Valve regurgitation test water injection system in mitral valve repair

A water injection system and mitral valve technology, applied in the direction of heart valves, etc., can solve the problems of inability to recycle normal saline, increase the workload of medical staff, and affect the operation time, so as to improve the detection accuracy, reduce the risk of heart injury, and reduce the risk of heart damage. The effect of operating volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

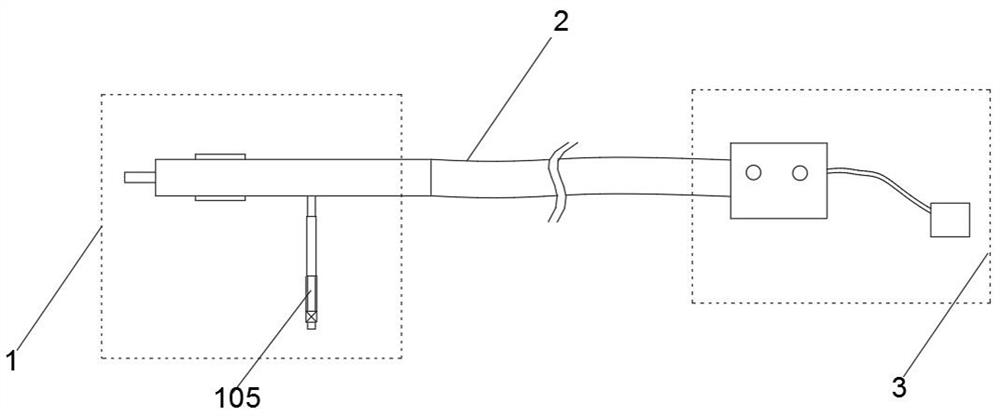

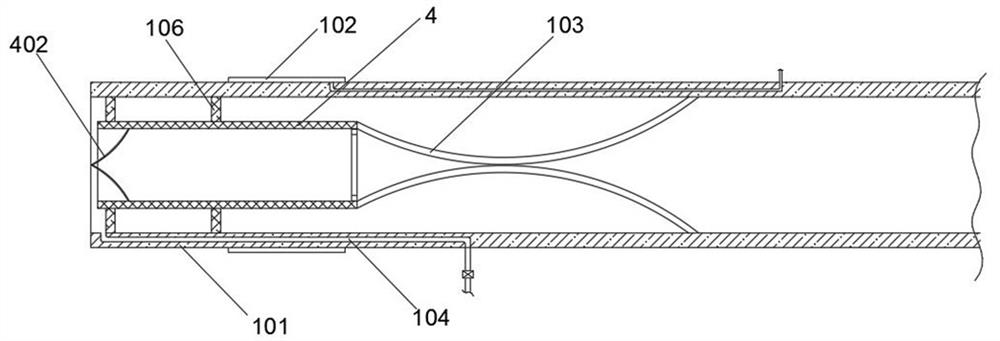

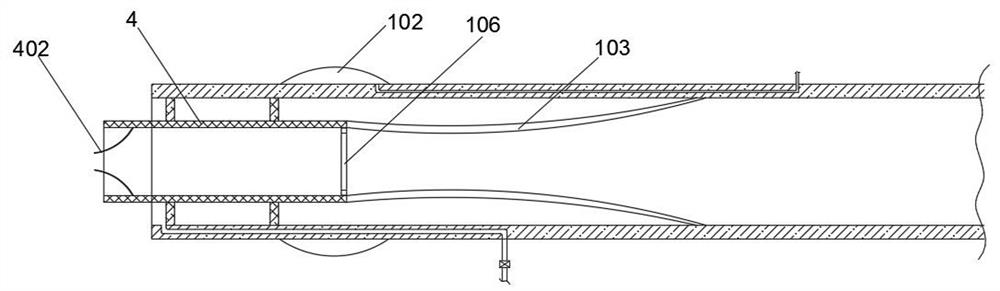

[0037]A water injection system for valve regurgitation testing in mitral annuloplasty described in this embodiment includes a catheter and a water delivery component connected to one end of the catheter, wherein the water delivery component includes normal saline and provides pressure to pump the normal saline The supply part that enters the heart. In this embodiment, a syringe is used. The syringe is connected with a quantitative pump to provide the system with a controllable amount of physiological saline. A valve regurgitation test water injection system in mitral annuloplasty in the present invention also includes a water injection assembly 1 arranged at the other end of the catheter and inserted into the inner side of the heart valve. The water injection assembly 1 includes a casing 1 integrally connected with the catheter and The telescopic element arranged in the housing 1. Wherein the telescopic member is connected to the inner surface of the housing 1 through an arc-s...

Embodiment 2

[0042] The specific structure of the valve regurgitation test water injection system in the mitral annuloplasty described in this embodiment is basically the same as that of the valve regurgitation test water injection system in the mitral annuloplasty described in Embodiment 1, and it is different The difference is that a sealing sheet 107 is provided at the center of the arc-shaped elastic sheet 103, and the sealing sheet 107 can be fixed on the water blocking plate 401 through the support rod 108, and the circumference of the sealing sheet 107 is close to the middle of the arc-shaped elastic sheet 103 and shrinks. inside side of the place. The setting of the sealing sheet 107 further improves the sealing performance of the water injection assembly 1 in the system, thereby effectively avoiding liquid leakage in the water injection assembly 1 when the water delivery assembly is not working. In this embodiment, the free end of the housing 101 of the water injection assembly 1 ...

Embodiment 3

[0044] The specific structure of the valve regurgitation test water injection system in the mitral annuloplasty described in this embodiment is basically the same as that of the valve regurgitation test water injection system in the mitral annuloplasty described in Embodiment 1, and it is different The advantage is that the supply part that provides a controllable amount of physiological saline for this system adopts a one-way hand-held squeeze ball 6, and the physiological saline in the storage chamber 5 is continuously supplied to the water injection through the doctor's squeeze of the one-way hand-held squeeze ball 6 components and then injected into the heart. The liquid inlet end of the one-way hand-held squeeze ball 6 is also provided with a pressure relief pipe 8, and the pressure relief pipe 8 is provided with an elastic diaphragm 801, and the inner wall of the pressure relief pipe 8 is opposite to the elastic diaphragm 801. A limit block is arranged, The liquid outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com