Chassis type automatic brake gap adjusting mechanism of commercial vehicle

A disc brake and automatic adjustment technology is applied in the field of vehicle parts to overcome uneven braking force, enhance coordination and work stability, and increase protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

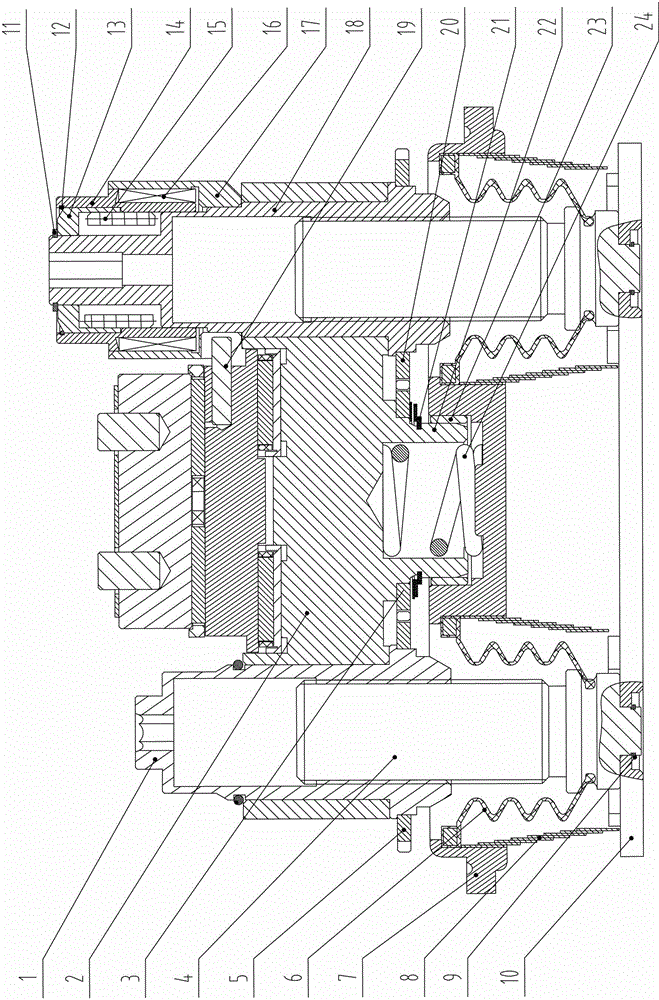

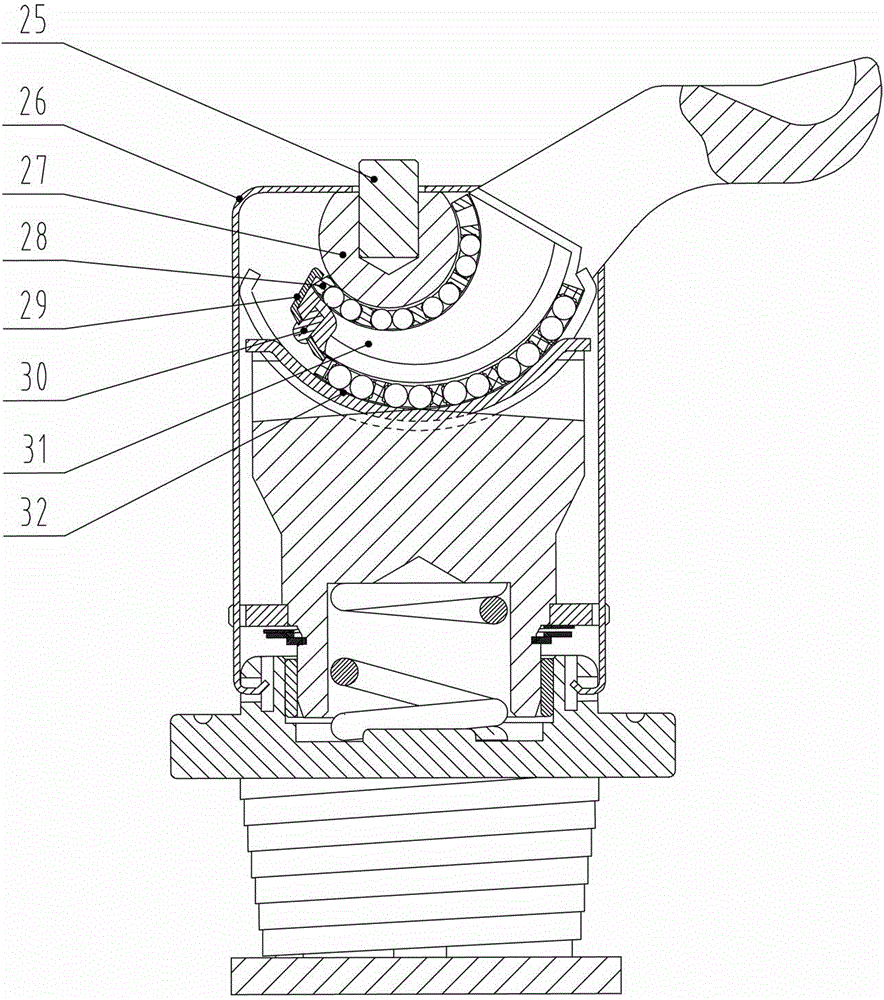

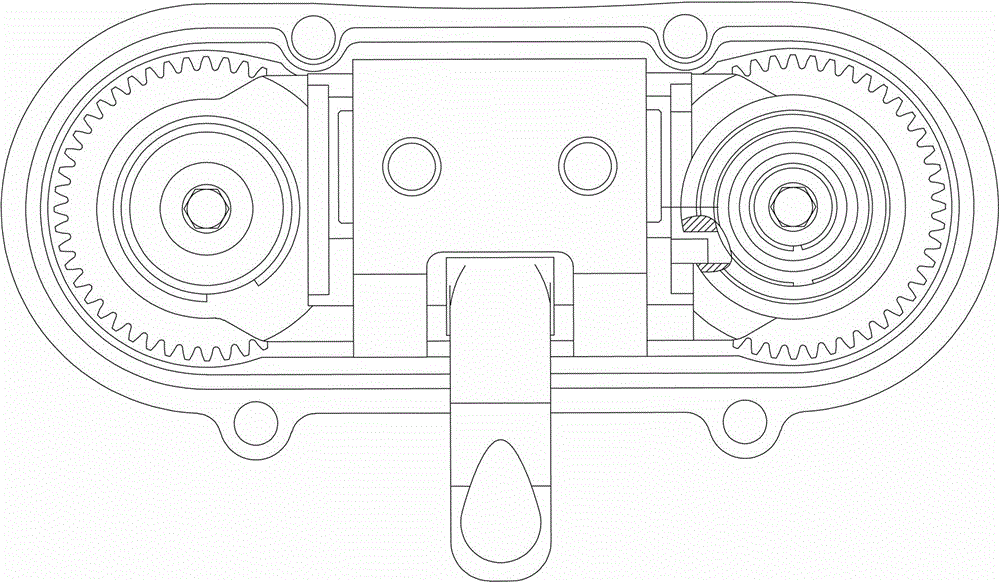

[0027] Below in conjunction with accompanying drawing and specific embodiment the patent of the present invention is described further:

[0028] The patent of the invention is shown in the figure,

[0029] An automatic disc brake clearance adjustment mechanism for commercial vehicles, including a cam-shaped pressure arm structure for transmission of braking power, a support seat is arranged under the pressure arm, and a main turning shaft and a slave turning shaft are set on both sides of the pressure arm structure. The rotating shaft and the secondary rotating shaft are provided with threads and an adjusting screw rod exposed at one end is installed. A transmission gear, a return spring and a bottom cover fixed to the brake are arranged under the support seat. It is characterized in that the main rotating shaft and the secondary rotating shaft are integrated. structure, the exposed end of the adjustment screw is provided with an integrated brake push plate; the pressure arm s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com