Blow-moulding machine with base cooling in the stabilisation phase

An internal, time-segmented technology, applied in the direction of household appliances, hollow objects, other household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

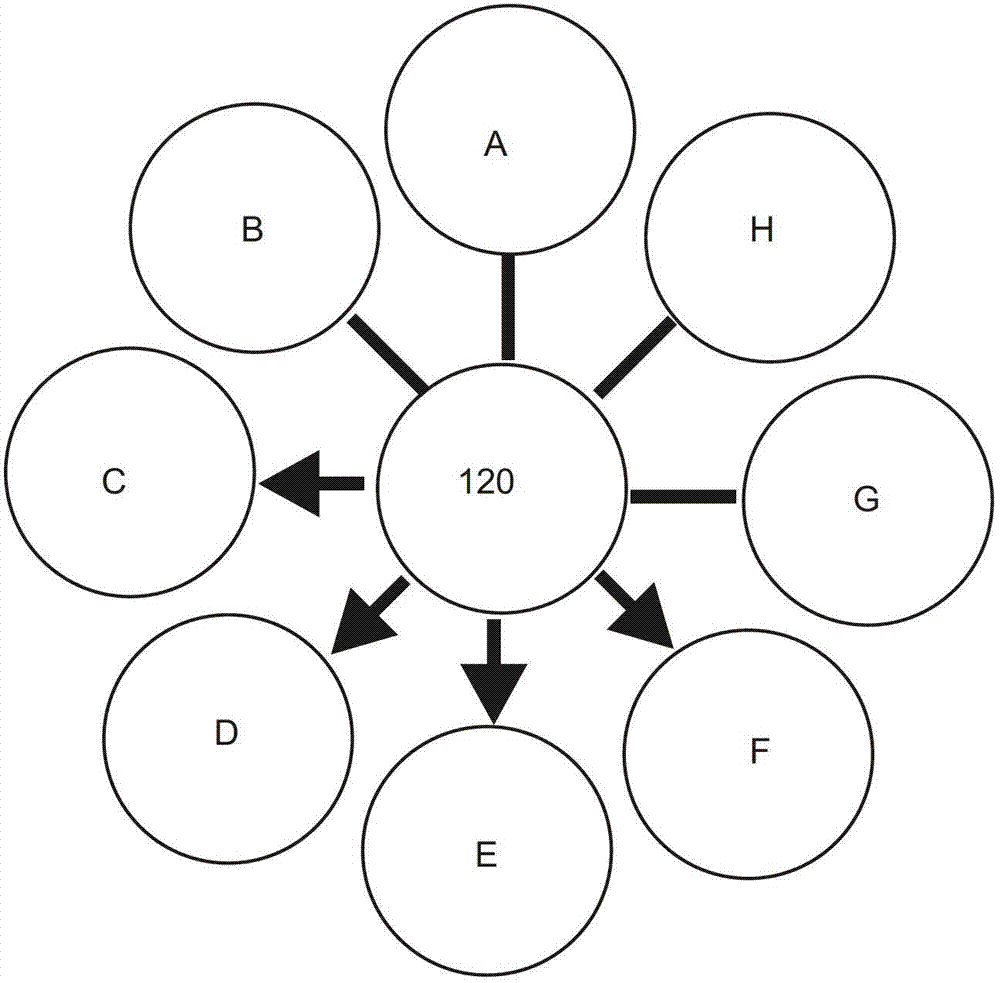

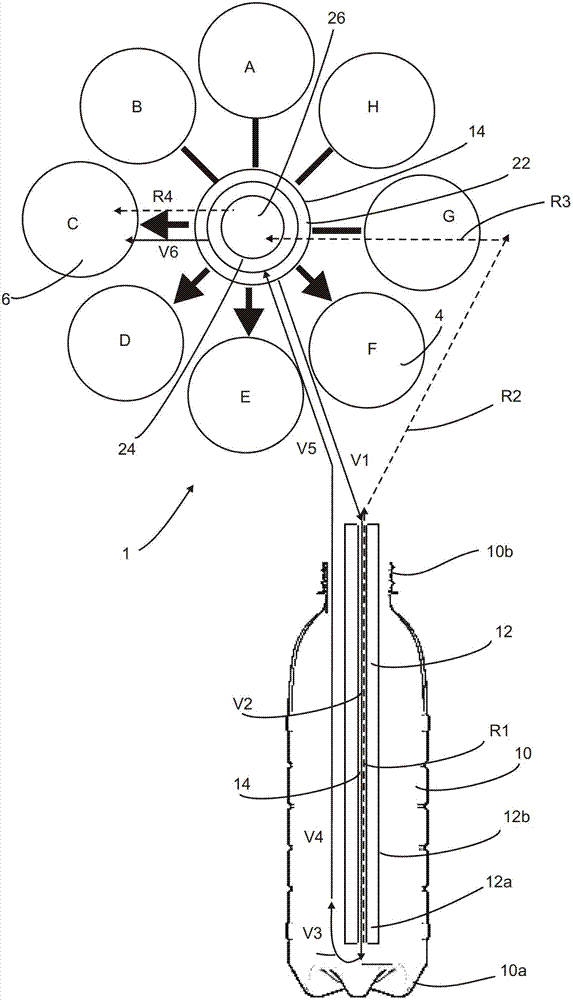

[0083] figure 1 is a rough schematic diagram of the sequence of methods according to the prior art. In this case, a blow molding machine with eight stations A-H is shown roughly schematically. In this case (also in figure 2 ), the letters indicate the following states of the method:

[0084] A: Open the blow mold;

[0085] B: transfer of the plastic preform into the blow mold;

[0086] C: forming a container - especially by applying pressure to it;

[0087] D: The container is complete and held under pressure;

[0088] E: The container is complete and held under pressure;

[0089] F: The container is complete and held under pressure;

[0090] G: The container is lowered (released from pressure);

[0091] H: Transfer the finished container out of the blow mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com