A battery pressing device

A technology for press-fitting devices and batteries, which is applied in transportation and packaging, metal processing equipment, vehicle parts, etc. Installation efficiency and other issues to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

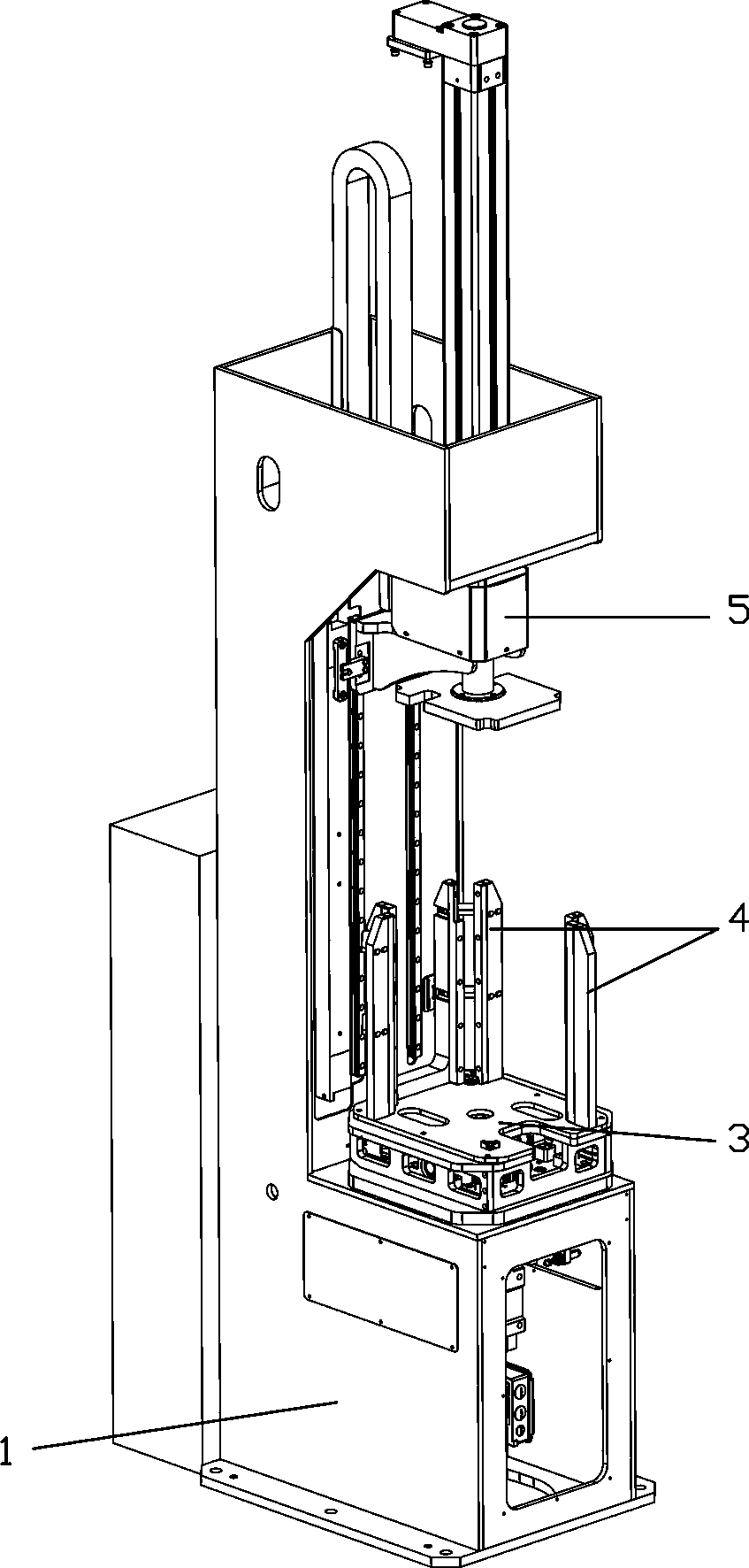

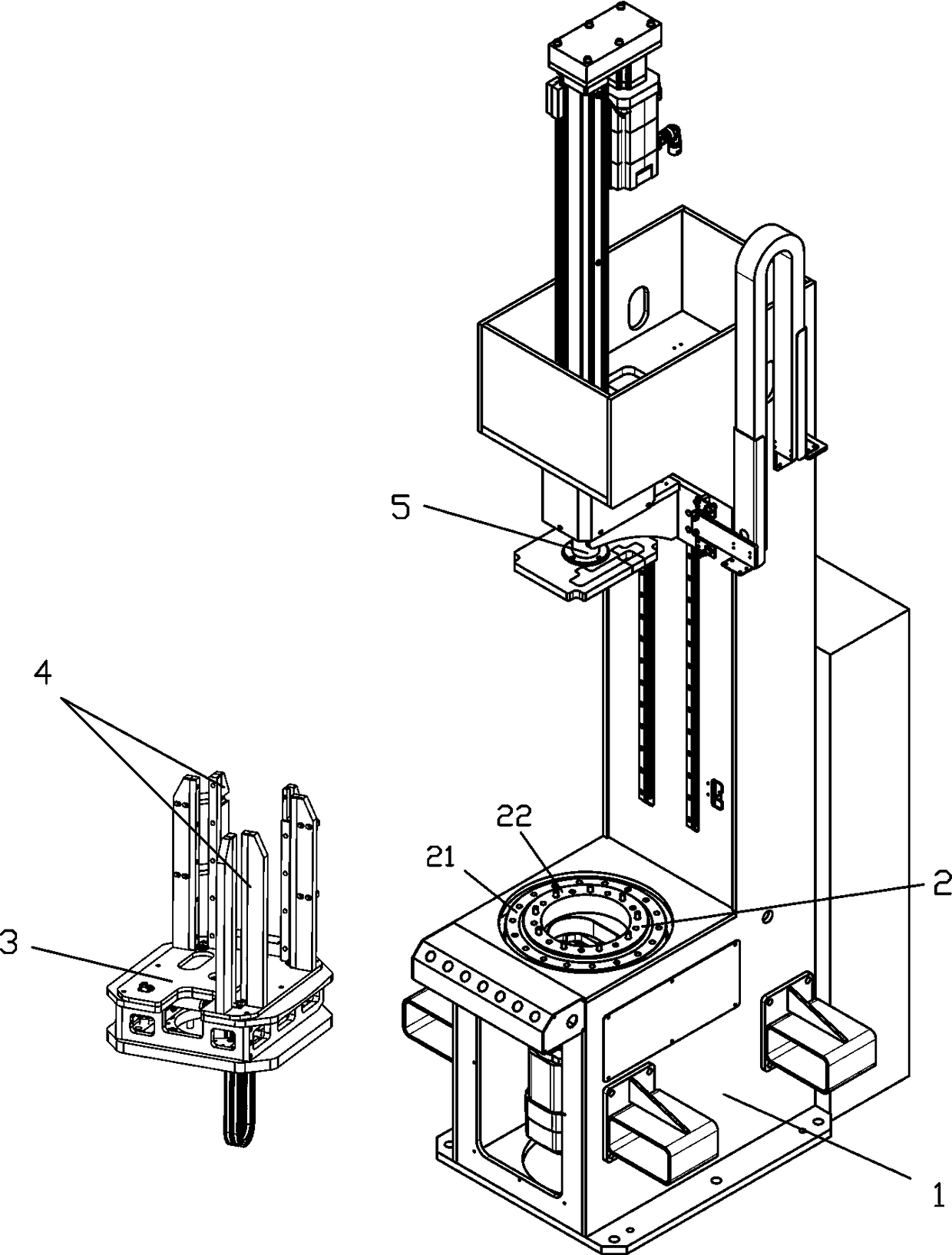

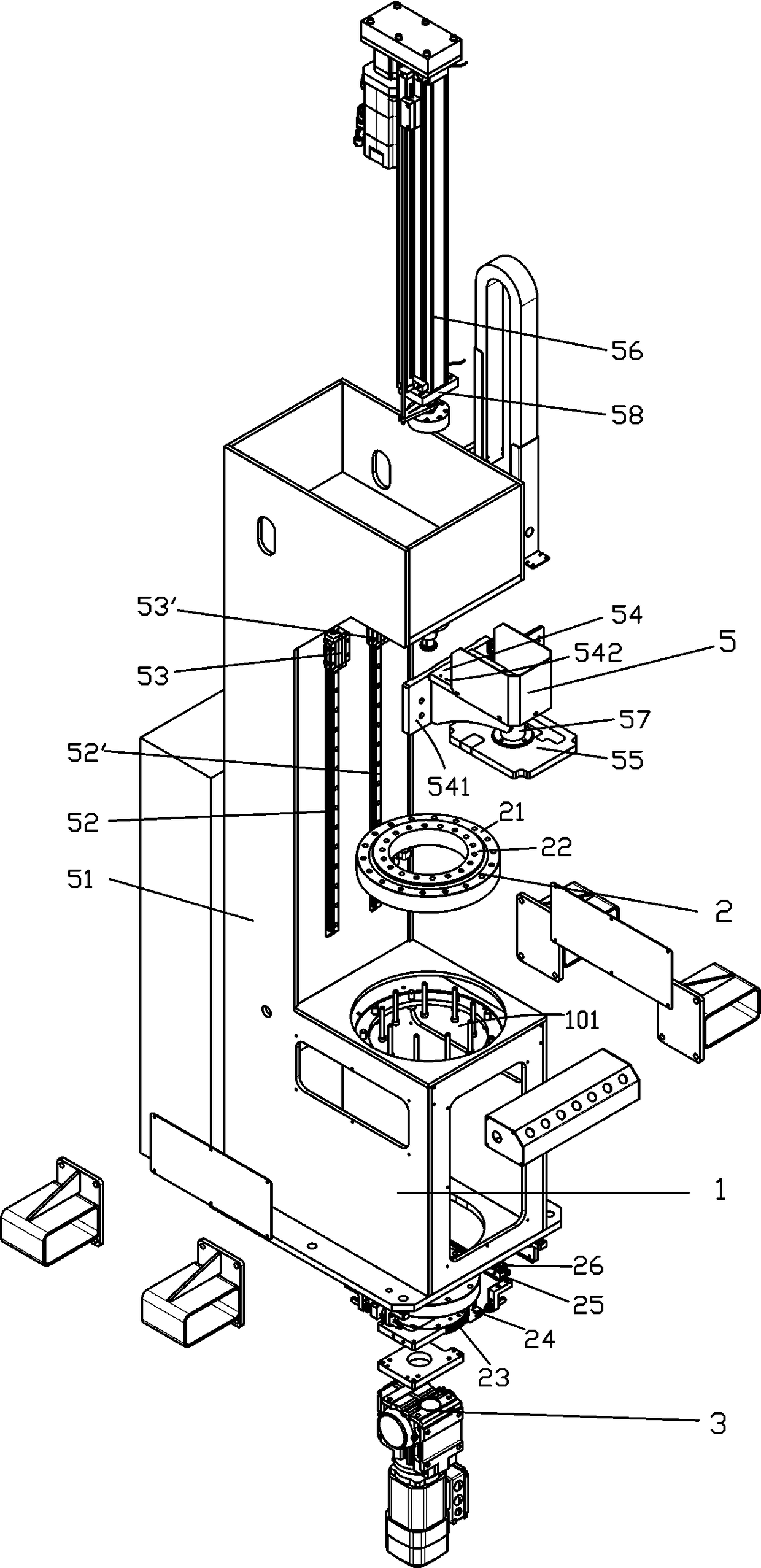

[0027] see Figure 1 to Figure 12 , a battery pressing device of the present invention, which includes,

[0028] The base 1 is a shell structure with a through hole 101 in the center of the upper end surface;

[0029] The rotary mechanism 2 is arranged in the base 1, which includes,

[0030] The fixed ring 21 and the movable ring 22 matched therewith, the fixed ring 21 is fixed at the through hole 101, and the movable ring 22 is movably arranged inside the fixed ring 21;

[0031] The drive plate 23 is connected to the bottom surface of the movable ring 22, the center of the drive plate 23 is provided with a through hole 231, and one side of the drive plate 23 is an arc surface 232 with teeth;

[0032] The drive bar 24, one side 241 of which is a rack, meshes with the toothed arc surface 232 of the drive plate 23;

[0033] The slide rail 25 and the slide block 26, the slide block 26 is arranged on the inner wall of the side of the base 1 close to the drive bar 24 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com