Once-through cooling water supply system of steam turbine capable of being subjected to extraction condensing and back pressure operation

A direct-flow cooling and water supply system technology, applied to mechanical equipment, engine components, machines/engines, etc., can solve problems such as poor water distribution uniformity, unstable water outlet pressure, and large number of pipeline fittings, and achieve uniform water supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

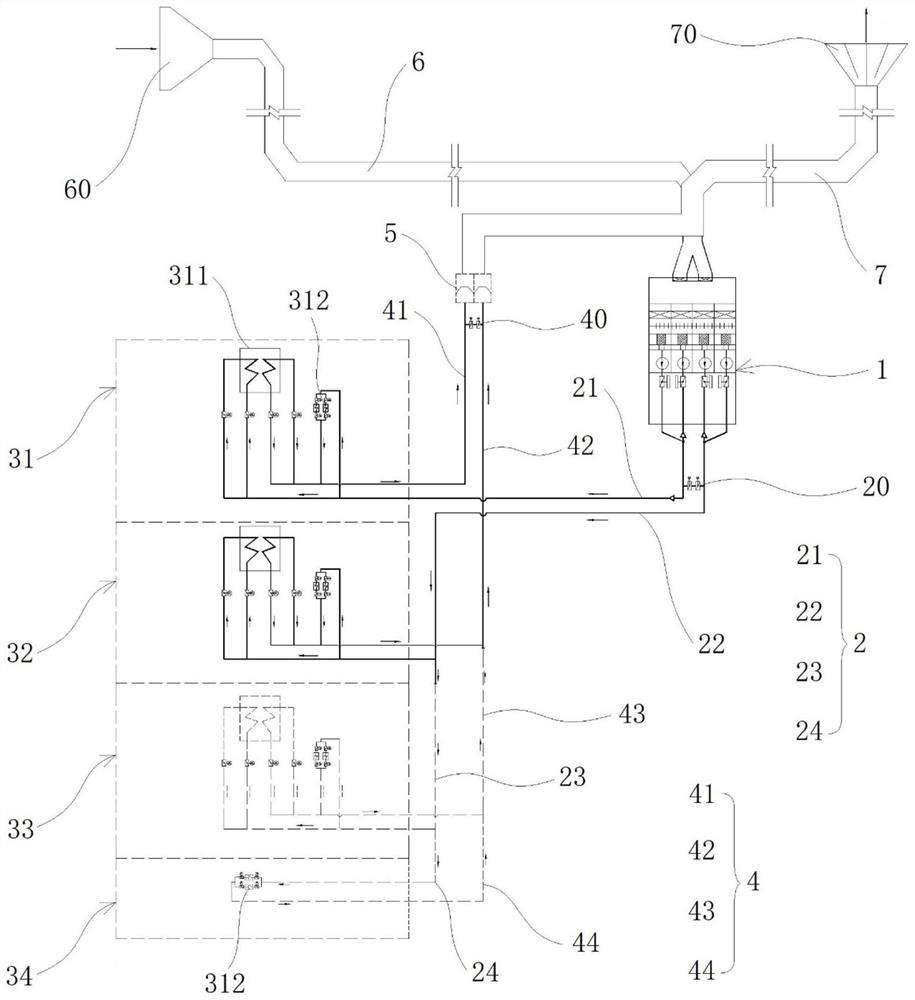

[0032] The specific embodiment 1 of the once-through cooling water supply system for the steam turbine that can be pumped and condensed and can be operated under back pressure is as follows: figure 1 As shown in the figure, the direct-current cooling water supply system of the steam turbine capable of extraction and back pressure operation includes a circulating water pump house 1, a water supply pipeline 2, a drainage pipeline 4, a No. 1 extraction-condensing unit condenser 31, and No. 2 extraction-condensing unit condenser 32, condenser 33 of No. 3 extraction condensation unit, and auxiliary cooler 34 of No. 4 back pressure unit; water supply pipeline 2 includes a first water supply pipe 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com