A method for measuring dielectric constant and liquid level of medium in lng gas tank

A dielectric constant and gas tank technology, applied in the field of measurement, can solve problems such as changes in full-load capacitance, affecting the dielectric constant of liquids and gases, calibration, etc., and achieve the effect of accurate dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

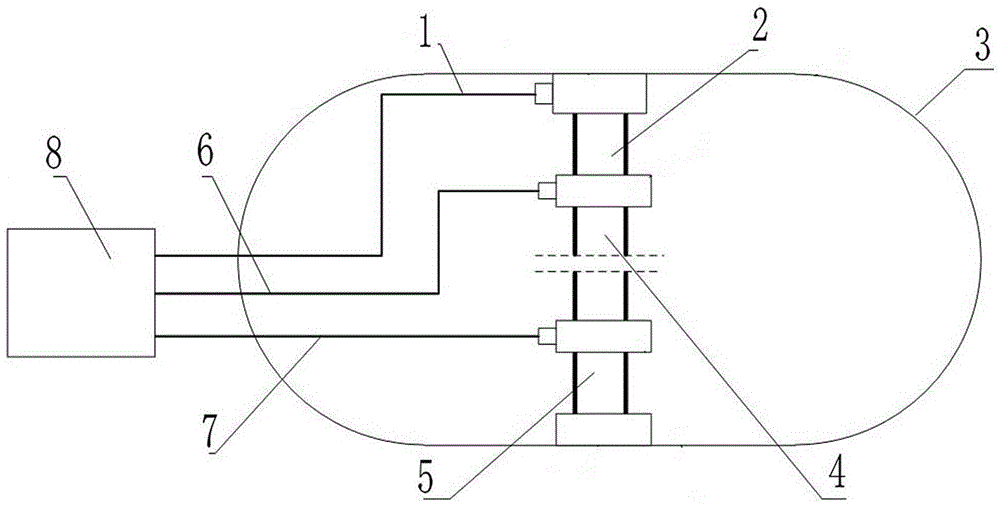

[0019] Attached below figure 1 The utility model is described further.

[0020] The method for measuring the dielectric constant and liquid level of the medium in the LNG gas tank comprises the following steps:

[0021] (1) The top capacitor 2, the middle capacitor 4 and the bottom capacitor 5 are respectively arranged at the upper end, the middle part and the lower end of the LNG gas tank 3, and the top capacitor 2, the middle capacitor 4 and the bottom capacitor 5 are all inner tubes and the outer tubes are For coaxial capacitors that are circular and have the same radius, the radius of the inner tube of the top capacitor 2 , the middle capacitor 4 and the bottom capacitor 5 is r, and the radius of the outer tube is R. (2) The top capacitor 2, the middle capacitor 4 and the bottom capacitor 5 respectively measure their capacitance values in the air, which are C H1 、C M1 and C L1 , capacitance value C H1 、C M1 and C L1 They are respectively transmitted to the signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com