Automobile airbag shell structure

An airbag shell and automobile safety technology, applied in vehicle safety arrangement, pedestrian/passenger safety arrangement, vehicle components, etc., can solve the problems of heavy weight, large deformation, complex structure, etc., and achieve good rigidity, low cost, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

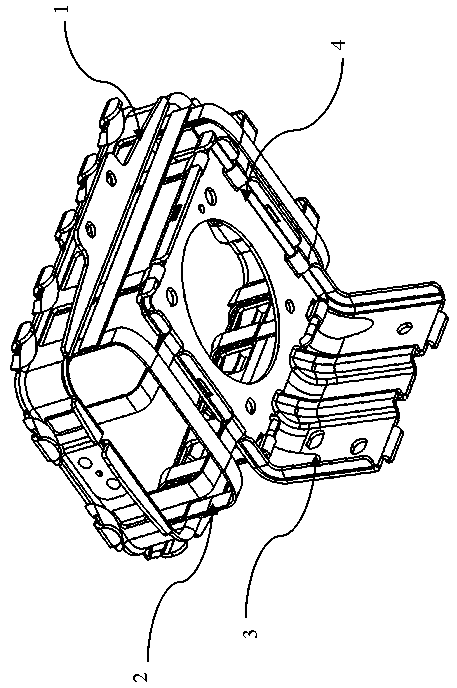

[0025] Such as figure 1 As shown, the automobile airbag housing structure involved in the present invention is composed of a metal frame 1, a webbing net 2 braided by webbing, a bracket 3 and a "U"-shaped steel wire 4, and the position of the bracket 3 corresponding to the webbing net 2 is provided with a mouth.

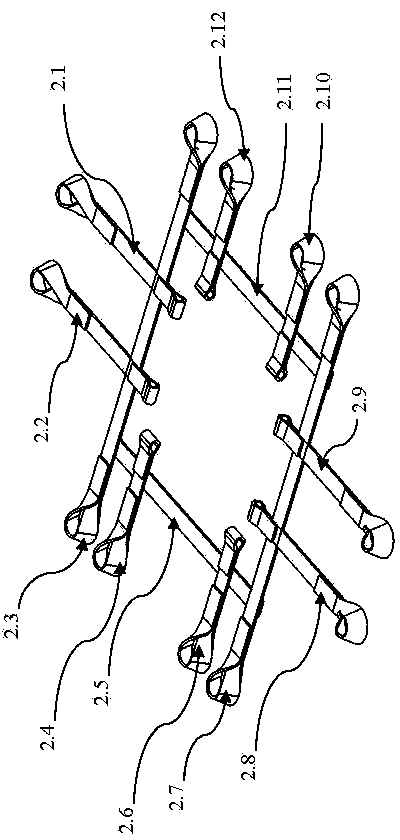

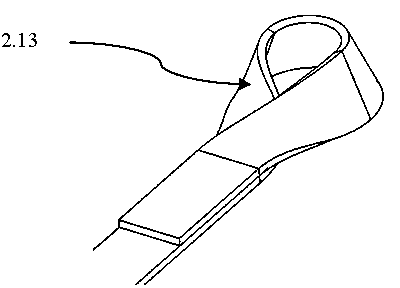

[0026] Such as figure 2 As shown, the ribbon net 2 is composed of right front ribbon 2.1, right rear ribbon 2.2, right connecting ribbon 2.3, rear right ribbon 2.4, rear connecting ribbon 2.5, rear left ribbon 2.6, left connecting ribbon 2.7, left rear ribbon 2.8, left front ribbon 2.9, the front left webbing 2.10, the front connecting webbing 2.11, and the front right webbing 2.12 are sewn together. Wherein, the two ends of the front connecting webbing 2.11 and the rear connecting webbing 2.5 are respectively sewn on the front and rear parts of the left connecting webbing 2.7 and the right connecting webbing 2.3, the front left webbing 2.10 and the front right we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com