Water-source heat-pump composite system

A water-source heat pump and composite technology, which is applied in heat pumps, lighting and heating equipment, refrigeration components, etc., can solve the problems that the heat exchange area of the independent heat exchange source cannot be used, the economy and practicability are low, and improve the economy. and practicality, the effect of improving the economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

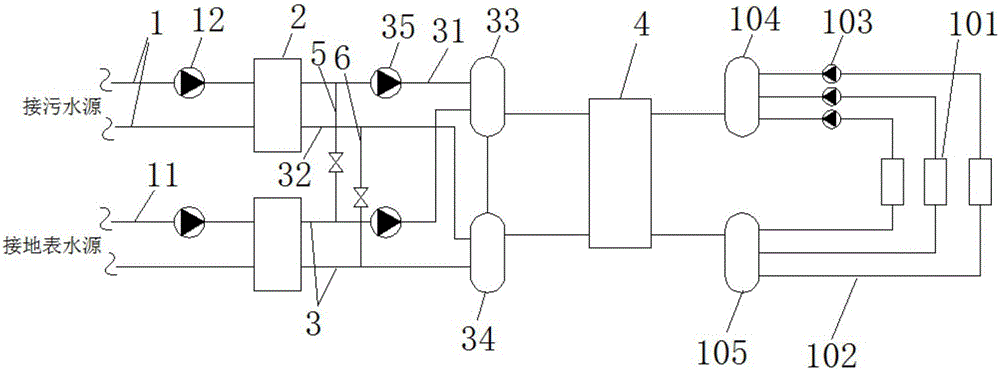

[0057] Such as figure 1 As shown, this embodiment provides a water source heat pump composite system, which includes a circulating water system and a heat pump unit 4. Among them, there are at least two circulating water systems, and each circulating water system includes a water intake circulating pipe 1, a heat exchanger 2 and an intermediate water circulating pipe 3. Wherein, the heat exchanger 2 in each circulating water system is respectively connected with the water intake circulation pipe 1 and the intermediate water circulation pipe 3 to realize the heat exchange between the water in the water intake circulation pipe and the intermediate water in the intermediate water circulation pipe. . The heat pump unit 4 is connected to the intermediate water circulation pipeline 3 of each circulating water system, and is used to transfer the heat of the intermediate water to the heat pump unit 4. The intermediate water circulation pipeline 3 includes a first pipeline 31 and a sec...

Embodiment 2

[0059] Such as figure 1 As shown, this embodiment provides a water source heat pump compound system. Compared with the previous embodiment, the first pipe 31 of the intermediate water circulation pipe 3 in this embodiment is also provided with a water collector 33 to allow The intermediate water after heat exchange in the heat exchanger 2 flows through the water collector 33, and then flows into the heat pump unit 4 for heat exchange heat treatment. The second pipeline 32 of the intermediate water circulation pipeline 3 is also provided with a water separator 34, so that the intermediate water after heat exchange by the heat pump unit 4 flows through the water separator 34, and then flows into the corresponding heat exchanger 2 for heat exchange treatment. .

[0060] In this embodiment, through the above arrangement, the intermediate water of different intermediate water circulation pipelines 3 flows into the water collector 33, and then flows into the heat pump unit 4 at a const...

Embodiment 3

[0063] This embodiment provides a water source heat pump compound system. Compared with the above embodiment, there are two circulating water systems in this embodiment, specifically a first circulating water system and a second circulating water system. Among them, the water intake circulation pipeline of the first circulating water system is a sewage circulation pipeline, and the water intake circulation pipeline of the second water circulation system is a surface water circulation pipeline.

[0064] The sewage water source or the surface water source flows through the heat exchanger through the sewage water intake pump 12 or the surface water intake pump respectively, transfers heat and returns to the sewage water source or surface water source, and the intermediate water that exchanges heat with the water source in the heat exchanger passes through the intermediary The water pump flows into the water collector 33 and from the water collector to the heat pump unit 4. After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com