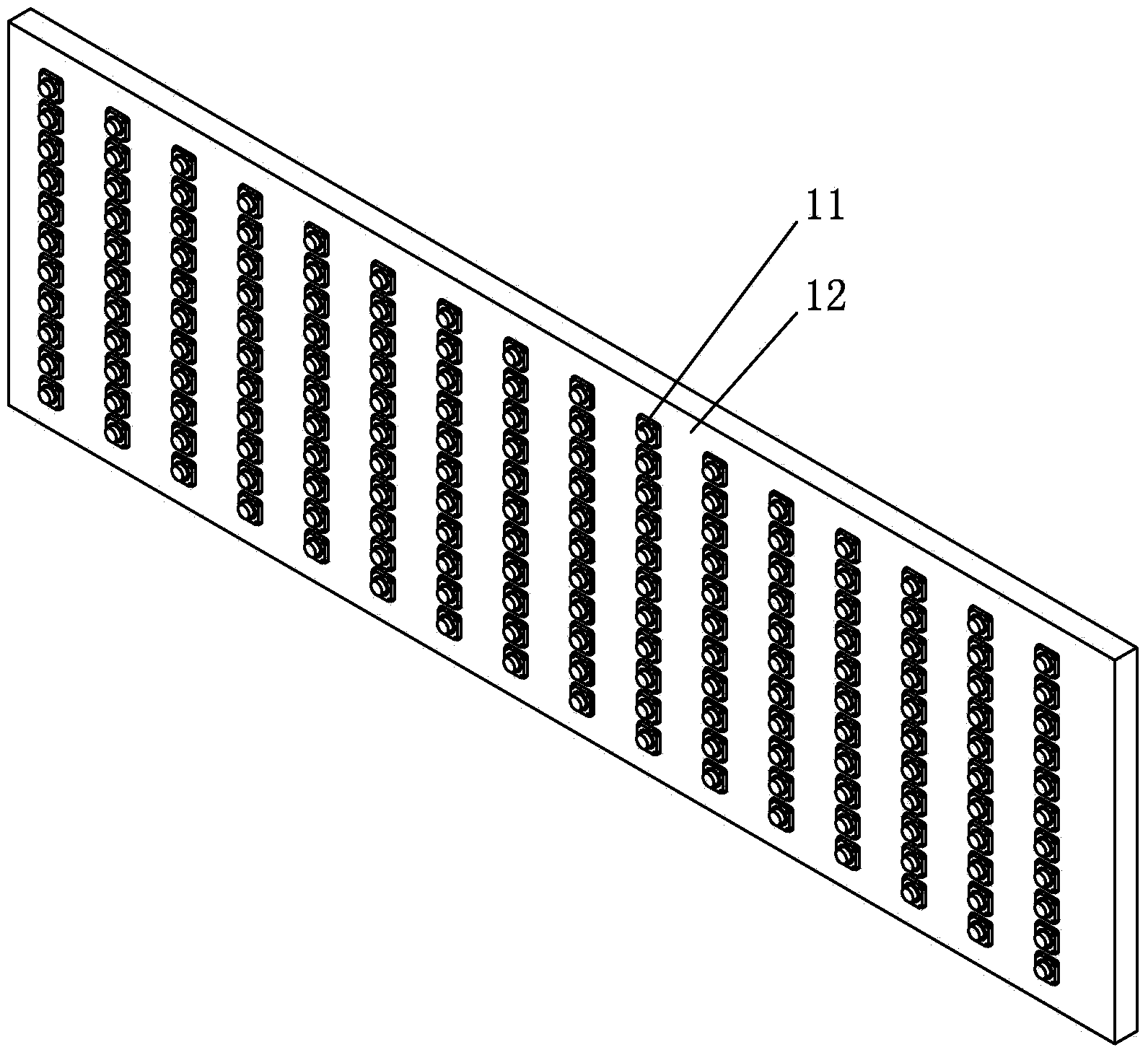

[0023] like image 3 As shown, the digitally controlled stretching mat of the present invention consists of a stretching mat base 12 and a fluid cylinder array 11 . The fluid cylinder array 11 is installed on the substrate, and is divided into 1-8 or more areas, and a plurality of fluid cylinders in each area are connected and communicated with each other, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com