Flat-plate-type water sublimation cold plate for aerospace radiation

A flat plate, cold plate technology, applied in the field of spacecraft thermal control, can solve the problems that the system configuration cannot provide enough heat dissipation area, the system weight does not support active thermal control technology, and there is not enough compensation heating energy budget, etc., to achieve weight Light, reduce weight, reduce the effect of anti-requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

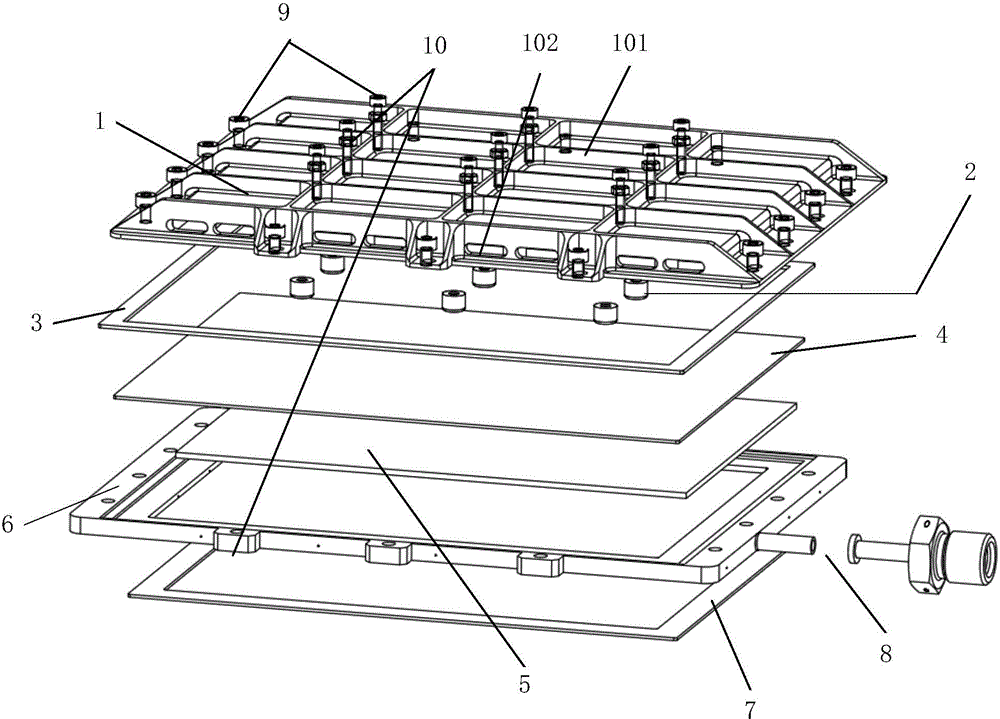

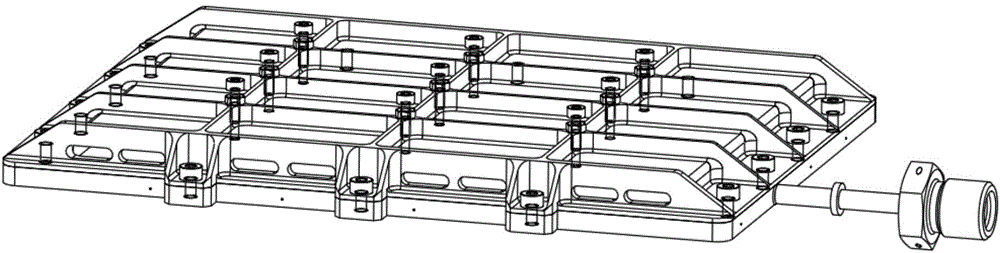

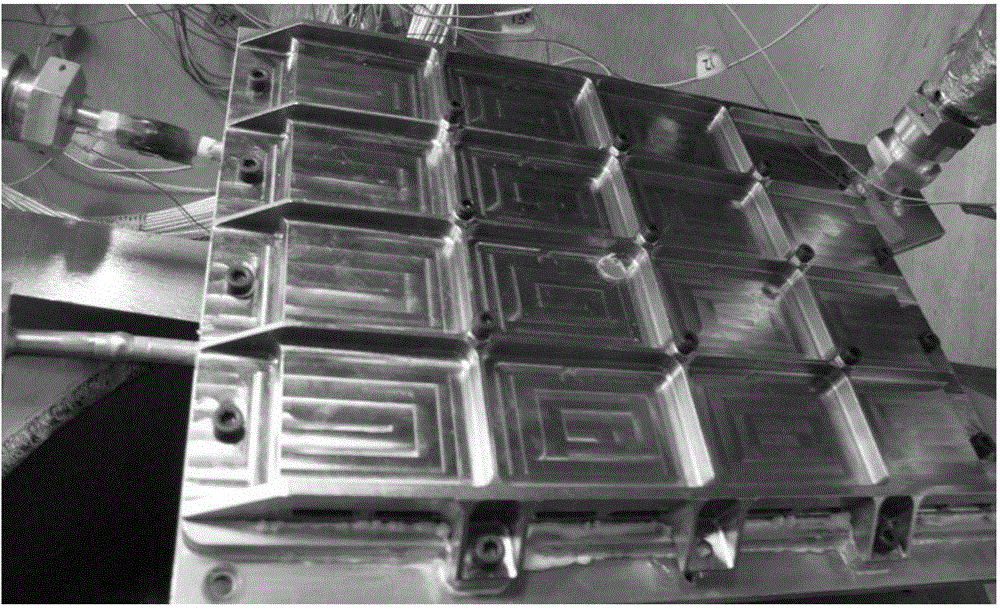

[0025] Such as Figure 1-3 As shown, the flat plate water sublimation cold plate for aerospace heat dissipation of the present invention mainly consists of a cover plate 1, a polytetrafluoroethylene pad 2, a sealing ring 3, a porous plate 4, a metal foam or a microporous fin 5, a substrate 6, a supply Consisting of a water channel seal plate 7, a water supply pipeline 8, connecting bolts 9 and locknuts 10;

[0026] The bottom surface of the base body 6 is provided with a circumferential water supply channel, the water supply channel sealing plate 7 is welded on the bottom surface of the base body 6, and the water supply pipeline 8 runs through the water supply channel; the upper surface of the base body is reserved with " step type" installation space matching with metal foam or microporous fin 5, porous plate 4 and sealing ring 3, the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com