A 1/3 sector spiral folded baffle heat exchanger

A baffle and heat exchanger technology, which is applied to the heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc. Effect of medium flow rate, thermal performance factor improvement, and heat transfer performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

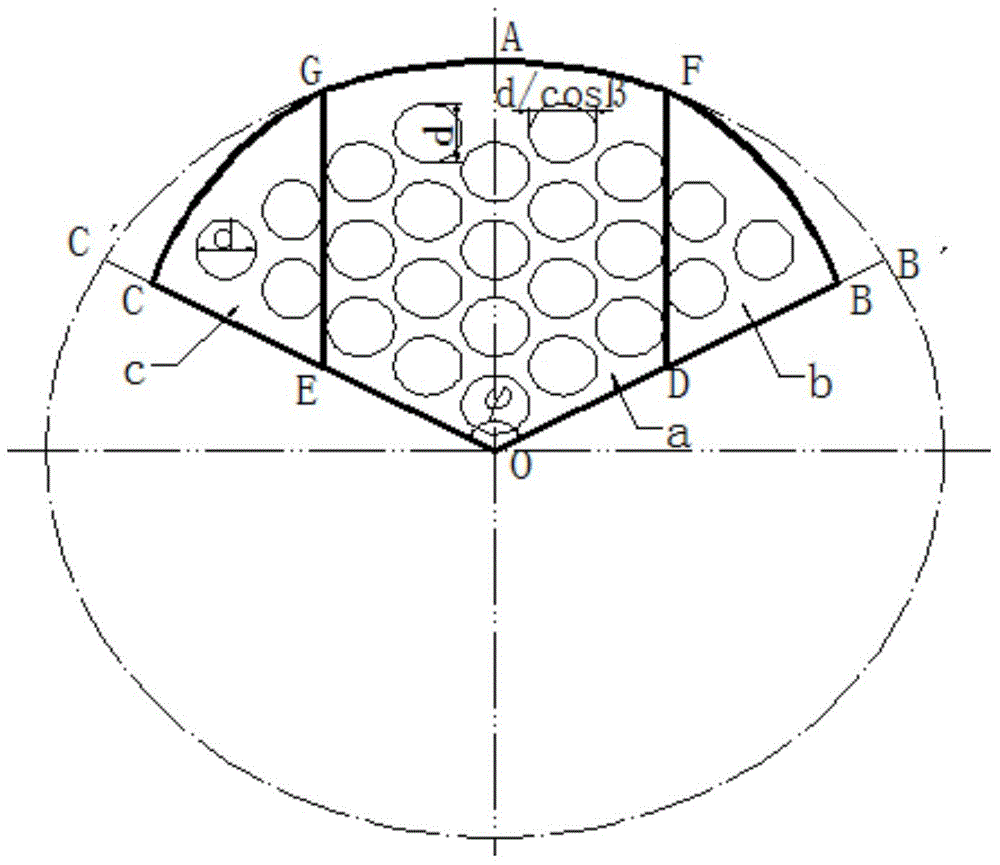

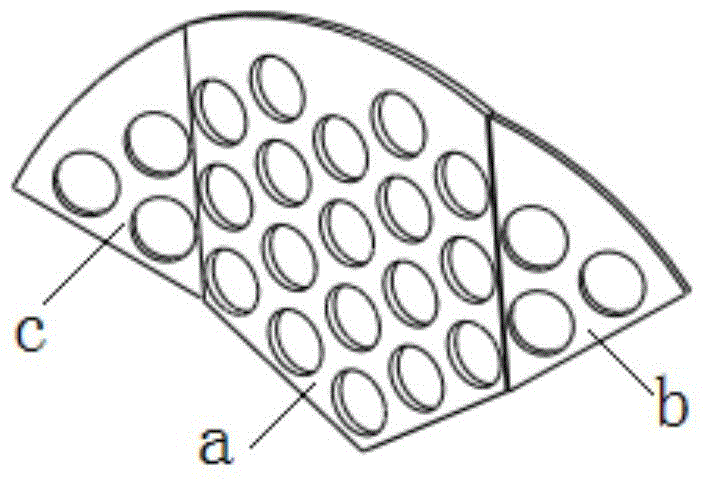

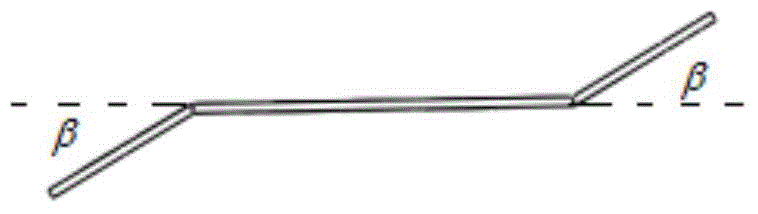

[0017] Referring to Figure 1 and figure 2 , a 1 / 3 fan-shaped spiral baffle heat exchanger, including 1 / 3 fan-shaped baffles, 1 / 3 fan-shaped baffles are cut from a standard ellipse, 1 / 3 fan-shaped baffles The two straight sides of the surface baffle are equal and symmetrical to the minor axis of the standard ellipse, and the angle between the 1 / 3 fan-shaped baffle It is greater than 120°, and only changes with the helix angle β of 1 / 3 fan-shaped plane baffle as follows: The plane profile of the 1 / 3 fan-shaped plane baffle is determined by the arc and two straight sides OB′, OC′, and the equation of the standard ellipse satisfies That is, the major axis diameter a and the minor axis diameter b of the ellipse are respectively a=D / cosβ, b=D, and the 1 / 3 fan-shaped baffle is based on the 1 / 3 fan-shaped plane baffle. The straight line (FD or GE) corresponding to tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com